(64594 products available)

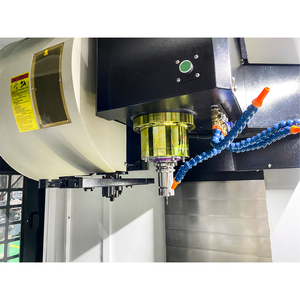

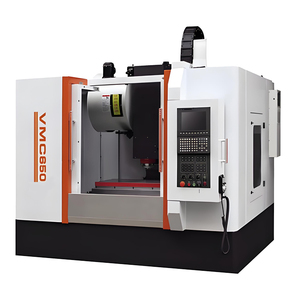

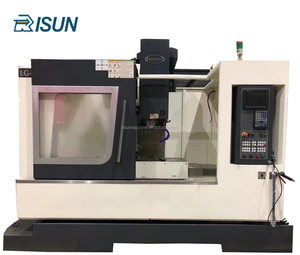

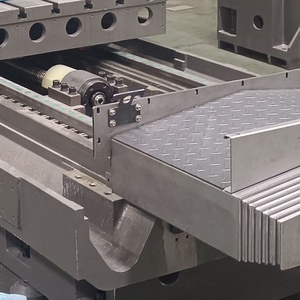

A processing center is a pivotal part of a machining system, featuring a specialized machine tool that can execute various processes, including milling, drilling, tapping, and countersinking. They can be fixed or portable, and there are usually two types of processing CNC centers:

The specifications of a meat processing center will vary depending on the type, model, and features. Generally, buyers can find key processing center specifications.

Machine dimension:

The overall length, height, and width of a meat processing machine are expressed in units like inches or feet. The meat processing machine dimension is crucial since it helps determine space requirements and installation.

Production capacity:

Processing centers have different food production capacities. Some can produce around 100 to 1,000 pounds of processed meat in a single hour. Larger industrial processing meat machines typically have higher production capacities than smaller ones.

Meat Processing Functions:

Meat processing centers usually process meat in more than one way. The centers can mince, grind, slice, strain, chop, mix, emulsify, cook, smoke, cool, freeze, and fill. However, each machine generally has some specific functions like grinding and mixing.

Types of Meat:

Meat processing machines are designed to handle different types of meat. Some processing meat machines handle red meat, fish, poultry, or a combination of the mentioned meats.

Power source:

Meat processing machines use electricity or gas. Gas-powered centers are more preferable in remote locations with limited access to electricity. On the other hand, an electric machine power voltage is specified in watts, usually ranging from 2,000 to 10,000.

Parts and accessories:

Meat processing machines come with essential parts like blades, choppers, strainers, mixers, filling tubes, and slicers. Each part has its own unique function. For example, the blades chop and mince the meat.

Maintaining a meat processing center is critical for efficient meat processing, food safety, machine performance, hygiene, and the longevity of the machine. Processing centers also require more than just maintenance. Regular cleaning, sanitization, and maintenance are crucial to ensuring the health and safety of workers and customers.

Meat processing machines mostly have straightforward cleaning instructions. Nonetheless, it is always important to refer to the specific meat processing machine manual instructions to ensure appropriate cleaning and avoid damage.

Usually, maintenance instructions include but are not limited to the following:

With the development of technology, the application scenarios of the wood center processing machine are expanding, and there is still a vast room for development.

At present, it is mainly used in the following industries and scenarios:

Selecting the right food processing center requires careful consideration of several factors. Firstly, quality assurance is paramount. Buyers should look for centers that adhere to international food processing standards and certifications, ensuring that the end products are safe for consumption.

The capacity and scalability of the processing center are also important. As businesses grow, they need partners who can accommodate increased production demands. Investigate the equipment and technologies available at the center to determine if they can handle larger volumes smoothly.

Additionally, the range of services offered by the processing center should align with specific business requirements. Some centers specialize in certain types of processing or have limited value-added services compared to others. Explore different options and find out what centers can provide exactly what was needed to enhance the supply chain.

Collaboration is key in selecting a processing partner. The chosen center must be willing to work closely with the business to customize products according to unique brand preferences. Good communication channels should also exist between both parties for transparency throughout the entire process.

Finally, logistics play an essential role in determining the ideal food processor. Consider factors such as storage facilities, distribution networks, and shipping arrangements provided by potential partners. These logistical capabilities directly impact efficiency and cost-effectiveness along the entire supply chain.

Q1: What is the difference between a CNC machining center and a CNC mill?

A1: The machining center has a tool magazine, allowing it to perform various tasks without operator intervention. It can also be equipped with more features than a CNC milling machine, such as being multi-axis and having more types of machining processes. In comparison, the CNC milling machine will mostly just cut and be a simpler mechanism.

Q2: What are the three types of machining centers that are commonly used?

A2: The FAQ answer is already in the article. The three types are horizontal machining centers, vertical machining centers, and gantry or rigid spindle machining centers.

Q3: What are some recent innovations in machining center technology?

A3: Some innovation includes the increase in spindle speed and tool change speed, as well as the addition of more advanced automatic tool changers and spindle technologies. Other advancements are the five-axis machining capability and the use of artificial intelligence for predictive maintenance.