(840 products available)

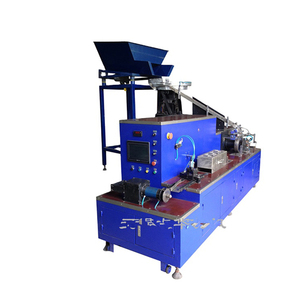

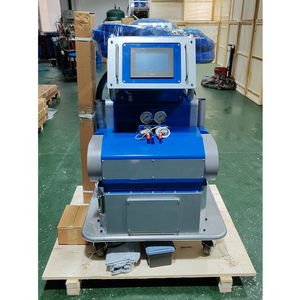

Poly foam injecting machines come in various types, each designed to meet specific manufacturing needs. The table below summarizes some of the most common types of poly foam injecting machines:

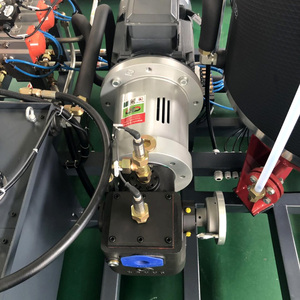

Proper maintenance of the polyfoam injection machine ensures consistent operation and optimal foam quality. Regular inspections should be done to identify any signs of wear, damage, or leaks. All tank and pump components should be checked for leakages, while the drive system should be inspected for any loose or worn-out belts and cables.

The foam injecting machine must be cleaned regularly to avoid material buildup and clogs that can impair its operation. This may involve flushing out unused chemicals and foaming agents from the machine and cleaning any removable components with suitable cleaning agents. Maintenance of the machine may also involve lubricating moving parts and cleaning filters. Machine calibration should also be frequent to ensure accurate foam mixing ratios and injecting volumes.

Routine checks should be done on the electrical and hydraulic systems to ensure secure and tight connections. This helps to avoid issues such as electrical failures or pressure losses that may negatively affect the quality of the foam output. The work environment should also be inspected to ensure it's free of contaminating elements, including dust and moisture, which can interfere with the operation of the foam injection machine.

The application scope of poly inject foaming machines is very wide. They can just be used for the manufacturing of polyurethane foams, including any more specialized or non-traditional use of such devices.

Here are some common application areas for which these machines would usually be used:

Packaging materials:

As mentioned before, the primary use of a poly foam injecting machine is to produce packaging foam. Such packaging foams would be used to protect fragile or valuable goods during transit.

Upholstery:

Electronics manufacturers also use these devices to make cushion seats and other upholstery items. However, they are not usually considered "Uph-stuffing

Home and automotive applications often use soft foam fitted materials to make things like office chairs, car seats, ergonomic computer peripherals, etc. These items are usually soft and comfortable to touch. Phones are usually soft and comfortable to touch.

People sometimes would not think that a device that adsorbs sound, like soundproofing foam, could be part of an electronic device. However, that's exactly the case.

Fitted materials are an application of foam that many electronics manufacturers use. However, the end-users (buyers), which in this case could be the parents, would not even know that a foam stuffing device made up of was made up of a foam stuffing device.

Besides, there could also be other entries, such as "upstairs" or "downstairs," where things like kids' toys, pet accessories, and human input/output electronics devices are included.

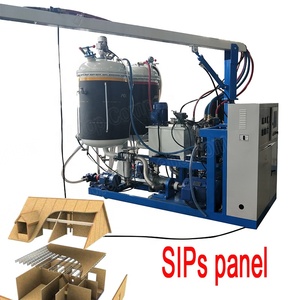

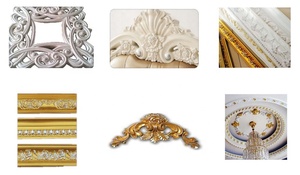

Construction industry:

In the construction industry, these machines are frequently used to manufacture insulation panels. Such panels are then used to provide thermal insulation for buildings. Other uses of foam in the construction industry include filling materials for cracks, cavities, and gaps, soundproofing materials, cushioning for structural elements, and protective coatings.

Automotive and aerospace industries:

In automotive and aerospace engineering, foam injecting devices are used to create insulation materials. These materials provide thermal insulation for vehicles and aircraft, sound insulation foams, and cushioning materials for seats, dashboards, and other interior elements.

Medical and healthcare industry:

In the healthcare industry, medical-grade foams are produced using foam-injection devices. These foams are typically used for making cushions, mattresses, and seating systems for individuals with disabilities or the elderly. They can also be used as soft padding and cushioning for medical equipment.

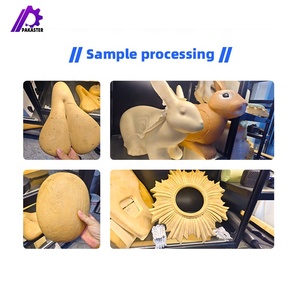

Creative and artistic applications:

Some artists and creative professionals use foam-injection devices to create unique sculptures, art installations, or props for theater and film productions. This is usually done so that the requirements for weight reduction and design flexibility are met.

When purchasing a poly foam injection machine for business use, several important factors must be considered to ensure it fulfills production needs and offers good value for money.

Production Capacity:

Determine the machine's foaming output per unit time. This is usually specified in liters or cubic meters per hour. Select a model that matches business requirements to meet demand efficiently without creating production bottlenecks.

Material Compatibility:

Ensure the machine can process the types of foam raw materials the business intends to use. Check compatibility in terms of polymers, isocyanates, surfactants, and other specific constituents.

Automation and Controls:

Decide the desired level of automation. Options range from fully automated machines with computer controls and programmable foaming parameters to manual models requiring more operator input. Choose an appropriate balance between convenience, efficiency, and operating complexity.

Machine Size and Weight:

The overall dimensions and weight need to be suitable for the intended production line setup. Ensure the dimensions allow for smooth integration into the workspace, while lifting and transportation are feasible.

Energy Consumption:

Consider the energy utilized during operation, like electricity, compressed air, or gas. Look for efficient models that minimize energy usage to reduce operating costs over the long term.

Maintenance and Servicing:

Evaluate how easy it is to maintain the machine and provide necessary servicing. Check factors like component accessibility, required maintenance schedules, and the availability of replacement parts.

Supplier Reputation:

Choose a dependable manufacturer after examining commercial concerns like warranty length, customer support services, and the guidance provided during installation and training. Go for a recognized global brand or a local supplier with a proven track record.

Q1: Where does the foam injected by a Polyurethane Foam Injection Machine go during the manufacturing process?

A1: This area is called the fill area and is usually located in the mold's interior cavity where the desired object shape is.

Q2: What is the role of the mixing chamber in a Polyurethane Injection Molding Machine?

A2: The mixing chamber is where the two components of polyurethane are mixed simultaneously before entering the injection nozzle.

Q3: What Type of Foam Does a Polyurethane Foam Injection Machine Create?

A3: It creates rigid foam, which provides structural support and insulation.

Q4: How does the speed of the injecting machine affect production?

A4: Faster speeds may lead to the breaking of molds, while slower speeds could affect the quality of the foam and production efficiency.