Types of Polyurea Foaming Spray Machines

A polyurea foaming spray machine is an equipment used to apply spray polyurethane (or polyurea) elastomer, which is a special chemical compound used for coating surfaces or creating foam. The spray works by combining two liquid components that expand when they are sprayed (or mixed) together. These machines come in different types, but all can be powered by air, electric, or hydraulic means.

- Air- driven Spray Machines: This type of machine uses compressed air to move the liquid components from the supply buckets through heated hoses and into the spray gun. It's really common for the machines to spray (up to) 15 gallons per minute. Air-driven machines work really well for smaller projects or when the coatings are put on softer stuff. But, you know, they might not spray as smoothly for really thick liquids or huge jobs. Sometimes, the air compressors they use can be noisy, too.

- Electric Spray Machines: Electric machines use electricity to power pumps that push the liquid materials out. They are usually smaller and lighter than air-driven machines. So, this makes it easier to move them around when working. The good thing is that electric machines have fewer noisy parts than air-driven ones. This means they aren't that much noise pollution or bother to people living nearby. Also, it might be very possible for anyone to use them indoors than air-driven ones. However, if the job is big, electric machines might not be strong enough to spray long-lasting foams or coatings. It could take a bit longer to finish.

- Hydraulic Spray Machines: These hydraulic machines use the power of liquid pressure (hydraulic pressure) to push out the foam or coating. They're made real tough so they can spray a lot of stuff quickly and continuously for a long time. People mostly use them for big jobs where there's a really big need to spray a whole lot of liquid all at once that's like super strong and heavy duty. Big, powerful hydraulic pumps are where all this strong liquid pressure comes from.

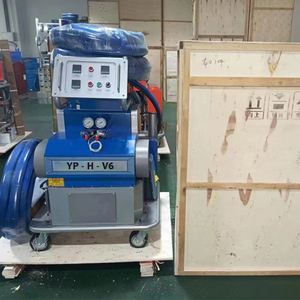

Specifications and Maintenance of Polyurea Foaming Spray Machines

Specifications

-

Heater power:

The heater power of a polyurea spray machine is the power of the heating element used to heat the polyurea material before spraying. Common heater powers are usually between 15 and 30 kilowatts. Higher heater power can heat materials faster and maintain a more stable temperature, which is suitable for spraying in a polyurea mobile van.

-

Working pressure:

The working pressure of the machine is to spray two-component polyurea materials, such as the high-pressure delivery of raw materials. The working pressure is usually between 15 and 30 MPa.

-

Airflow:

The airflow of the polyurea foaming spray machine is the amount of compressed air flowing through the machine in the spraying process. The airflow is usually between 3 and 12 cubic meters per hour. The airflow can provide sufficient air power for the spray nozzle, ensuring the spray quality and efficiency.

-

Volume:

Both the northwest and our polyurea spray machines are packed in strong packing boxes. The dimension for D50 polyurea spray machine is 50cm*60cm*105cm, and the weight is 66kg. For D65 polyurea spray machine, the dimension is 43cm*62cm*103cm, and the weight is 78kg.

-

Mixing speed:

The mixing speed during spraying of the polyurea foaming spray machine is usually between 1000 and 3000 revolutions per minute. Higher mixing speeds can make the mixing more uniform and better spray out the material.

Maintenance

- Clean: Regular cleaning is one of the important maintenance methods. After use, clean the residue from the nozzle, mixing head, etc., using cleaning agents and special tools. Meanwhile, clean the surface of the machine and the dust and dirt around it to keep it clean.

- Lubrication: Apply lubricating oil to moving parts, such as guide rails, sliding blocks, etc. Periodically add lubricating oil to the pump and spray gun to ensure smooth operation and reduce wear.

- Wear parts inspection and replacement: Inspect the polyurea spray machine's wear parts, like nozzles, filters, and mixing heads, regularly. Clean or replace them to ensure the stable operation and spray effect of the machine.

- Electrical system maintenance: Pay attention to keeping the electrical parts dry. Check the fastening and insulation of the electric wires and connectors. Clean and remove the dirt from the electric switch and socket.

- Hydraulic system maintenance: Inspect the hoses, joints, and cylinders of the hydraulic system for leaks or wear. Check the hydraulic oil level and quality and replace or add it as required.

- Prevent dust and moisture: Cover or put away the equipment when not in use so that it is prevented from dust and moisture. Ensure good ventilation and air conditioning at the storage place.

- Regularly inspect and maintain the spraying machines for good mechanical performance, electrical, and hydraulic functions. Check the fastening and electrical connections of the whole equipment, hoses, etc., to ensure the machine can work smoothly and reliably.

