(28944 products available)

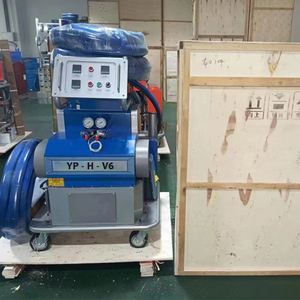

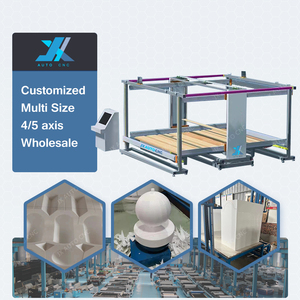

A polyurethane foam foaming machine is used to produce commercial-grade flexible, rigid, semi-rigid, and integral skin bulk foam or open-cell or closed-cell foam. Depending on the type of foam to be made, different types of foaming machines are used with distinct characteristics to ensure accuracy and precision. The foaming machines can have a low pressure or high-pressure design, and some integrate spray systems that allow on-site application of the material being sprayed.

Low-pressure foaming machines:

These machines are designed to produce foams with low processing pressures, such as flexible and integral skin foams. They use the latent heat of vaporization of liquids, surfactants, and water to produce foam. Low-pressure foaming machines mix the components of the foam in a blending head and then pump the mixture into a mold, where it expands and cures to form the final product. The machine typically has a propeller system to mix the components of the foam and a piston to extrude the foam mixture into the mold. The disadvantage of these machines is that operators could be exposed to isocyanates from the chemicals used in the machine.

High-pressure foaming machines:

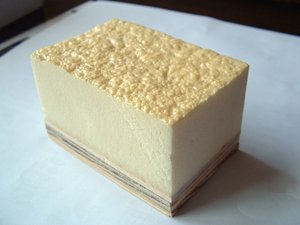

These machines produce foams with high processing pressures and are ideal for producing rigid foams. They use a high-pressure mix head to mix the foam components that might include: isocyanates, water, and blowing agents at a high pressure before injecting it into a mold. High-pressure foaming machines are extensively used in the refrigeration, construction, and automotive industries to make rigid foam products with high insulation properties. The foam produced in this manner has a more uniform cell structure compared to that produced by low-pressure machines. The disadvantage of high-pressure foaming machines is that they have a more complicated operation and require skilled technicians to handle them precisely. Also, their maintenance costs can be higher because of the high-pressure components and systems involved.

Integrated spray systems:

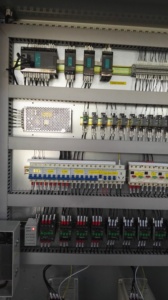

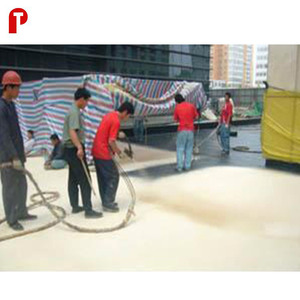

These systems have combustion heating systems inside the foaming machine. It is used to make rigid foam with a high degree of accuracy and precision such as UPVC window filling foam and isocyanate (MDI) wall spray insulation foam. It is ideal for on-site applications where the foam needs to be sprayed to fill cavities or for insulation purposes. The machine will usually feature a digital display that shows the temperature and pressure of the components being mixed and pumped out of the nozzle. An integrated spray system has the advantage of being a versatile tool making it easier to carry out different tasks. Because it can spray foam, blow bubbles, and mix and pump other types of liquids, it reduces time and labor costs by applying only one machine for all these functions.

Some integrated spray systems use an airless spray technique where high-pressure pumps are used to foam the mixture out rather than using the air to spray the foam. An airless spray system reduces overspray and improves the accuracy of the application, especially when using a smaller tip size to spray the foam through a high-pressure pump.

Understanding the performance characteristics of the PU foam injection machine helps manufacturers know how best to use it and take care of it. Some essential specifications include the flow rate, mixing ratio, as well as pressure and temperature settings.

Regular maintenance helps keep the foaming machine running well and prevents problems that could break down important production parts. Here are some essential maintenance tips to ensure long-lasting performance, safety, and efficiency.

