(670 products available)

Thin vinyl sheets are versatile materials used in various industries, including construction, healthcare, and automotive, for their durability, water resistance, and ease of maintenance. They come in different types, each designed to suit specific applications and environments. Here are some common types of thin vinyl sheets:

1. Textured Vinyl Sheets

These sheets have embossed surfaces that mimic the look and feel of natural materials like wood, stone, or fabric. They add aesthetic value and provide slip resistance, making them ideal for flooring in residential and commercial spaces.

2. Decorative Vinyl Sheets

Thin sheets come in various patterns, colors, and prints, including floral, geometric, and contemporary designs. They are widely used in wall coverings, furniture, and cabinetry, allowing customization and interior aesthetics.

3. Acoustic Vinyl Sheets

These are specially designed to reduce noise and sound transmission. They have a dense and porous structure that absorbs sound waves, making them suitable for applications where noise reduction is crucial, such as in offices, hospitals, and schools.

4. Anti-bacterial Vinyl Sheets

These sheets are treated with anti-bacterial agents that inhibit the growth of bacteria and other pathogens. They are commonly used in healthcare settings, such as hospitals and clinics, where maintaining a sterile environment is critical.

5. Fire-retardant Vinyl Sheets

These are manufactured with materials that meet fire safety standards by slowing down flame spread or reducing smoke emissions. They are used in applications where fire safety is a concern, such as in public buildings and transportation.

6. Embossed Vinyl Sheets

These sheets have raised designs or patterns, adding tactile elements and visual interest to surfaces. The embossing can be subtle or pronounced, creating textures that enhance grip or decorative appeal.

7. Rigid Vinyl Sheets

These are sturdy and can withstand impact, making them suitable for applications requiring durability and strength, such as in construction materials, furniture, and signage.

8. Luminous Vinyl Sheets

These sheets absorb and store light energy, allowing them to glow in the dark. They are used for safety markings, signage, and decorative elements in low-light or dark environments.

Thickness and Size

Thin vinyl sheets come in different sizes and levels of thickness. Their thickness is usually measured in mils (1 mil equals 1/1000 of an inch). Commonly, the thickness ranges from 3 to 10 mils. The sheets also vary in size from 12 inches by 12 inches up to 60 inches by 120 inches.

Printing Quality

Thin vinyl sheets have excellent printing quality. They have high resolution and can be printed in vivid colors that are consistent. This makes them perfect for displaying business logos, promotional signs, and graphics.

Adhesive Backing

Some vinyl sheets have a pre-applied adhesive layer. This makes it easy to stick the surface to the intended application without the need for additional glue. The strength of the adhesive can vary, making it removable or permanent.

Finishes

Vinyl sheets come with different surface finishes, such as matte, texture, satin, and gloss. Each type of finish has its own aesthetic appeal and offers various levels of durability and protection against UV rays.

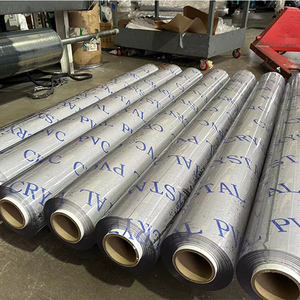

Material Composition

Thin vinyl sheets are manufactured using different grades of PVC (polyvinyl chloride). Each grade has its own level of durability, flexibility, and resistance to environmental factors.

Application

Thin vinyl sheets are suitable for various uses, such as signage, decals, graphics, and surface wrapping.

Maintaining thin vinyl surfaces is essential to preserving their appearance and prolonging their lifespan. Here are some general guidelines for maintaining thin vinyl surfaces:

Regular Cleaning

Thin vinyl surfaces should be cleaned regularly to avoid dirt and dust build-up. Use a soft cloth or sponge with mild soap and water. Carry out rinsing thoroughly to remove any soap residue. Avoid abrasive cleaners or materials that may ruin the surface.

Avoid Harsh Chemicals

Avoid using harsh chemicals when cleaning thin vinyl surfaces. Chemicals such as bleach, acetone, or ammonia can damage the material and cause discoloration.

Protect from Direct Sunlight

Avoid exposing thin vinyl surfaces to direct sunlight for a long time. Prolonged sunlight exposure can lead to fading and damage the material over time. Use protective window films or coverings to reduce UV exposure.

Avoid Sharp Objects

Avoid using sharp objects on thin vinyl surfaces. Scratches or cuts can cause permanent damage and reduce their aesthetic appeal.

Periodic Inspection

Carry out regular inspections of the vinyl surfaces to identify any signs of damage, such as peeling or fading. Address any issues promptly to avoid further damage.

