(1032 products available)

Open top chillers are manufactured in various types. Each type has different chilling systems and applications. Thus, this section will explore the diverse types of open-top chilled.

Most open-top chilled, use the traditional refrigeration system. They circulate a refrigerant through evaporator coils positioned in the pool of chilled liquid. The refrigerant absorbs heat from the liquid, cooling it down.

The cooled liquid is then recirculated to maintain the desired temperature. This method is effective for ensuring the consistency of temperature control. For most foods and beverages, temperature control is vital to ensure food safety and freshness.

An open-top recirculating chiller is similar to an aquarium chiller. It maintains a constant temperature in a large, open, refrigerated space. It uses pumps to circulate the chilled liquid throughout the unit.

The circulation helps evenly distribute the low temperature. This type is commonly used in large-scale commercial applications. These applications may include restaurants and supermarkets.

A high-efficiency open-top chiller features advanced insulation and heat exchange technologies. These enhance its energy efficiency compared to conventional models. This model is designed specifically for businesses with high refrigeration needs.

An example is a food processing plant. In such areas, high energy costs can significantly impact profitability. They optimize cooling performance while minimizing energy consumption.

Open-top, chilled, can be classified as air-cooled or water-cooled. An air-cooled model uses ambient air to dissipate heat. It is then cooled to maintain the temperature of the chilled liquid.

Conversely, a water-cooled chiller uses a cooling tower or water source. It is then cooled to remove heat. Air-cooled open-top chillers are easier to install.

The chillers do not require a water supply. On the other hand, water-cooled models are more efficient in large-scale operations. They provide better temperature control.

Open top chillers are favored in various commercial and industrial applications due to their robust design and efficient cooling capabilities.

The food and beverage industry relies heavily on open-top chillers. It is because they store large quantities of perishable items. The chillers maintain low temperatures to ensure the freshness of food products.

They also enable quick access to items like meats, dairy, fruits, and vegetables in a retail setting. Supermarkets usually install these chillers.

For food processing facilities, the chillers help manage the temperature during manufacturing processes. These include mixing, blending, and marinating.

In addition, the open design makes it easier for users to see and retrieve products. Thus, it ensures optimal inventory management.

In the pharmaceutical industry, precise temperature control of open-top chillers is essential. It is because the industry stores temperature-sensitive medications, vaccines, and biological samples.

One of the greatest benefits of these chillers is that they maintain the integrity of these products. They do so by preventing spoilage or loss of efficacy. Besides storage, the chillers are employed in laboratories.

In labs, the chillers provide temperature-controlled environments for experiments that require specific low temperatures.

In data centers, temperature control is crucial to prevent server overheating. Open-top chillers manage this cooling requirement. They help dissipate heat from server racks and other critical equipment.

This ensures that systems operate smoothly. In addition, these chillers can be used in manufacturing facilities for electronic components.

Here, they cool down production processes. These include soldering or component assembly, which can generate significant heat. Overall, the open chiller provides a reliable method of heat management.

Open chiller tops have distinct features that enable them to meet diverse client needs. Here are the key features of the chillers:

Good thermal insulation is one of the most important features of an open, top chiller. Proper insulation is necessary for its cooling efficiency to be effective. Common insulation materials are polyurethane foam or polystyrene.

They help minimize heat gain from the environment. Thus, reducing energy consumption. This is critical for businesses that require round-the-clock refrigeration. Good insulation also helps maintain consistent low temperatures in the chiller.

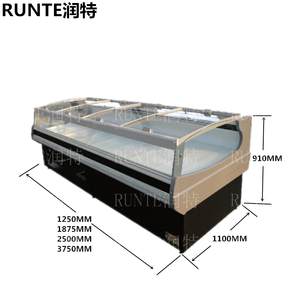

These chillers are designed to store large volumes of chilled liquids. The liquids include water, solutions, or other fluids. It ensures that large quantities of products users must refrigerate are always available.

This is critical for high-demand environments like supermarkets, restaurants, and food processing plants. The chilling systems can handle large product loads without compromising temperature.

Most open-top chillers have a large, open-top space. It allows users to easily see and retrieve products. This simplifies inventory management and product accessibility in large commercial settings.

Thus, reducing the need for complex storage procedures. Also, most chillers have removable lids or covers. These allow for easy cleaning and maintenance.

Most open-top chillers are constructed using stainless steel. Sometimes heavy-duty plastics make them suitable for harsh industrial environments.

They can endure frequent use, exposure to moisture, and potential chemical damage. These materials also resist corrosion to prolong the chiller’s lifespan.

These factors include the water-cooled chiller and the ambient air. They help users remove heat and, therefore, reduce operating costs on the chillers. This makes them an affordable option for large-scale refrigeration needs.

Choosing the right one for clients requires asking the right questions. This is because the right factors to consider when selecting an open, top chiller depend on a client’s unique needs. The following are factors to consider when choosing the chillers.

Cooling capacity refers to the unit’s ability to maintain a desired low temperature. This is critical for clients with a large inventory of perishable items. Going for a chiller with large cooling capacity is essential for them.

However, clients with small spaces or retail operations do not require a unit with a large capacity. They will find a unit with a small capacity sufficient for their needs. Note that an oversized chiller is a large one.

It can lead to energy wastage and many short cycles. In turn, these short cycles can negatively impact food safety. On the other hand, undersized units cannot handle the load resulting in increased temperatures.

Energy-efficient models have advanced features. Some of the features include high-efficiency compressors and better insulation. These features help reduce energy consumption.

These features reduce operational costs. They are especially critical in environments with continuous refrigeration needs. Moreover, energy-efficient open-top chillers qualify for environmental rebates.

This is because different types of open, top chillers have unique benefits when compared to each other. For example, air-cooled chillers are more versatile. This makes them suitable for locations with limited water access.

On the other hand, water-cooled chillers are more efficient for large operations. It si because they offer superior temperature control. Therefore, it is vital to consider what the client’s accessibility to water is like.

Open top chillers have a low-maintenance system. This is because they have several easily cleanable components. The components include removable lids and simple coolant circulation systems.

Clients who prioritize low-maintenance equipment will benefit from these models. Also, some models come with self-cleaning features. They reduce the need of manually cleaning the units frequently.

An open chiller ensures optimal refrigeration storage for low-temperature products. They are commonly used in the food and beverage industry to store perishables. They also store other temperature-sensitive products like medication and biological samples.

Most open top chillers use R134A refrigerant. This is mainly because the refrigerant has ideal thermodynamic properties for a wide temperature range. The refrigerant is also environmentally friendly.

It is because it does not deplete the ozone layer. In addition, R134A is non-toxic and non-flammable. It ensures a sufficiently safe working environment for users.

These chillers use both factors to help reduce users’ operational costs.

First, water-cooled models use a cost-effective cooling method. It costs less than electricity usage. In addition, many models are energy-efficient. They minimize energy consumption, reducing electricity bills.

The former is a refrigerated unit designed to store perishable items in large quantities. The latter provides a controlled low-temperature environment to store products.

In addition, the chillers are more accessible for inventory management than a refrigerated room. They are also easier to use and are space efficient.

Yes, it is possible to install an open, top chiller outdoors. Several models are designed specifically for outdoor use. They will offer climate-resistant features. However, the manufacturer must ensure the user does not expose the chiller to extreme weather conditions.

Installing sensors to monitor temperature and inventory levels will improve the system’s efficiency. The sensors will provide real-time data that the users can analyze. Also, regular maintenance will ensure that the system operates at peak efficiency.