The main purpose of the foaming machine is to create and spray polyurethane foam, a material that is widely used for insulation, cushioning, packaging, and sealing. This foam is not only used for thermal insulation and energy efficiency but also for fireproofing, soundproofing, waterproofing, sealing, pest control, and protective coating. Its versatile nature means it can be used in both construction and manufacturing industries.

In the construction industry, the foaming machine has a number of important applications. One of the most common uses is for wall panels and the insulation of roofs, windows, doors, pipes, and other elements. Apart from this, the foam batching machine is also used to manufacture substrates and panels for flooring. This includes creating a seamless and well-insulated floor area.

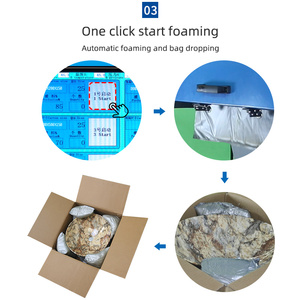

In the furniture and packaging realm, the foaming machine does wonders by cushioning products, especially fragile or delicate items. It serves to minimize impact and provide protection to both the item and the end user. Another famous application of the foaming machine is for mold-making and casting. The machine is used to create molds for complex shapes that require light-weighting, which is done by the automotive and aerospace industries. Here, the foam is typically combined with epoxy or fiberglass to produce a lightweight composite.

In addition to this, the foaming machine also helps in creating decorative items such as faux wood, stone, or other organic patterns. These are predominantly used in the theater and movie industries or even in tradeshow booths and exhibits. Besides, polyurethane foam is also used to fill voids and spaces in irregular areas and gaps such as between pipes, electrical conduits, and holes in walls.

Lastly, the foaming machine serves many other purposes as well. This includes being used to create thermal mass storage systems, as a base for refrigerated display cases, and in the automotive and aerospace industries for sound damping and vibration control.

Production demand analysis:

Determine the production quantity and frequency required for purchasing machines based on business needs. This helps set the foaming capacity and frequency of use for the selected machine.

Equipment compatibility:

Check if the foam machine for polyurethane is compatible with existing production lines and equipment. Ensure it can seamlessly integrate into the current production system while avoiding additional costs for transformation and adaptation.

Easy operation:

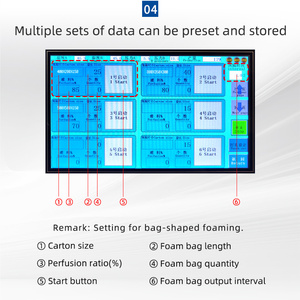

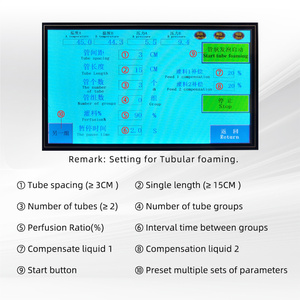

Choose machines with user-friendly control interfaces and operation systems. It's important to consider the training time and cost for employees and opt for equipment that makes operation and adjustment simpler and faster.

Foam quality:

Choose machines that can provide a stable supply of raw materials and maintain uniform quality. Ensure the selected machine meets the commercial standards required for the product to maintain competitiveness in the market.

Maintenance services:

Consider the supplier's maintenance service and technical support. Choose suppliers who offer prompt maintenance, repair services, and technical support to ensure the long-term, stable operation of the machine.

Cost considerations:

Balance the initial investment, operating costs, and maintenance costs of the machine. Consider the overall cost of the life cycle and return on investment to make a more economical and reasonable choice.

Q1: Can a Polyurethane Foam Foaming Machine make flexible foams?

A1: Yes. Flexible foam products include furniture cushions, car seats, mattresses, and many other applications.

Q2: Can a Polyurethane Foam Foaming Machine make rigid foams?

A2: Yes. Rigid foam products include insulation panels, structural components, and various building materials.

Q3: What are the storage requirements for polyurethane foam machine ingredients?

A3: Polyurethane components should be stored in a cool, dry place, away from direct sunlight or heat. It's important to keep them tightly sealed to prevent contamination or moisture absorption.

Q4: What are some common troubleshooting tips for polyurethane foam machines?

A4: Check for clogs or blockages in spray guns or mixing heads. Ensure adequate material supply and pressure levels. Inspect the electrical components and connections for any issues. Clean and maintain the equipment regularly to prevent problems.