(64 products available)

Ready to Ship

Ready to Ship

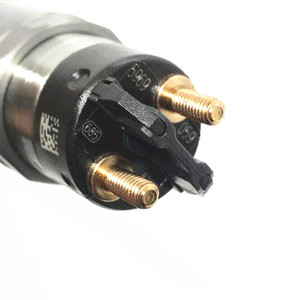

The SR20 fuel injector is a component of the engine's air and fuel management system that atomizes gasoline and delivers it into the combustion chambers. There are several types of SR20 fuel injectors, which include the following:

Port fuel injection

This is the most common type of fuel injector used in gasoline engines. It sprays a fine mist of fuel into the intake port just before the intake valve opens. This allows the fuel to mix with air as it enters the intake manifold, ensuring an even distribution of the fuel-air mixture to all engine cylinders. Port fuel injection helps improve throttle response, reduce emissions, and enhance overall engine performance.

Direct fuel injection

Direct fuel injection is a technology that injects fuel directly into the combustion chamber at high pressure. By allowing precise control of the fuel-air mixture and better atomization of the fuel, direct injection improves fuel efficiency and reduces emissions. It also enhances engine performance, especially at higher speeds and loads. Many modern gasoline engines use a combination of direct and port fuel injection to optimize performance, emissions, and fuel economy.

Multi-point fuel injection

Multi-point fuel injection (MPFI) is a fuel injection system that uses one fuel injector per engine cylinder. Each injector atomizes fuel into the intake air stream entering its respective cylinder. MPFI ensures better control of the fuel-air mixture for each cylinder, leading to improved engine performance, better fuel efficiency, and reduced exhaust emissions compared to older carburetor-based systems or single-point injection.

Sequential fuel injection

In a sequential fuel injection system, fuel injectors spray fuel into the intake manifold or directly into the combustion chamber in a precise sequence, matching the firing order of the engine's cylinders. This allows for better control of the air-fuel mixture and improves engine performance, emissions, and fuel efficiency, especially in multi-cylinder engines. While sequential fuel injection can be implemented with both multi-point and port fuel injection systems, it adds complexity and cost to the fuel injection system.

Fuel Injector O-Rings

Replacing the fuel injector O-rings is a simple task that can be done with basic mechanical skills. Start by relieving the fuel system pressure following the manufacturer's guidelines. Remove the fuel rail and carefully take out the injectors. Replace the O-rings on each injector, ensuring a proper fit. Reassemble the fuel rail and injector assembly and prime the fuel system before starting the engine.

Fuel Injector Bungs and Bushings

Upgrading to larger bungs and bushings may be necessary when increasing fuel injector size for performance gains. Consult with a professional engine builder to determine the appropriate dimensions for compatibility with the intake manifold and fuel rail. The installation process involves removing the old bungs from the intake manifold and installing the new ones. Ensure proper alignment and sealing to prevent air and fuel leaks.

Fuel Injector Cleaner

Using a fuel injector cleaner is a proactive maintenance step to keep injectors performing optimally. Choose a high-quality cleaner compatible with the vehicle's fuel system. Follow the instructions on the cleaner's packaging for the correct dosage and application method. Whether added to the fuel tank or prescribed through the fuel rail, the cleaner will help remove deposits and improve atomization.

Cleaning Fuel Injectors

Cleaning fuel injectors is a crucial maintenance task that ensures optimal engine performance and fuel efficiency. Over time, injectors can accumulate carbon deposits, leading to clogged nozzles and uneven fuel distribution. To clean them, a professional-grade fuel injector cleaning machine is used, which combines a cleaning solvent with pressurized fuel. This solvent flushes out impurities, restoring proper spray patterns. Additionally, using a fuel injector cleaner additive in the fuel tank helps prevent future build-up by keeping the injectors clean and lubricated.

Inspecting Fuel Lines and Connections

Regularly checking fuel lines and connections for leaks, wear, or damage is essential to maintaining a healthy fuel system. Cracked or deteriorated hoses can lead to fuel leaks, posing fire hazards and causing fuel wastage. Additionally, loose connections can result in injector malfunctions and rough engine performance. Visual inspections should be complemented by feeling the hoses for soft spots or swelling. Any issues found should be addressed immediately by replacing damaged hoses or tightening loose connections to ensure a safe and efficient fuel delivery system.