Refrain from Using High Heat

Avoid exposing thin vinyl surfaces to high temperatures or direct heat sources. High temperatures can make the material to warp or crack.

With various options available, choosing the right thin vinyl sheets for any project can be challenging. Here are some key factors to consider when selecting thin vinyl sheets:

Purpose

Firstly, what is the intended use of the vinyl sheet? Is it for wall coverings, table protection, outdoor use, or vehicle graphics? The purpose will determine the type, thickness, and finish of the vinyl sheet needed.

Durability

Consider the durability of the vinyl sheets. For high-traffic areas or outdoor use, opt for more robust and tear-resistant sheets. The durability will affect the longevity and cost-effectiveness of the sheets.

Design and aesthetics

Choose a design or pattern that complements the existing decor or branding. Consider the color, texture, and finish (matte, glossy, or textured) of the sheets to ensure they align with the project’s aesthetic vision.

Installation

Consider the ease of installation. Some vinyl sheets come with adhesive backing, making them convenient for quick and DIY installations. Others may require additional adhesives or professional installation. Choose sheets that match the desired installation method and expertise available.

Maintenance and cleaning

For any thin vinyl sheet, the key is to use a soft brush and a mild detergent. Avoid harsh chemicals or abrasive cleaners, as they can damage the surface. Regularly wipe off spills and stains promptly to prevent them from setting. Periodically, do a deep clean by using a mixture of vinegar and water. It helps remove grime and bacteria buildup. Additionally, avoid using sharp objects near the sheets to prevent cuts and punctures. Keep the sheets away from excessive heat, moisture, or direct sunlight, as these can cause fading, warping, or peeling over time. Regularly inspect the sheets for any signs of damage, such as tears, bubbles, or discoloration. Promptly address any issues to prevent further deterioration.

Budget

Thin vinyl sheets are available in various qualities and prices. Set a budget beforehand and compare options within that range. Remember, more expensive sheets may offer better quality and durability, providing long-term savings.

Applying vinyl sheet flooring is simple and can be done as long as one follows the instructions keenly. Here is a step-by-step guide on how to install thin vinyl sheets:

Prepare the surface

Clean the floor and remove any debris, dust, old glue residues, and dirt. Also, take out the floor moldings and baseboards and ensure the subfloor is dry and clean.

Prepare the vinyl

Allow the vinyl to settle and reach room temperature for about 12 hours before installation. Cut the vinyl sheets to the desired size, allowing for edges and walls.

Apply adhesive

Spread the adhesive on the subfloor, starting with one section at a time. Use a notched trowel to enable even application and ensure the adhesive coats the full sheet's back.

Lay the vinyl sheets

Start in the center or a corner and lay the vinyl sheets carefully into the adhesive. Smoothen out any air bubbles or wrinkles using a vinyl flooring roller or a stiff brush. Move from the center to the edges to ensure even pressure and sheet adherence.

Trim and fit

Use a utility knife to trim the edges and ensure a perfect fit around corners, obstacles, and walls. For rounded corners and complex shapes, use a coping saw to cut the vinyl sheets.

Seam treatment

Treat any seams or joints between the sheets using a seam adhesive or heat sealer. This will help prevent water from getting into the floor and enhance the vinyl's durability.

Reinstall moldings and baseboards

Once the vinyl sheets are installed and the adhesive has dried, reinstall the floor moldings and baseboards. Use finishing nails or adhesive to attach them securely.

Clean and protect

After completing the installation of thin vinyl sheets, clean the surface and remove any excess adhesive. Allow the sheets to cure before moving furniture or walking on the floor.

Q1: What are thin vinyl sheets used for?

A1: Businesses commonly use thin vinyl sheets for signage, branding, vehicle wraps, and promotional materials. They are suitable for any project that requires a durable, weather-resistant surface with a printed design.

Q2: How long do thin vinyl sheets last?

A2: The lifespan of thin vinyl sheets depends on various factors, such as their intended use (indoor or outdoor), environmental conditions, and exposure to sunlight. Outdoor signage should be replaced every five years, while indoor signage can last until it is damaged or needs to be replaced.

Q3: Are vinyl sheets suitable for waterproofing?

A3: Vinyl sheets are water-resistant and can protect surfaces from water damage. However, if the project requires a waterproof material, consider a thicker vinyl sheet or other suitable materials.

Q4: Can vinyl sheets be printed on?

A4: Yes, businesses can print on vinyl sheets using various printing methods, such as digital printing, screen printing, and eco-solvent printing. Contact a professional printing service to get customized thin vinyl sheets.