(6976 products available)

A polyurethane foam machine makes insulation foam that provides thermal resistance in home and commercial buildings. Spray foam insulation has two main components: isocyanate and polyol blend, which are stored in separate tanks. When the materials mix, they react with each other, forming a gas that expands and makes the insulating foam.

The two main types of spray foam insulation made by a polyurethane foam sprayer are:

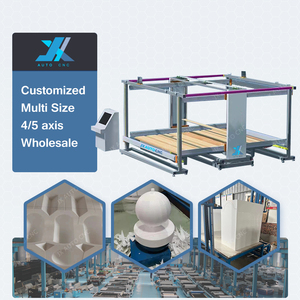

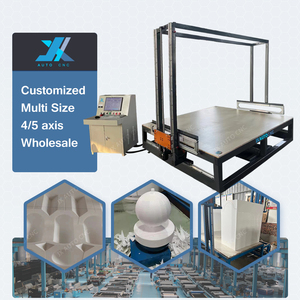

Besides the insulation types, there are different kinds of foam spray machines for sale on the market:

When purchasing a PU foam machine, buyers should consider the machine's specifications. Common polyurethane foam machine specifications include volume flow rate, mixing ratio, spraying distance, pressure, and power requirement.

Maintaining a PU foam spraying machine is crucial to keeping it in good shape and operating well. Some maintenance tips are as follows:

The application of the polyurethane foam machine price is quite diverse, especially in the construction, packaging, and automotive industries.

Construction Insulation:

In the construction industry, the insulation of roofs, walls, and floors is done using the polyurethane foam machine. This helps to control the indoor temperature by keeping the heat in during winter and the heat out during summer. Furthermore, the insulation provided through this machine also helps to cut down on energy bills and make the building more eco-friendly.

Packaging Protective:

Around delicate products, protective packaging is done using the polyurethane foam machine. This includes the cushioning of products like electronics, instruments, and glassware that can easily break. Through this protective packaging, the risk of damage is significantly reduced.

Automotive Interior:

In the automotive industry, the interior detailing is done using the polyurethane foam machine. This includes car seats, headliners, door panels, and dashboards. The soft-touch feel and comfort of the polyurethane foam machine helps absorb shocks from the road as well.

Cold Chain Logistics:

In the cold chain logistics industry, refrigeration containers are created through the polyurethane foam machine. This also includes refrigerated trucks and sea containers that help maintain a consistent temperature inside, no matter the weather outside.

With the help of a foam machine, products like food, pharmaceuticals, and chemicals are transported safely. The insulation also minimizes any product spoilage.

When selecting a suitable polyurethane foam machine for business, it's important to consider several key factors. First, it's essential to determine the required capacity and output of the machine based on specific needs and applications. Next, it's crucial to evaluate the quality and performance of the machine, ensuring it can produce high-quality foam consistently. The machine's features and technology also play a significant role in the decision-making process—efficiency and energy consumption of the machine to minimize operational costs. It's vital to consider the maintenance and service support available for the machine, ensuring it can be easily maintained and serviced when needed. Finally, the machine's compatibility with existing production lines and space requirements must be considered to ensure a smooth integration process. By carefully considering these factors, businesses can choose a suitable polyurethane foam machine that meets their requirements and contributes to their production line's success.

Q1: What factors influence the price of a polyurethane foam machine?

A1: The price of a rigid polyurethane foam machine or flexible varies due to some factors like the quality, type, and specification of the machine. More advanced machines with additional features like automatic control, data integration, and high-precision metering typically have higher prices. Larger capacity machines that handle more significant volumes of foam production are generally more expensive. The quality of the machine, including its durability and performance, impacts the price.

Q2: Are there affordable options for polyurethane foam machines?

A2: Yes, there are some affordable options for machines available. Choosing a simple model with basic features can save costs. Another option is to look for a used polyurethane foam machine for sale. Requesting a price quotation from different suppliers and comparing their offers is also recommended.

Q3: What is the price trend for polyurethane foam machines?

A3: The price of the machine rises steadily with the increasing demand for foams in various industries, especially in the automotive and construction industries. However, there might be fluctuations in the prices due to some factors like changes in raw material costs, economic conditions, and technological advancements.

Q4: What is the price range of polyurethane foam machines?

A4: The price of small foam machines start from hundreds to few thousands of dollars. Bigger and more advanced types like the high-pressure polyurethane foam machine cost thousands to tens of thousands of dollars.