(8085 products available)

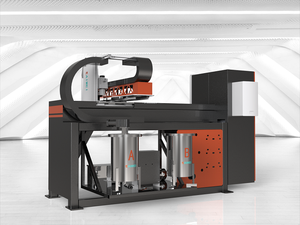

Spray foam insulation machines are pieces of equipment that are used to install spray foam insulation. It is a kind of insulation that goes through an air-tight seal against energy against pollutants. People transport the two parts of foam insulation (the wall and the pump) around the business site with the help of spray foam insulation machines.

Portable spray foam insulation machine:

Portable machines for spray foam insulation are more accessible than ever and can easily be taken anywhere in the world. They are also pretty easy to install, usually coming with a quick-connect system that gets the firearm attached to the proportioning unit in no time. These kinds of machines are those that contractors use for home guard work, attics, and crawl space sealing, insulation in the vicinity of doors and windows, water pipe insulation, and soundproofing, to name a few.

Diesel spray foam insulation machine:

For jobs that require high output and long hose lengths, as well as locations without electricity, the ideal option is the Diesel-powered spray foam insulation machine. One of its main features is that it is dual heated, which means that both sides of the foam are heated, helping to ensure better mixing and higher yields. It also comes proportioning systems that are air-driven, ideal for not using electric-based equipment in certain environments.

Electricity spray foam insulation machine:

For those areas in the home that are hard to reach, the electric spray foam insulation machine is here to help. This foam machine for spray insulation can work in areas that are up to 200 feet away from the machine. It does this by using heated hoses that carry the foam mix from the proportioning machine to the spray nozzle. It has a compact design that is easy to manoeuvre, allowing users to spray irregular shapes, tight spaces, and overhead areas efficiently. It can also save energy by using a hydraulic drive system that helps to reduce pump wear while energizing the system only when needed.

Some key specifications of spray foam insulation machines are as follows:

Regular maintenance of spray foam insulation equipment is also essential for consistent production and effective application. Some standard maintenance methods are as follows:

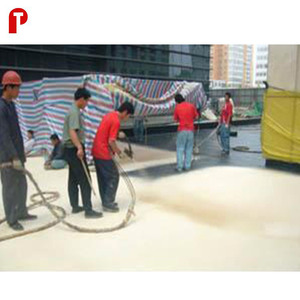

Construction and renovation businesses are significant buyers of spray foam insulation machines, as they need the equipment to apply insulation to newly constructed homes, commercial buildings, and offices or when reinvestment is required. They are looking for machines with varying capacities, from handheld units for small projects to high-output foaming machines for large-scale construction.

Contractors also buy spray foam insulation machines for weatherization projects to seal air leaks around doors, windows, and other penetrations in the building envelope. They need machines that are quick, efficient, and reliable to improve the energy efficiency of structures.

Another scenario in which contractors and insulation professionals buy spray foam machines is when the demand for insulation in the local market is high. For instance, this could happen when energy prices are high, prompting homeowners to look for ways to reduce energy consumption. Insulation is one of the most effective ways to reduce energy use.

Spray foam insulation machines are also used in marine applications to insulate boats and yachts. The insulation is lightweight, durable, and provides excellent thermal protection, keeping the interior of the vessel comfortable.

The refrigeration industry uses spray foam insulation machines to manufacture refrigerated containers, trucks, and boxes. Spray foam offers superior insulation performance in a lightweight material, helping to maintain temperature-controlled environments during transit or storage.

Some manufacturers produce spray foam insulation machines for the DIY market. These are smaller, more affordable machines designed for homeowners who want to undertake small insulation projects independently. Many DIY users choose open-cell spray foam due to its cost-effectiveness and ease of use.

Supermarkets and food production facilities use spray foam insulation to maintain temperature in cold storage areas, walk-in freezers, and refrigeration units. The foam can easily be applied in thick layers to minimize heat transfer and keep energy costs down.

There are many things to consider when buying a spray foam insulation machine for sale or looking for suitable spray foam insulation equipment suppliers to meet business needs. First of all, it is needed to strike a balance between machine performance features and customer preferences. Check if the machine is easy to use, quickly foam spray insulation, and clean and whether it is mobile or portable.

Secondly, it is important to consider the capacity and pressure of the foam sprayer machine. Because of the diverse applications of spray foam insulation, various sizes and capacities of the machine are available for selection. The production rate of the machine is closely related to the job completion time. Therefore, buyers need to choose a model with an appropriate capacity based on demand and project size. Customers often expect the spray foam insulation machine to work efficiently and complete the task within a tight schedule. In addition, the pressure control of the spraying nozzle can affect the coverage and density of foam insulation. So, buyers also need to consider project requirements and spray application techniques to select a machine with suitable pressure.

It is also important to consider the insulation material that the spray foam insulation spraying machine supports. Different machines may be compatible with distinct types of spray foam insulation materials, such as polyurethane, phenolic, or other formulations. Buyers need to choose a machine that can handle the insulation material according to their needs or the projects they serve.

Additionally, the training and technical support offered by the supplier should be considered. Some buyers may have limited experience with spray foam insulation machines or require assistance training their staff to operate the equipment safely and effectively. In this case, it is essential to select a supplier who provides comprehensive training programs and continuous technical support to ensure smooth machine operation and optimal spray foam insulation results.

Q1: Is it worth buying a spray foam insulation machine for small jobs?

A1: It is worth purchasing a foam spray insulation machine to undertake minor spray foam insulation projects. Portable machines are adequate for smaller projects. Buying an insulation machine for small jobs can save costs by eliminating the expense of hiring a contractor.

Q2: What qualities of a spray foam insulation machine should buyers look for?

A2: Buyers should look for the durability of the construction materials and the overall build quality of the insulation machine. Good storage capabilities, ergonomic designs, and efficient heating and mixing systems are also essential qualities to consider when buying a spray foam insulation machine.

Q3: What is the role of a spray foam insulation machine?

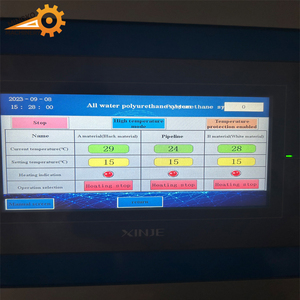

A3: A spray foam insulation machine provides the precise-controlled mixing and proportioning of spray foam insulation components. The control box of the insulation machine regulates the temperature and pressure of the foam components. It also ensures the correct foam formation by mixing the two chemicals at a high speed.

Q4: What types of spray foam insulation machines are available?

A4: There are two main categories of machines for spray foam insulation: trailers and boxes. Spray foam insulation machines in trailers suit large applications. They come with a built-in power source, heated hose, and foam rig. Generator-mounted or stored in a carrying case, box machines are more portable and ideal for smaller applications.