Application scenarios of polyurea foaming spray machines

-

Construction industry:

In the construction industry, a polyurea spray machine can be used to spray polyurea waterproofing on roofs, underground garages, swimming pools, tunnels, and other facilities. The machine applies an elastic waterproof coating that can effectively meet the waterproofing requirements of buildings in various places.

-

Insulation industry:

There are many uses of the polyurea spray gun in the insulation industry. For instance, the machine can be used to apply insulation materials on refrigeration equipment, pipelines, cold storage, frozen molds, oil tanks, and chemical storage vessels, which improves the energy-saving effect. Moreover, the spray machine can be employed to apply insulation coatings for electrical equipment, such as transformers, switchgear, and motor electrical insulation varnish.

-

Car modification industry:

In the car refitting industry, using a polyurea waterproofing spray machine to modify vehicle underbody anti-collision coatings can help protect the vehicle from gravel impact and corrosion, reducing the risk of damage to the underbody. Additionally, these machines are often used to spray polyurea truck bed liners to protect the truck bed from scratches, dents, and stains. Polyurea is a durable and strong material that bonds tightly to the surface of the truck bed, providing long-lasting protection.

-

Packaging industry:

In the packaging industry, polyurea spray machines can spray foam packaging for the transportation of fragile products. This provides cushioning and protection during transit.

-

Industrial maintenance:

In industrial maintenance, a polyurea spray machine can apply protective coatings to equipment and facilities, such as storage tanks, pipelines, pumps, valves, and other mechanical components. These coatings can prevent corrosion, abrasion, and chemical damage, extending the service life of the equipment and facilities.

-

Flooring industry:

In the flooring industry, polyurea spray machines can be used to construct protective floors in various places, such as workshops, warehouses, laboratories, electrostatic fields, and chemical manufacturing plants. The flexible and durable floors can improve the rather harsh environmental workplace.

How to Choose Polyurea Foaming Spray Machines

When purchasing a polyurea foaming spray machine, buyers need to consider several factors to ensure they get equipment that meets their specific needs.

- Material Compatibility: The item to be sprayed will determine the material compatibility of the machine. Some machines are designed to work with specific polyurea formulations, so it's essential to ensure that the selected foaming spray machine will work with the polyurea material that will be used for the project.

- Machine Capacity: This represents the volume or amount of foam that the machine can produce. It is typically measured in liters or gallons per minute. Consider the size of the projects to be undertaken. For smaller projects, a machine with lower output may be sufficient. However, larger projects will require a machine with a higher output to save time and ensure efficient completion.

- Mixing Requirement: Products have different mixing requirements, which are determined by the chemical makeup of the polyurea. Some machines offer precise mixing ratios and control, which is crucial for the success of the application. Buyers should look for machines that provide accurate mixing to ensure optimal foam performance and avoid issues related to inconsistent mixing.

- Heat Control: Polyurea materials are sensitive to temperature, and proper heat control during spraying is essential for achieving the desired foam properties. When buying a polyurea foaming spray machine, buyers should prioritize models with effective heat control systems that maintain consistent temperature throughout the spraying process.

- Machine Weight and Size: The weight and size of a polyurea foam spray machine can significantly impact its maneuverability and ease of use on the job site. Buyers need to consider the dimensions and weight of the spray foam machine to ensure that it is portable and easy to handle during installation. With this, operators can easily move the machine around and position it comfortably for accurate spraying.

- Power Source: Consider the power source of the machine, as this plays a role in determining the performance, efficiency, and application range of the equipment. Buyers should choose a power source that fits their needs, whether it's electric, gas, or air-driven, to ensure reliable operation and compatibility with their working environment.

- Nozzle Types: Different projects may call for other application methods and patterns, so it's essential to have a machine that accommodates various nozzle types. Nozzles can differ in sizes, shapes, and designs, each engineered to produce a specific foam application. By selecting a spray foam machine with interchangeable nozzle options, users can achieve precise coverage, control, and adaptability to meet their project's requirements.

Polyurea foaming spray machine Q&A

Q1: What is the reason for adding air to the polyurea spray foam machine?

A1: The addition of air helps the material to expand further, allowing it to cover a wider surface area.

Q2: Why do goods get heated before they are placed in the polyurea spray foam machine?

A2: It is essential to heat the components of the spray foam in the machine to raise their temperatures above 120F. This enhances the reactivity of the isocyanate and resin, resulting in better foam generation.

Q3: What safety precautions should be taken when using a polyurea spray foam machine?

A3: It's crucial to wear personal protective equipment, including goggles and respirators, and to ensure proper ventilation at the spraying location. Additionally, handling chemicals with the appropriate safety data is essential.

Q4: Can consumers buy used polyurea spray foam machines?

A4: Yes, some people consider acquiring a second-hand machine to save money. It is essential to inspect the machine closely and ensure that it is still functioning properly and compare the performance with new ones to be sure that it will meet the needs.