(3150 products available)

The T3 turbo refers to a turbocharger system commonly used in the automotive industry to enhance the performance and efficiency of internal combustion engines. There are various types of T3 turbos, as discussed below:

Single-Turbo T3 Turbo:

This is the most common T3 turbo type. It incorporates a single turbocharger into the exhaust system. The T3 turbo manifold links the turbocharger to the engine's exhaust system, enabling the utilization of exhaust gases to spin the turbine blades within the turbo, consequently compressing the incoming air to the engine and boosting its overall power.

Twin-Turbo T3 Turbo:

Twin-turbo T3 turbos utilize two turbochargers in the exhaust system. In most cases, T3 twin-turbochargers can be configured in either parallel or sequential arrangements. In parallel configurations, each turbocharger is connected to its own cylinder bank in V6 or V8 engines, whereas, in sequential configurations, a smaller low-pressure turbo is linked to the low-speed exhaust, and a larger high-pressure turbo is linked to the high-speed exhaust in a 6-cylinder or inline 6 engine configuration.

Variable Geometry Turbocharger (VGT):

This type of T3 turbo is designed to optimize the airflow through the turbine for enhanced efficiency and performance across a wider operational range. In VGT T3 turbos, adjustable blades within the turbine allow for changes in the angle of attack to suit various engine speeds. As a result, this optimizes boost pressure, minimizing turbo lag and maximizing boost at higher engine speeds.

Electric Turbo Compresso (ETC):

T3 electric turbo compresso utilize electric motors to drive compressors, thereby increasing the intake air pressure and eliminating lag. The electric motors within the ETC instantly spin up the compressors, generating boost before the engine reaches the turbo's effective RPM range. As a result, this significantly improves throttle response and ensures a consistent boost throughout the engine's entire RPM range.

Twin-scroll Turbocharger:

This type of T3 turbo is designed to improve efficiency and reduce turbo lag by utilizing two separate scrolls within the turbine. The twin-scroll design separates the exhaust pulses from paired cylinders, allowing for better energy utilization and reduced interference between the exhaust pulses. This ultimately leads to quicker spool times and increased boost efficiency.

The T3 turbochargers are an important part of the T3 turbos. They are the ones that compress the air going into the engine so that it can rev harder and faster.

T3 Turbo Specifications

The specifications of the T3 turbochargers are as follows.

1. Size: The T3 turbo size means how big the turbine wheel and the compressor wheel are. It affects how much power the turbo can make and how fast it will spool up. A bigger T3 turbo will take longer to spool up, but it will give more power at higher RPMs. The T3 turbo sizes are split according to the T3 turbo manifold measurements. The exhaust side of the turbo must match the T3 turbo flange. The most common T3 turbo sizes are 60mm to 70mm.

2. Bearing: The T3 turbo bearings support the shaft in the turbo. It is up to the type of oiling the bearings require that determines how long the T3 turbo will last. The T3 turbo bearings also affect how quickly the turbo spools up. The most common T3 turbo bearings are journal bearings and ball bearings. Ball bearings are better than journal bearings, even if they are more expensive.

3. Trim: The T3 turbo trim refers to how the compressor wheel and turbine wheel are shaped. The trim affects how much air the turbo can move and how it behaves. Higher aspect ratio trim numbers mean the turbo can compress more air, but it will take longer to spool. Lower aspect ratio trim numbers will give boost faster, but it will be harder to sustain a high boost level.

T3 Turbo maintenance requirements are as important as its specifications.

T3 Turbo Maintenance

1. Oil Changes: Oil changes are important for T3 turbo maintenance. The oil prevents the turbo from burning out due to friction. The oil also cools the turbo. By changing the oil regularly, the turbo will last longer. The oil change intervals should be followed depending on the vehicle's make. The intervals are usually between 3,000 to 5,000 miles. The oil filter must also be changed together with the oil to keep the turbo running smoothly.

2. Cool Down: Before switching off the car, it is important to let the T3 turbo cool down. This is because the engine run for a while heats up the turbo to very high temperatures. Turning off the ignition immediately can damage the turbo. The high heat remains trapped in the turbo and can cause the oil to leak. The oil will also burn quickly due to the high heat, and it will not lubricate the turbo as it should. Waiting for 2 to 3 minutes after turning off the car will give the turbo time to cool down properly.

3. Air Filter: The air filter must be checked and changed regularly for proper T3 turbo maintenance. The T3 turbo uses a lot of air for its operation. A clogged air filter will restrict airflow and cause the turbo to work harder. This will reduce how well the turbo performs and can damage it over time. The air filter should be checked every 10,000 miles. If it is dirty, it should be replaced. Even if the air filter is not yet dirty, it should be changed once every 30,000 miles.

Choosing the right T3 turbo for a specific vehicle or performance goal requires careful consideration of several factors.

Performance Goals

Determine the desired performance level, such as increased fuel efficiency or higher power output. Establish whether the primary goal is to enhance torque, overall horsepower, or both.

