(413 products available)

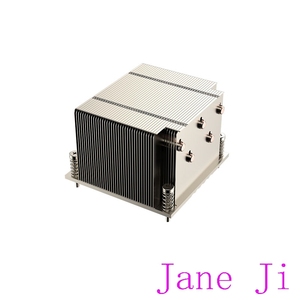

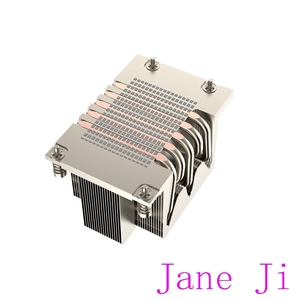

A passive heat exchanger is a device that transfers heat between two or more fluids without using external power. The passive heat exchanger is the core component of the passive heat exchanger. There are various types of passive heat exchangers, each suitable for a specific application. They include:

As businesses in various industries continue to adopt passive heat exchangers, it is essential to understand their specifications and maintenance requirements to ensure optimal performance.

Heat transfer capacity: This is the total amount of heat that the passive heat exchanger can transfer over a given period. It is a critical specification for users who need to know the maximum capacity the exchanger can handle to avoid overloading.

Material and compatibility: Passive heat exchangers can be manufactured from different materials, each designed to transfer heat from various sources. Users need to choose a material that is compatible with the heat source to ensure efficient heat transfer and optimal performance.

Heat transfer coefficient: This is the measure of how well the exchanger can transfer heat. It is the value that shows how effective the exchanger is at moving heat from one place to another. Users are interested in this value, as it determines the efficiency of the exchanger.

Flow rate: This is the rate at which liquids or gases move through the exchanger. It is a crucial specification for users who need to know how quickly the gas or liquid will move through the exchanger and how it will affect the heat transfer process.

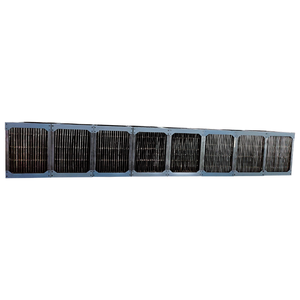

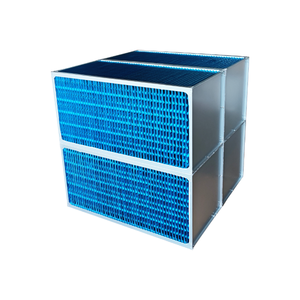

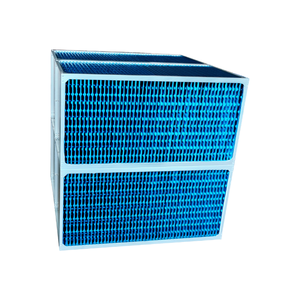

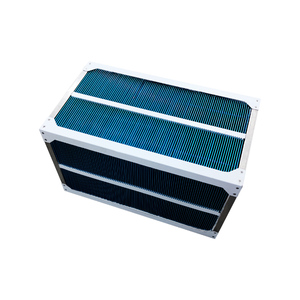

Size and form factor: This includes the length, width, and height of the exchanger. It also includes the shape and the surface area of the exchanger. Users are interested in this specification, as it determines the exchanger's suitability for installation.

Regular inspection: Users should inspect the exchanger for signs of wear or damage to the tubing and fins. If there are any signs of damage, it should be checked and repaired promptly.

Cleaning: The exchanger should be cleaned at least twice a year using a non-corrosive cleaning solution. This is to remove any dirt, debris, or scale build-up that could reduce its efficiency.

Corrosion protection: In areas with high humidity or corrosive environments, users should apply a corrosion-resistant coating to the exchanger. This helps to protect the exchanger's surface from corrosion and extend its lifespan.

Fin straightening: The exchanger's fins should be straightened regularly to maintain the optimal heat transfer surface area. This helps to promote efficient heat transfer.

Fluid quality: Users should monitor the quality of fluid flowing through the exchanger to prevent scale build-up, corrosion, and biological growth. If any contaminants are found, they should be treated promptly to avoid damaging the exchanger.

