Introduction to Steel Laminated Elastomeric Bearing

Steel laminated elastomeric bearings are pivotal components in modern civil engineering, specifically in bridge construction and structural applications. They are designed to accommodate movements and loads, while providing stability and flexibility. These bearings are composed of alternating layers of steel plates and elastomer, which work together to absorb vibrations and shear forces, ensuring the longevity and durability of structures.

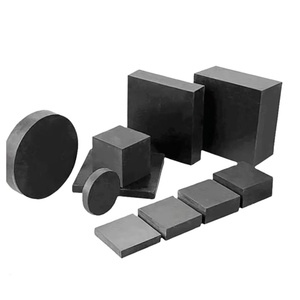

Types of Steel Laminated Elastomeric Bearings

There are several types of steel laminated elastomeric bearings, each tailored to meet specific engineering requirements:

- Plain Bearings: Basic configuration with no additional features, suitable for general applications.

- Neoprene Bearings: Made with neoprene elastomers, they offer excellent weather resistance and durability.

- High-Damping Bearings: Specifically designed to absorb dynamic loads and vibrations, ideal for seismic applications.

- Sliding Bearings: Incorporate a sliding layer to facilitate movement between structural elements, reducing friction and wear.

Applications of Steel Laminated Elastomeric Bearings

Steel laminated elastomeric bearings find extensive use across various engineering sectors, including:

- Bridges: Essential for load distribution and accommodating thermal expansion and contraction.

- Buildings: Used to support structures and enable movement in response to seismic activity.

- Industrial Structures: Effective for factories and warehouses where heavy machinery induces vibrations.

- Marine Applications: Employed in docks and offshore structures to manage wave forces and environmental movements.

Features and Advantages of Steel Laminated Elastomeric Bearings

The distinct features of steel laminated elastomeric bearings contribute significantly to their advantages:

- High Load Capacity: Designed to handle large loads effectively due to their robust construction.

- Vibration Isolation: The elastomeric component provides excellent damping characteristics, reducing structural vibrations.

- Resistance to Environmental Factors: High durability against moisture, UV rays, and temperature variations enhances longevity.

- Versatile Performance: Capable of accommodating various movements, including rotation, translation, and expansion.

- Maintenance-Free: Requires minimal maintenance throughout its lifespan, making it a cost-effective choice for engineers.