(15 products available)

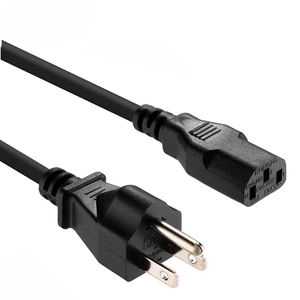

The UL-817 cord is available in different types. They include:

Coiled Cords

Often, coiled cords remain under tension and return to their original shape. Also, they maintain a compact form. Usually, the cord length expands during use, enabling mobility.

Flat Cords

These cords are fabricated with parallel conductors and a flat profile. Usually, they are ideal for applications with minimal space. Also, these Cords are commonly used in plug-and-play appliances and devices.

Spiral Cords

Similar to coiled cords, these are convoluted to allow for extension and return to the original shape. Often, the design is tighter and primarily for handheld devices. Therefore, they offer a shorter reach.

Heavy-Duty Cords

Conventionally, heavy-duty Cords are built with thicker insulation and more robust conductors. Therefore, they are suitable for high-power applications. These include industrial equipment and commercial usage.

Shielded Cords

Commonly, these cords contain an additional layer of insulation or a metal shield around the conductors. This reduces electromagnetic interference (EMI). Also, it enhances signal integrity. Normally, they are used in sensitive electronic devices.

The cord features diverse characteristics. They include:

Durable Materials

Conventionally, UL-817 cords utilize high-quality rubber or thermoplastic elastomer (TPE) materials. These are responsible for flexibility and durability. Standardly, these materials are retardant to abrasion, oil, and weather. Therefore, they are suitable for both indoor and outdoor applications.

Resistance to Heat and Cold

Normally, these cords maintain optimal performance in extreme temperatures. This is from -40°F to 140°F. Also, their insulated conductors are designed to resist heat generation. Thus preventing overheating in high-energy situations.

Multiple Conductor Options

Typically, UL-817 cords are available with two to five conductors. This accommodates varying power and signal needs. Also, more conductors enable complex systems to operate seamlessly.

Strain Relief Design

Customarily, a strain relief feature is integrated at connection points. This minimizes wear and tear on the cord. Therefore, it extends the lifespan of the electrical equipment in heavy usage scenarios.

Water and Dust Protection

Often, many UL-817 cords are designed with IP66 or higher ratings. In addition, they protect against water and dust ingress. Hence ensuring reliable performance in harsh environmental conditions.

Easy Installation

UL-817 cords are designed with straightforward plug connections. This ensures easy installation and replacement. Commonly, this feature saves time and reduces labor costs in commercial settings.

UL-817 insulating cords are applied in numerous commercial settings. Below is a list:

Event Venues and Theaters

Usually, The UL-817 cords are extensively used in theaters, concert halls, and event spaces. In these settings, they are regularly employed for stage lighting, sound systems, and video equipment. Also, their durability and flexibility make them ideal for environments where quick setup and breakdown are essential.

Broadcasting and Media Production

Typically, these cords offer reliability in transmitting power and signals between cameras, mics, and other production equipment. Further, in such dynamic settings, the cords ensure uninterrupted service even in high-demand scenarios.

Manufacturingand Industrial Settings

Often, the cords are used to connect machinery and equipment, especially where mobility is needed. They can power tools and machines across large workspaces due to their robust design. Therefore, enhancing efficiency and safety.

Commercial Kitchen and Foodservice Equipment

Habitually, in commercial kitchens, the cords power heavy-duty kitchen equipment. These include ovens, mixers, and dishwashers. Standardly, their resistance to heat and moisture makes them ideal for use in demanding food preparation environments.

Healthcare Facilities

Normally, they are instrumental in powering medical devices and equipment. Therefore, ensuring that critical care equipment is always operational.

When purchasing UL-817 electrical cords for other businesses, buyers should consider several factors. Here are some of them:

Usage

Buyers should get cords that suit their clients' needs. For instance, if their customers intend to use the cords indoors, they should get indoor extension cords. On the other hand, if the cords are intended to be used outdoors, they should get heavy-duty outdoor cords that are insulated to prevent weather elements, such as moisture and heat.

Length

Cord length refers to the distance between a plug and a power outlet. Buyers should get cords in various lengths so that they can cater to different consumers' preferences. Ideally, the cords' length should be proportional to the consumers' space requirements.

Customization

If business owners are seeking to place bulk orders for UL-817 cords that can be personalized, they should carry out research and settle for manufacturers who can provide such service. Moreover, they should look for suppliers who can offer them the cords in various colors so that they can suit different consumers' preferences.

Thickness

Electrical cord gauge thickness can affect the performance and safety level of an electric appliance. Therefore, it is important for buyers to understand the thickness of the UL-817 cords they intend to purchase. In this case, the lower the cord number gauge, the greater the electrical current it can convey safely.

Material

The UL-817 cord is manufactured using diverse materials. Each has its own advantage. For instance, plastic cords are advantageous because of their flexibility and light weight, while rubber cords are preferred for their flexibility and durability in harsh weather conditions.

The difference materials of the UL-817 cords make them ideal for specific applications. For instance, rubber cords provide flexibility and durability in harsh weather conditions. At the same time, thermoplastic elastomer cords remain robust over a wider temperature range and provide better insulation against electric shock.

UL-817 cords are manufactured using different materials, such as rubber and plastic. Each of these materials can be slightly modified in color. However, they are not usually available in many colors.

Yes, the UL-817 cords are suitable for daily heavy-duty professional uses. They are typically applied in settings like theaters, industrial areas, and broadcasting companies. These places require durable, flexible cords that can transmit power and signals effectively.

The cords have to be routinely inspected for wear, especially in high-usage areas. Also, after use, they should be cleaned to eliminate dust or moisture. In addition, they should be stored properly to avoid tangling or unnecessary strain when not in use.