A passive heat exchanger is essential in various industries and applications that require the transfer of heat from one medium to another. Here are some usage scenarios for passive heat exchangers in different industries.

In the energy industry, passive heat exchangers are used in power plants to recover and transfer heat. They are used in steam generators, condensers, and boilers to cool down high-temperature fluids and to increase the efficiency of power generation. Passive heat exchangers are also used in solar panels to transfer heat from solar collectors to heat storage tanks or to the atmosphere to increase the efficiency and lifespan of the solar panels.

In the chemical industry, passive heat exchangers are used to cool down high-temperature chemical reactions. They are used in distillation columns, reactors, and fractional towers to transfer heat and maintain the desired temperature. Passive heat exchangers are also used in chemical plants to recover waste heat and increase energy efficiency.

In the food industry, passive heat exchangers are used to cool down and preserve food products. They are used in pasteurization, sterilization, and aseptic processing to transfer heat and kill bacteria. Passive heat exchangers are also used in refrigeration and freezing systems to maintain the quality and safety of food products.

In the automotive industry, passive heat exchangers are used to cool down the engine and transmission. They are used in radiators, intercoolers, and oil coolers to transfer heat and maintain the desired temperature in the engine and transmission. Passive heat exchangers are also used in air conditioning systems to cool down the passenger compartment and increase comfort.

In the medical industry, passive heat exchangers are used in medical devices and equipment. They are used in MRI machines, CT scanners, and X-ray machines to transfer heat and cool down the components. Passive heat exchangers are also used in laser systems and surgical instruments to maintain the desired temperature and increase the safety of the patients.

When choosing a passive heat exchanger, it is important to consider several key factors to ensure the selection meets the needs of the application.

Q1: What is the difference between a passive heat exchanger and an active one?

A1: As their names suggest, passive heat exchangers do not rely on any mechanical devices, such as fans or pumps, to transfer heat, while active heat exchangers do. This makes passive heat exchangers less energy-intensive and more suitable for use in explosive environments.

Q2: What are the types of passive heat exchangers?

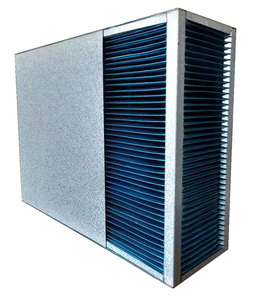

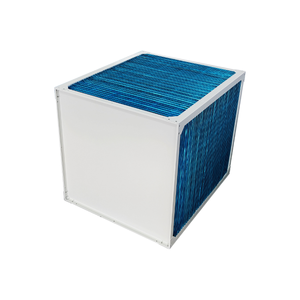

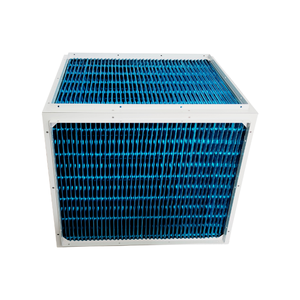

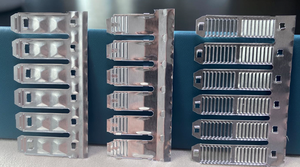

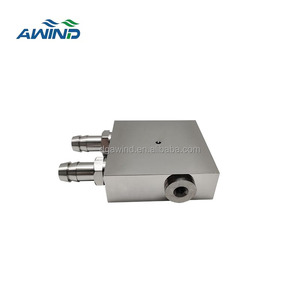

A2: Two common types of passive heat exchangers are the plate exchanger and the shell and tube exchanger. The plate exchanger commonly consists of multiple thin plates arranged in a way that allows for heat transfer. This can be used in a variety of industries, including gas and oil. The shell and tube exchanger is a more traditional design that consists of a series of tubes inside a cylindrical shell. This design has a large surface area that can be used to transfer heat efficiently.

Q3: What are the benefits of passive heat exchangers?

A3: Passive heat exchangers are much more energy-efficient than their active counterparts, which means that they have lower operating costs. They also produce less noise than active heat exchangers, which can be beneficial in some applications. Finally, they are less likely to experience mechanical failure.