(394 products available)

Tools in a machining system should be sturdy, reliable, and versatile. A weldon tool holder fulfills these requirements and does so in a variety of ways.

Universal Magnetic Holders:

Equipped with a single, strong magnet, they are generally rectangular-shaped plates that weld to other flat, ferrous surfaces. Their use is inexpensive, empowering the operator to transform a tool to do different kinds of jobs. However, without manual intervention, it cannot hold a tool at an angle or offset.

Multi-Directional Magnetic Holders:

A more advanced version, these contain more than one magnetic pole. Magnetic grips are the most adaptable of all holders. Depending on the number and strength of the poles, they can hold a tool at numerous angles and offsets. Their magnetic strength is adjustable, allowing control over the grip's strength. For precise machining applications, they can offer a superior level of versatility and precision. One of the drawbacks is the increased complexity in control and possibly more rapid wear that can occur with frequent adjustment.

Mechanical Tool Holders:

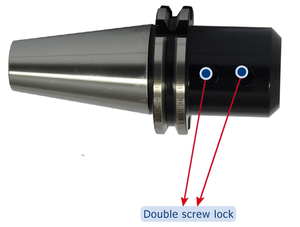

They are magnetic holders with a mechanical fastening system, like screws or clamps. They are suitable for use with tools with irregular shapes or sizes that cannot be properly held by a magnetic holder.

In addition, optical or laser tool holders use optical beams to detect the position of the tool, providing a non-contact method of tool sensing. Another possibility is the solid tool holder, which has a fixed size and shape and is used to hold tools with a specific shank size and geometry.

Tool holders are designed to hold the tools tightly, ensuring proper performance during machining operations. The following specifications of tool holders are critical for ensuring the proper performance of the equipment when used with different machining operations.

Weldon tool holders require maintenance to ensure they work properly and their longevity. Here are some weldon tool holder maintenance tips:

The weldon tool holder finds applications in various industries. It is mostly used in industries that carry out heavy-duty machining operations. Below are some usage scenarios of the weldon tool holder.

When choosing the weldon tool holders for any machinery application, there are a few things to consider. First, the spindle taper is important because it determines whether or not the tool holder will fit properly on the machine. Among many others, CAT, BT, and NK are common spindle tapers that have wide applications. Tool holders can be designed to fit any spindle taper.

Secondly, the shank size should be compatible with spindle size except when reduction tools are used. The dedicated drive places the amount of torque transmitted to the shank. This amounts of torque arises from form-fit connections, friction, and interference in fit, with numerous contact points but no rotating elements. This is some of the extensive tool holder mystery that is widely known but is essential to practice for adequate productivity and safety.

Third, the length of the tool holder must be considered. Longer holders allow more clearance and reach but sacrifice rigidity. Shorter ones provide superior rigidity but limit reach. Fourth, collet holders allow easy tool changes and facilitate tooling retention with locking nuts but lack concentricity precision.

Examine each tool holder's run-out, gripping force, length, change speed, and mass to choose the appropriate one based on machine compatibility and application requirements.

Last but not least, tool holder material is crucial to performance and durability. Usually made of high-carbon alloy steel, tool holders feature different coatings or treatments to improve strength, wear resistance, and corrosion resistance.

Q: What advantage does a straight weldon holder provide?

A: Straight weldon tool holders are cost-effective and provide adequate grip and retention. They are widely used in various machining applications because of these.

Q: Can one weldon tool holder universally fit all tools?

A: No, it cannot. Tool holders are designed to fit certain tools and machines. Apart from size compatibility, there is also a need to ensure proper grip, retention, and alignment.

Q: What standard do most tool holders fit?

A: Most tool holders conform to ANSI and JIS standards. These ensure compatibility with widely used machines and tools, making them ideal for industrial applications.

Q: Do tool holders wear out over time?

A: Yes, like any mechanical component, tool holders can wear out over time, especially with regular use, improper maintenance, or if they are not aligned correctly.