(13748 products available)

Machines that apply polyurethane foam are known as spray machines.

Manual Spray Machines:

Users operate manual machines. Operators mix the components of the foam on their own and then manually trigger the spraying by hand levers or buttons. Smaller jobs where foam application is not complicated or where foam coverage isn't critical are best suited for these machines. As a rule, they cost less than other types of spray equipment.

Air-Driven Spray Machines:

Machines that use compressed air to drive the foam mixing and spraying process are called air-driven. Air motors within the machines perform mixing, proportioning, and/or pumping operations. Some air-driven machines have auxiliary air systems for atomization during spraying. These can be used for both rigid and semi-rigid foam formulations. They're widely used in the machinery industry for diverse applications, especially insulating and sealing applications.

Greenguard Certified Machines:

GreenGuard machines have specific environmental features. They emit fewer pollutants into the atmosphere. This is important for businesses that want to reduce their impact on the environment and better meet government regulations.

Electric Pump Spray Machines:

The driving force behind the spraying of foam is an electric motor in electric pump machines. Electric motors provide the pressure needed to transport the foam materials, which are then mixed and sprayed. The option of proportioning pumps for precise formulation handling is available with these machines. Versatile applications and varying foam types can be tackled with electric pump spray machines.

Platinum-Catalyzed Spray Machines:

Platinum spray machines have specific catalytic systems for foam formation. They ensure precise control over the foam's properties, which is essential in some applications requiring customization. For instance, within the machinery industry, these may be employed to insulate cryogenic pipelines. For such cases, operators need to have an accurate control of the foam characteristics. The machines also help achieve a low-temperature porosity.

Hydraulic Spray Machines:

The driving force for the spraying action in hydraulic machines is oil-based systems. This gives a certain degree of power and flexibility, making them suitable for big jobs needing foam to be applied in large quantities. Also, some of the hydraulic-driven machines are proportioning pumps. That is, they precisely measure and deliver foam components. They are commonly used for insulation, sealing, and structural applications.

Built-in Generators:

Some spray machines have built-in generators to supply the power needed for foam formulation and application. This makes the job more convenient, especially if there is no power source available in the work area. The generator also helps unify the equipment needed for the spraying operation.

Contractor vs. Industrial Models:

Generally, polyurethane spray machines are designed for contractors or industrial use. Contractor models are portable, easy to use, and designed for the needs of contractors. They can handle various jobs, from insulation to sealing and are designed for smaller-scale, daily-use applications. Industrial-grade machines are larger, more durable, and able to do more tough jobs fast. They deal with high volumes of foam production and spraying. Applications in complex industries where strength and precision are important require industrial spray machines.

Packaging Industry:

In the packaging business, the polyurethane spray machine makes containers and protective packaging. It sprays foam that hardens into lightweight boxes. These boxes shield products during shipping, preventing damage. The foam also offers insulation for temperature-sensitive items.

Automotive Sector:

For cars and vehicles, the machine applies insulation in interiors like doors, roofs, and the cabin. It sprays a liquid that turns into a solid, providing heat and sound control. This improves comfort by keeping temperatures steady and minimizing noise within the vehicle.

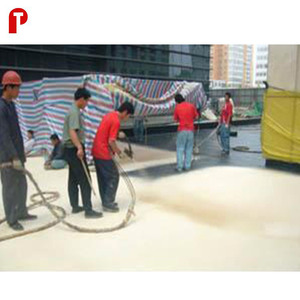

Construction:

In construction, the spray machine applies insulation to buildings. It sprays foam on walls, roofs, and attics. The foam expands and hardens, creating a seal that cuts heat loss. Better insulation leads to lower energy bills by reducing heating needs.

Furniture Making:

When manufacturing furniture, the machine adds cushioning to seats and sofas. It sprays a mixture that forms soft foam, providing padding for chairs, benches, and couches. This foam gives ergonomic support and comfort for users when sitting or resting.

General Industry:

In various other industries, the spray machine coats items with a polyurethane layer for protection. It covers things such as tools, machinery parts, and equipment. The polyurethane layer defends against wear, improving lifespan and durability. It resists abrasion, helping protect against damage from frequent use or contact.

Work requirements analysis:

Before purchasing, buyers should first consider their own work needs. Buyers should figure out the types of materials they need to spray, the surfaces they need to spray, and the amount of work they need to do. This will help buyers choose a spray machine that is suitable for their needs.

Device type selection:

There are several different types of spray machines. Buyers should choose the right machine based on their needs and working environment. For example, if a buyer needs to work in a large space, they may want to consider an airless spray machine because it does not require an air compressor. If the buyer needs to handle more detailed work, they might consider a fine-finish spray machine.

Equipment performance comparison:

Buyers should compare the performances of different spray machines, such as spraying power, spray width and adjustability, etc. Buyers should choose a spray machine with suitable performance based on their own needs.

Brand and model selection:

There are many well-known brands of spray machine generators, each offering different models. Buyers can choose a spray machine from a well-known brand, which usually has a better guarantee of quality and after-sales service.

Ease of use and portability:

Many spray machines offer features such as easy operation and portability. For example, a spray machine with an automatic lubrication system reduces the need for manual lubrication. In addition, options such as lightweight design and roller wheels make it easier to move. These features improve the efficiency of use.

Safety features:

Some safety elements, such as low-pressure safety and emergency stop switches, are helpful in preventing accidents. Choosing a spray machine that has these features will ensure the user's safety.

Parts and accessories:

Some spray machines provide extra parts and accessories, like nozzles and filters. These parts can meet different needs and improve versatility.

Q1: How does a spray foam machine work?

A1: The foam spraying device first heats the isocyanate and polyol blend components before pressurizing them. Then, the heated and pressurized components are mixed in the spray gun chamber, where they react and foam. Lastly, the mixture is sprayed onto a surface.

Q2: What are the types of foam spray machines?

A2: There are two main types of foam spray machines: air-assisted and air-less spraying machines. In air-assisted machines, air compression forces the material out of the nozzle. Alternatively, air-less spray devices use high-pressure pumps to push material through the tip.

Q3: What is the spray foam machine made of?

A3: A polyurethane foam spray machine consists of five main parts: the heated hoses, the spray gun, the mix chamber, the pump, and the pressure regulator. Some machines may also have digital monitors and barrels for storing foam components.

Q4: Can a foam spray machine be used indoors?

A4: Users should not use foam spray machines indoors because they require spraying isocyanate and polyol components that emit toxic fumes. If necessary, users should ensure adequate ventilation, wear proper safety equipment, and take necessary precautions.