Introduction to TEM Controllers

In today’s technologically advanced world, the TEM controller plays a pivotal role in various industries, particularly in thermal management systems. TEM, or Thermoelectric Module, controllers are essential devices for regulating temperature through precise electronic control. They are predominantly used in applications that require active temperature control, high reliability, and energy efficiency. Whether you are involved in industrial refrigeration, medical equipment temperature control, or environmental chamber functions, understanding TEM controllers can significantly enhance your operational capabilities.

Types of TEM Controllers

TEM controllers come in various types, each designed for specific applications and functionalities. Here are a few common types:

- Basic Controllers:

- Designed for simple on/off control of TEMs.

- Cost-effective solutions ideal for basic applications.

- PID Controllers:

- Utilizes Proportional-Integral-Derivative algorithms for temperature accuracy.

- Provides continuous adjustments, enhancing system stability and minimizing fluctuations.

- Smart Controllers:

- Incorporates IoT and machine learning for predictive adjustments.

- Enables remote monitoring and management for enhanced operational control.

- Digital Controllers:

- Features user-friendly interfaces with LCD screens for easy temperature readouts.

- Offers advanced programming options for complex temperature profiles.

Applications of TEM Controllers

The versatility of TEM controllers enables their use across a multitude of applications, making them indispensable in several sectors. Here are key applications:

- Medical Equipment:

- Regulation of temperature-sensitive devices and pharmaceuticals.

- Essential in maintaining stable environments in laboratories and clinical settings.

- Industrial Refrigeration:

- Used for precise temperature control in food preservation and processing.

- Important in sustaining the quality and safety of refrigerated goods.

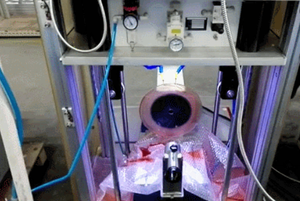

- Environmental Chambers:

- Provides accurate climate control for research and testing.

- Facilitates temperature variations for horticulture or material testing.

- Consumer Electronics:

- Regulates temperatures in high-performance electronics such as GPUs.

- Enhances device lifespan by preventing overheating.

Advantages of Using TEM Controllers

Implementing TEM controllers in your systems offers numerous benefits that can improve efficiency and performance:

- Enhanced Temperature Control:

- Maintains desired temperature settings with precision.

- Minimizes temperature variations for better product consistency.

- Energy Efficiency:

- Reduces energy consumption by optimizing cooling and heating processes.

- Contributes to lower operational costs in the long run.

- Increased Reliability:

- Designed for durability and stability over extended periods.

- Adequate fail-safes to ensure continued operation even during malfunctions.

- User-Friendly Interfaces:

- Modern controllers feature intuitive controls for easy setup and monitoring.

- Access to customization options allows users to tailor systems to their needs.