Engine Specifications

Take into account the engine's size, type, and current performance metrics. Consider aspects like the engine's displacement, its design (for instance, inline, V-shaped, or flat), and the fuel it uses (gasoline, diesel, or alternative fuels). Acknowledging these specifications guarantees that the chosen turbo aligns well with the engine's characteristics and capabilities.

Power Requirements

Estimate the power output in horsepower or kilowatts that is desired from the turbocharged engine. A more robust engine may necessitate a larger turbocharger, while a smaller engine may benefit from a more compact unit for quicker spool times.

Torque vs. Horsepower

Consider the balance between torque and horsepower. Turbos can be tuned to emphasize one aspect over the other. Higher torque is beneficial for tasks like towing or off-road driving, while increased horsepower is advantageous for high-speed performance.

Spool Time

Evaluate the importance of quick spool time versus sustained boost at higher RPMs. If rapid throttle response is crucial, a smaller turbo with a quicker spool time may be more suitable.

Application and Use

Consider the intended use of the vehicle. Is it for daily commuting, track racing, off-road adventures, or towing heavy loads? Different applications may require distinct turbo characteristics.

Environmental Considerations

Take into account emissions regulations and noise limitations. Some areas have strict emissions standards that need compliance, even with aftermarket parts. If noise is a concern, look for turbos designed for quieter operation.

Budget and Cost

Establish a budget for the turbocharger and any related components, such as intercoolers, exhaust systems, and engine management. Consider the long-term costs, including potential increases in fuel consumption and maintenance needs. Higher-priced turbos often deliver superior performance and durability, but it's essential to find a balance between cost and value.

Replacing the T3 turbo isn't a straightforward task. It requires a good understanding of auto mechanics, the right tools, and plenty of time. Here are the steps:

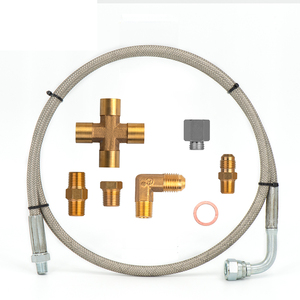

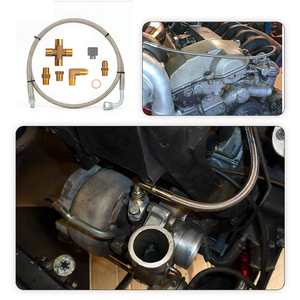

Gather the necessary tools: One would need a socket set, wrenches, screwdrivers, a torque wrench, an oil catch pan, and possibly a few specialized tools depending on the vehicle. A t3 turbo upgrade kit is also necessary.

Start by disconnecting the battery for safety. Then, drain the engine oil and coolant. Next, remove any components blocking access to the turbo, which could be the intake piping, exhaust piping, and possibly the downpipe. Depending on the vehicle's design, one may also need to remove the heat shield.

Locate the turbo mounting bolts and remove them. The T3 turbo is usually bolted to the exhaust manifold with a few dozen bolts. Remove the oil and coolant lines connected to the turbo. Be careful as some oil will leak, so have an oil catch pan ready.

Now, lift the turbocharger and undo the bolts holding it to the exhaust manifold. This part may require a little more time and effort, as the turbo is usually located deep in the engine bay. It's also a little tricky to remove the bolts due to their tight space.

Once the old turbo is removed, it's time to install the new T3 turbo. Grab the t3 turbo manifold and bolt it onto the exhaust. Then, attach the T3 turbo itself to the manifold. This is the reverse of the disassembly process. Make sure to tighten all bolts to avoid any leaks and ensure the oil and coolant lines are reconnected.

Reassemble any components that were removed to gain access to the turbo. This includes the downpipe, heat shield, intake piping, and anything else. Refill the engine oil and coolant. Reconnect the battery, start the engine, and check for any leaks or unusual noises. It may take a few test drives for the turbo to break in and for the car to feel different.

For those who aren't comfortable working on their vehicles' engines, it's best to seek a professional's help. While DIY may save costs, any slight mistake may lead to costly damages.

Q1: What does T3 mean in turbo?

A1: T3 refers to a type of turbocharger often used in high-performance vehicles. It's a design standard defined by the size and shape of the turbine and compressor wheels and the housings that contain them. T3 turbochargers are larger than T2 and smaller than T4, making them suitable for various engines.

Q2: Is the T3 turbo good?

A2: The T3 turbo is appropriate for many applications, particularly those requiring more power. The T3 turbo is a good option if the aim is to enhance the vehicle's performance without going overboard.

Q3: What vehicles can use the T3 turbo?

A3: The T3 turbo is commonly used in various vehicles, especially those requiring high-performance engines. Examples include sports cars like the Ford Mustang, muscle cars like the Chevrolet Camaro, and trucks like the Ford F-150. However, specific usage can vary depending on the vehicle's make and model.

Q4: Can the T3 turbo be installed on any engine?

A4: In principle, the T3 turbo can be installed on any engine. However, modifications may be required to make it fit and function correctly. It is always good to consult a professional mechanic before deciding to install a T3 turbo.