Monitoring Fuel Pressure

Monitoring fuel pressure is crucial to maintaining the fuel system's health. Fuel pressure gauges can be used to ensure the fuel pump delivers the correct pressure specified by the manufacturer. Inadequate fuel pressure can cause injector underfeeding, leading to lean air-fuel mixtures and potential engine damage. Conversely, excessive pressure can over-saturate the injectors, resulting in rich mixtures and poor combustion. DIY enthusiasts can easily install a fuel pressure gauge kit and follow the manufacturer's instructions for monitoring and troubleshooting fuel pressure issues.

Choosing the right SR20 fuel injector for a particular vehicle can be a daunting task. However, with the following tips, it will be much easier.

The primary step in choosing the right SR20 fuel injector is understanding the car's engine performance needs. For standard engine performance, a stock fuel injector will suffice. However, for modified engines that aim for higher horsepower, bigger fuel injectors will be required to provide adequate fuel supply.

It is also important to consider fuel injector flow rate when choosing an SR20 fuel injector. Flow rate is a crucial factor since it determines how much fuel the injector can deliver to the engine. Fuel injectors with a higher flow rate support more significant engine modifications and higher power output, while those with lower flow rates are suitable for stock engine performance. As a rule of thumb, choosing a fuel injector with a flow rate that meets or exceeds the engine's fuel requirements is advisable.

Moreover, understanding the injector spray pattern is important when choosing an SR20 fuel injector. Different fuel injectors have distinct spray patterns, such as cone or axial. The injector spray pattern should match the engine's combustion chamber design for optimal fuel atomization and efficient combustion. This ultimately translates to better engine performance and increased fuel efficiency.

Consider the fuel type the injector is designed to work with. Fuel injectors are designed for gasoline or ethanol-based fuels. Ensure the fuel injector is compatible with the type of fuel used in the vehicle. This guarantees optimal performance and prevents fuel system issues.

Compatibility is also a key factor to consider when choosing an SR20 fuel injector. While the fuel injector may be of great quality, it will be of no use if it is not compatible with the vehicle's fuel rail and electrical connector. Before purchasing, it is important to double-check that the fuel injector is compatible with the vehicle's make, model, and engine specifications.

Once the right fuel injector is chosen, it's important to have it installed by a professional mechanic. Proper installation is crucial for the fuel injector to function correctly and the engine to perform optimally. A professional mechanic also helps to make necessary adjustments to the engine's fuel mapping or calibration to accommodate the new fuel injector, ensuring the engine receives the right fuel mixture for optimal performance.

Replacing a fuel injector can be a daunting task, but with the right tools, knowledge, and determination, it can be done. The following is a simple guide on how to replace an SR20 fuel injector.

Q1: How can a malfunctioning fuel injector be identified?

A1: Signs of a bad fuel injector include reduced engine performance, increased fuel consumption, rough idling, emissions failure, and check engine light. Visual inspection, sound check, and performance tests can help identify injector issues.

Q2: Can fuel injectors be cleaned, and how is it done?

A2: Yes, fuel injectors can be cleaned. Injector cleaning machines, fuel system cleaners poured into the fuel tank, or direct applications into the intake manifold are methods used to remove deposits and restore flow.

Q3: What are the differences between fuel injectors for petrol and diesel engines?

A3: Petrol engines use lower pressure (30-50 psi) injectors that atomize fuel. Diesel engines use high pressure (1000+ psi) injectors that spray fuel. Diesel fuel is thicker and requires more energy to inject compared to petrol.

Q4: What is the expected lifespan of fuel injectors?

A4: Fuel injectors typically last 50,000 to 100,000 miles. Factors affecting lifespan include fuel quality, engine condition, and maintenance practices.

Q5: Can other engine performance issues be confused with fuel injector problems?

A5: Yes, symptoms like rough idling or poor acceleration can be caused by issues with spark plugs, air intake, or sensors. Fuel injector issues must be diagnosed alongside other potential causes.