(490 products available)

PVC encapsulation is available in various types to cater to diverse needs. Each type offers unique benefits depending on the required level of protection, application, and environment.

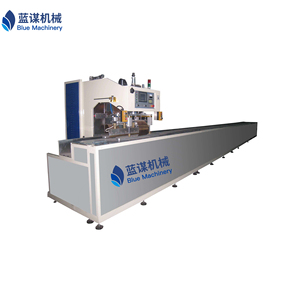

A mass production technique, automatic encapsulation uses specialized machinery to apply PVC in high-volume settings. This method ensures uniformity and speed, making it ideal for large-scale manufacturing. In industries where high demand necessitates quick output without sacrificing quality, automatic encapsulation is the preferred choice.

Manual encapsulation applies a PVC layer by hand and is often used for small-scale operations or specialized tasks. While labor-intensive, it allows for greater flexibility, particularly for custom jobs or where intricate detailing is required. In settings where personalization or small batch sizes are needed, manual encapsulation remains essential.

The semiautomatic encapsulation strikes a balance between the two methods by using partially automated processes that require some manual intervention. This method is efficient for mid-range production where demand does not justify full automation but still requires enhanced output compared to purely manual work. In industries experiencing fluctuating demand, semiautomatic systems can provide a viable middle ground.

Using heat for encapsulation, this method employs a specialized system that heat bonds flexible polyvinyl chloride (PVC) to product surfaces. Common in the automotive and electronics sectors, heat encapsulation ensures strong, durable seals resistant to extreme conditions. This technique is vital where longevity and performance essential.

This encapsulation method applies heat and chemical means to bond PVC to surfaces. Strong and rigid structures in automotive and aerospace industries favor this technique for its solid protections. High-stakes environments benefit from chemical encapsulation, offering security where even slight failures could have grave consequences.

PVC encapsulation provides several features of unparalleled advantages. These factors determine its function to enhance product durability through material density and increase resistance to various elements.

PVC encapsulation is prized for its protective qualities, significantly extending product life in harsh environments. The encapsulation forms a robust layer over components, shielding them from moisture, chemicals, and physical damage. This protective cocoon not only prevents wear and tear but also boosts the product's functionality over time, resulting in less frequent replacements and long-term cost savings for users. By fortifying items with encapsulation, industries can ensure that their investments endure for years to come.

How PVC encapsulation is applied and what shapes it takes can be easily modified to fit most client requirements. Colors, textures, and sizes are conveniently adjustable, meaning encapsulation packaging readily fits a broad scope of products, from electronics to automotive parts. Thanks to this flexibility, industries can easily develop unique protection solutions that accommodate their branding and functional requirements harmonizing with the nature of their respective businesses. With such flexibility, PVC encapsulation is perfect for numerous businesses with various needs.

The encapsulation keeps moisture and air from getting inside materials, leading to effective acoustic isolation. This feature is extremely helpful in audio or construction industries where sound control is very important. Because it dampens vibrations and lowers noise transmission, PVC encapsulation allows items to work more quietly and efficiently. Hence, this promotes an active environment in workplaces.

Encapsulation safeguards products and reduces the need for frequent repairs and replacements. The low application and maintenance costs make this a practical choice compared with other protective methods like coatings or enclosures. Thus, businesses of all sizes, including those needing high-volume production and those with smaller operations, will find this method very affordable. For every dollar spent on encapsulation, significant savings not only protect the investment but also ensure superior-quality encapsulated products.

Commonly, encapsulation of PVC is extensively employed to provide protection to materials and is sought after due to its flexibility and durability. It guards components from damage and prolongs their life while adding aesthetic value.

Plastic materials such as wires and circuit boards are insulated, protected, and made functional using PVC encapsulation in the electronics industry. It is critical to maintaining safety and dependability in electrical cables since it shields these components from moisture, pollutants, and physical contact. Protective packaging also makes electronics more amenable to shipping and storage.

In the automotive sector, PVC encapsulation protects electrical systems, wiring harnesses, and other components. It safeguards against moisture, chemicals, and extreme temperatures, which is vital for maintaining component integrity in challenging environments. Furthermore, PVC encapsulation is also used to coat car floor mats and is popular for integrated branding, providing color variety and a more sleek overall appearance.

Construction takes advantage of PVC encapsulation via protecting insulation materials and electrical wires, among other things. PVC plays a key role in preserving energy-efficient insulation from environmental degradation and encapsulating electrical wires. The encapsulated PVC house wrap prevents moisture, increases house durability, and wraps homes.

In the packaging industry, encapsulation is done using PVC to detach and encapsulate items like labels, cards, and various small goods. By fully encasing a product, encapsulation affords protection from wear, tarnishing, and environmental elements such as moisture and heat, ensuring items arrive intact and functional at their destination. This technique is sought in retail and promotional packaging for a polished appearance and durable enhancement of the product.

Industrial settings demand robust protections for tools and equipment, where PVC encapsulation comes into play. It guards machine parts, tools, and equipment components from rust, moisture, and abrasions, helping to minimize downtime and maintenance costs.

Selecting the proper PVC encapsulation for diverse applications requires careful deliberation. These entail aspects including performance, cost, and the environment where the encapsulated item will be deployed.

One key consideration when selecting PVC encapsulation is temperature resistance. PVC encapsulation products should have varying temperature tolerances, depending on whether they will be used in electronic components or outdoor construction. Choose encapsulation materials that can withstand the specified temperature range without loss of integrity or degradation to resist failure in extreme heat or cold.

Viscosity is an important factor in PVC encapsulation selection. A material's viscosity level is related to its processing and application; this means that low-viscosity materials may flow and fill molds easily, whereas high-viscosity substances offer thicker layers for improved protection. To choose appropriate encapsulation, consider the application demands to ensure that the viscosity level correlates with performance enhancement.

Consider the simplicity of using and applying PVC encapsulations when choosing. Manual encapsulation can be labor-demanding, while automatic encapsulations are easy and faster. Select the type of encapsulation that is compatible with the existing production processes to avoid future disruptions. In cases requiring heat or chemicals, it is prudent to note that these processes can add complexity and should only be considered when necessary. Finding encapsulation with simpler usage can significantly streamline operations.

Adhesion is critical in encapsulation since PVC should bond appropriately with surfaces to provide proper protection. Assess the encapsulation's capability to adhere to different substrates, such as metals, plastics, or electronic components, and ensure compatible materials exist. Adequate adhesion guarantees a solid barrier against environmental stresses within the product's life cycle and many encapsulated products.

The growing consciousness of environmental issues calls for a consideration of the ecological effect of selected encapsulation methods. Though PVC is a robust encapsulation material, its environmental implications, including recyclability and potential pollutants during usage, should be evaluated. Currently available alternatives can provide similar protections with less ecological impact. It's also possible to consider the green certifications of the products to fit sustainability policies.

A1: PVC encapsulation is widely used across many industries to protect electrical and electronic components such as automotive parts, and construction materials.

A2: PVC encapsulation durability, waterproofness, and versatility make it ideal for protecting electronics, automotive components, and insulated wiring in construction.

A3: While choosing PVC encapsulation, it is important to consider temperature resistance, adhesion, viscosity, and the environment in which it will be applied.

A4: The affordability, broad usability, and exceptional protection offered by PVC encapsulation have made it a popular choice across numerous industries.