(7349 products available)

Types of stainless heat exchanger 300

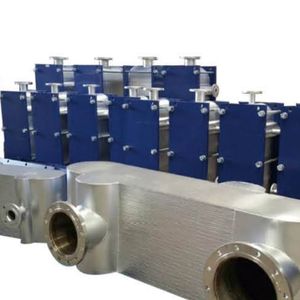

According to the configuration and working principles, the stainless heat exchanger can be divided into distinct types.

The specifications for industrial stainless steel heat exchangers will differ depending on the design type and application. Here are some typical heat exchanger specifications that will apply across different models.

Stainless heat exchanger maintenance is very easy, making these devices popular in industrial applications requiring regular upkeep. Manufacturers advise users to inspect the connections and plates of their heat exchers regularly. The goal is to ascertain whether there are any leaks that may have formed after use over time. If the user discovers any leaks, they should make adjustments immediately to avoid any safety threats.

The user should be on the lookout for any clogging, corrosion, or fouling signs within the heat exchanger. If any of these happens, they should undertake the proper cleaning and maintenance proceedeurs to maintain the efficiency of the exchanger. Monthly and periodic maintenance routines should be established so that components such as gaskets, pumps, and valves can be serviced and inspected. During the routine, the expert can advise the replacement of some components to enhance the performance of the heat exchanger.

It is very important that the installation manual and product instructions guides provided by the manufacturer during delivery are followed. Doing so ensures that the maintenance schedule and precautions required to keep the exchanger in excellent operating condition are well adhered to.

Food Processing and Dairy Industries:

Food and dairy industries use stainless steel heat exchangers to transfer heat between food or dairy products. For example, in a pasteurization process, a stainless steel heat exchanger cools down hot milk or juice until it reaches a safe temperature.

Chemical and Petrochemical Industries:

Chemical and petrochemical industries place stainless steel heat exchangers inside chemical reactors and other facilities where chemical reactions occur, traditionally to heat or cool chemical substances.

Power Generation:

Power plants use stainless steel heat exchangers in their turbines, condensers, and cooling towers to produce electricity. For instance, in a turbine, heat from steam turns the blades to rotate them, which actually generates electricity.

HVAC Systems:

Buildings use stainless steel heat exchangers to recover heat. For example, an HRXPR valve inside an air conditioner can cool down or heat up an entire room with recirculated air.

Oil and Gas Extraction:

Oil and gas drilling companies use stainless steel heat exchangers to cool down equipment and remove heat generated. For example, the catalyst inside a chemical reactor exchanges heat with a heat exchanger by a condenser, which allows chemical reactions and condenses the resulting gases, respectively.

When business buyers set out to purchase a stainless heat exchanger 300, certain factors need to be considered to ensure that they are going for the right piece. The first thing to consider is the working medium. Buyers should identify the mediums that need to be heated or cooled and the physical and chemical features of the mediums. Some common exchangers are made to withstand the pressure and temperature of particular working mediums. Thus, they are suitable for specific working mediums.

Next, buyers need to consider the temperature and pressure of the working medium. They must check the temperature and pressure of the medium during operating conditions. This includes the designed pressure, the high/low temperature limit, and the maximum allowable pressure. When buyers understand these factors, they will be able to choose an exchanger that has a design. The design will enable its performance within that pressure and temperature range.

Also, the intended use should be looked into. The heat exchanger is said to be suitable when it is fit for a piping system function, the required sealing performance, and the demanding heat transfer efficiency. If the heat exchanger will be used in industrial processes like oil refining, chemical production, or power generation, a plate heat exchanger would do. If used in HVAC systems, a tubular would be ideal.

Finally, the buyer should consider the environment where the heat exchanger will be installed, the connection method, and the available space. In this case, size and dimension become important.

Q1: What is the difference between a plate and frame stainless steel heat exchanger and a welded heat exchanger?

A1: A plate and frame stainless steel heat exchanger consists of thin plates that allow the flowing fluids to exchange heat. The stainless steel plate heat exchanger has a frame that holds the plates in place. In contrast, welded heat exchangers extensively use welds to hold the heat-transferring plates in place. Welded stainless steel heat exchangers can be used at higher pressure and temperature levels than the plate and frame design.

Q2: How long does an inox heat exchanger last?

A2: An inox heat exchanger can last for over ten years. Some factors impact its lifespan. The material construction will impact the expected lifespan. Stainless steel is known for its durability, so it is not unusual for some heat exchangers to last for 20 years. The operating conditions also impact the lifespan of an inox heat exchanger. If the heat exchanger operates normally, it could last for ten years or more. Frequent maintenance checks will help find small problem areas before they develop into large issues that could shorten the heat exchanger's lifespan.

Q3: What are the signs it is time to replace the stainless steel heat exchanger?

A3: There are a couple of signs that indicate it is time to replace the heat exchanger. If there is any form of crack or tear on the heat exchanger that could lead to fluid leaks, it is best to replace the component. Another sign is a significant decline in equipment performance. If the equipment is not able to perform at its peak, it may be due to a deteriorating heat exchanger, and it is best to replace the part. Excessive presence of corrosion also deteriorates the performance of the heat exchanger. Manufacturers recommend a replacement or repair service to rectify the corroded areas.

Q4: What is the cost to repair or replace the stainless steel heat exchanger?

A4: According to industry experts, the average cost to replace a stainless steel heat exchanger is approximately $2,500 to $6,000. The price will vary depending on the make and model of the heat exchanger. Costs to repair will also vary depending on the areas of damages and the skills of the technician carrying out the repair. Simple repairs like cleaning or descaling can cost around $400 to $1,000.