(5928 products available)

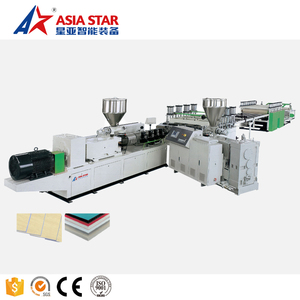

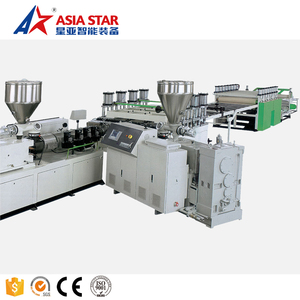

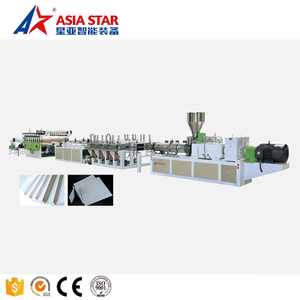

A wall foam insulation machine is a specialized device used to apply foam insulation in walls. Different types of wall insulation machines are available to meet distinct specification needs. Here are some of them:

Air compressor wall foam insulation machine:

This insulation machine applies foam to fill the empty space within walls, providing insulation and soundproofing qualities. It uses a portable air compressor as its source of power and pairs with a gun that dispenses foam when the trigger is pulled. Air compressor foam kits may come with varying sizes of foam cans.

Multi-kit wall foam insulation machine:

This machine is versatile and can be used for various applications. It effectively tackles gaps and cavities while simultaneously sealing off air leaks. One prominent feature of multi-kit wall insulation foam machines is that it works with multiple foam types.

Some of them include open-cell foam, which has a noticeable cell structure and is mostly filled with air, and closed-cell spray foam, which has a rigid, dense structure entirely filled with gas. The multi-kit works with different foam types as it is designed to accommodate distinct formulations.

Warm air wall foam insulation machines:

This machine operates by using heat from a built-in element within the device. The heat activates the foam components, which begin expanding and filling the spaces within the wall cavities when mixed together. This unique feature allows the operator to insulate an area quickly.

Propellent wall foam insulation machines:

These machines use a propellant to atomize the foam components in the spray nozzle. The foam component dispensed from the nozzle expands when applied to a substrate, filling gaps and providing insulation.

The specification of a wall foam insulation machine varies according to the type and what it is designed to do. However, here are some common specifications with their meanings related to insulation wall foam machines.

Like any other machine, the wall foam insulation machine requires maintenance and care to ensure it performs well, produces great foam, lasts a long time, and avoids any preventable breakdowns. One part of taking care of the machine is regularly inspecting it to see if something is out of place or needs attention. Users should ensure that all parts and components of the machine are inspected, looked at closely, and checked to see if they need to be cleaned, adjusted, lubricated, or even replaced. The spray tips should be cleaned after every use. This prevents component blockage, ensuring consistent and reliable spraying performance. Apart from cleaning the tips, gently running clean, compressed air through them can also help avoid tip clogging.

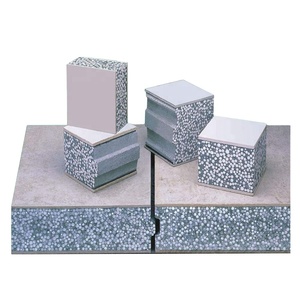

Due to their capacity to produce insulating foam in situ, wall foam insulation machines have a wide range of applications in the construction sector. The following are some typical applications:

Demand Analysis:

To align the business goals and target audience, it is crucial to determine the needs and requirements. It includes deciding on the types of foam insulation materials, the scale of production, and any particular features or capacities.

Machine Types:

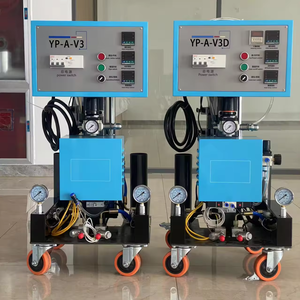

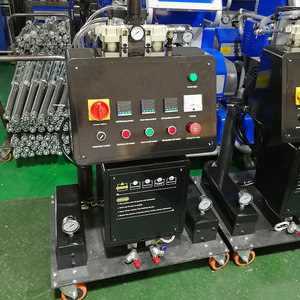

There are distinct advantages to each kind of wall foam insulation manufacturing device. Choose the ideal wall foam insulation machine for sale for the insulation material and target market, such as continuous, batch, or movable.

Machine Configuration:

Key components of wall foam insulation machines affect performance and reliability, such as the mixing system, spraying system, heating system, and control system. Select machines equipped with efficient, high-quality parts to ensure smooth operation and foam consistency.

Capacity:

Depending on business operations, the production capacity of wall foam insulation machines should match business needs. Consider the maximum production volume, stability at full load, and availability of extra components.

Energy Efficiency:

As energy costs are a major operational expense, choose machines with efficient power usage. This will help lower energy consumption and provide a return on investment.

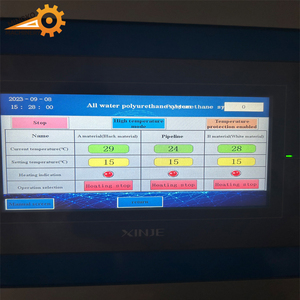

Automation and Control:

Consider the automation and control of wall foam insulation machines. Features like computer control, touch screen operation, and automatic monitoring can simplify management and boost production efficiency.

Quality and Reliability:

Choosing a reliable manufacturer provides long-term support and services. Foam wall insulation machine reviews are a good place to start. Consider the machine's quality and durability, which directly impacts company operations and maintenance costs.

Q1: Can buyers get a custom wall foam insulation machine design?

A1: Most manufacturers can design a custom wall foam insulation machine based on the buyer's specifications. But to ensure the customization is successful, buyers should partner with manufacturers with adequate experience and good quality equipment.

Q2: What type of foam insulator is the most efficient?

A2: Closed-cell foam insulation is more effective than open-cell insulators when it comes to resisting heat flow. This is because the cells within the foam are closed-off, tightly packed, and liquid-derived, which makes them more rigid. This rigidity improves the material's ability to insulate and resist heat transfer.

Q3: Can the insulation machine handle multiple materials simultaneously?

A3: Some multifunctional wall foam insulation machines can handle different types of insulation material. However, the machine's capacity to handle various materials will depend on its design and specifications. As a result, it's important for buyers to check the manufacturer's product details or ask directly if the machine can handle multiple materials.

Q4: What is the average size of a foam insulation machine?

A4: Manufacturers produce wall foam insulation machines in different sizes. But the most common dimensions are 48" (W) x 72" (L) x 60" (H). This machine has one mixing head and can produce up to 20 cubic meters of foam per hour. The size makes it easy for the machine to fit inside a standard wall.