(365 products available)

There are several types of N eupex couplings, each designed to accommodate different operational requirements. These types include:

Standard N eupex Couplings

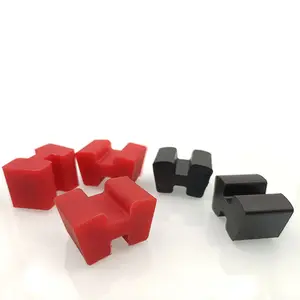

Normally, the standard N eupex coupling is the most popular type used in industries. It's primarily used to transmit torque between two shafts while allowing for some misalignment. Usually, they are made from high-quality plastic and rubber materials, providing flexibility and dampening vibrations.

Heavy-Duty N eupex Couplings

Heavy-duty N eupex couplings are designed for high-load and high-torque applications. Normally, these couplings provide exceptional durability and are commonly used in heavy industries such as mining, construction, and marine.

Corrosion-Resistant N eupex Couplings

These couplings are made from materials that are not affected by aggressive chemicals. Therefore, they are frequently used in the chemical and petrochemical industries, where exposure to corrosive substances is inevitable. They offer longevity and reliability in hostile environments.

High-Temperature N eupex Couplings

High-temperature N eupex couplings are designed to be used in applications that have extremely high temperatures. Normally, they retain their mechanical properties even when exposed to heat. Therefore, they are used in the foundry, glass, and furnace industries.

Custom N eupex Couplings

Custom N eupex couplings are manufactured to customers according to their particular needs. This is based on factors like size, material, and specific operational parameters. Normally, they give the best performance in particular niche applications.

N eupex couplings feature several aspects that make them suitable for many industrial applications. Some of the key features include:

Elasticity

N eupex couplings are primarily made from elastic materials that can flex and absorb stress. This normally helps dampen vibrations and reduces shock loading on connected equipment. Therefore, it improves the overall system reliability and performance.

Anti-Corrosion Properties

N eupex couplings are mostly constructed from materials that are not affected by corrosion. This includes high-quality plastics and rubbers. Therefore, this property ensures longevity even in chemically aggressive environments. That is to say, the Couplings maintain their integrity and performance for a longer period.

Flexibility and Misalignment Tolerance

To put it another way, N eupex couplings are designed to accommodate slight misalignments between shafts. Therefore, they allow for axial, radial, and angular displacement. This flexibility minimizes wear on equipment and reduces the risk of breakdowns. Commonly, it makes them ideal for use in diverse industries.

Torque Transmission

Usually, N eupex couplings are designed to efficiently transmit torque between rotating shafts. Besides, the elastic elements in the coupling help to smooth the torque transmission. This normally ensures consistent power delivery to machinery without causing excess wear.

Easy Installation

Generally, one of the key advantages of N eupex couplings is their simple installation process. Often, they can be quickly mounted or disassembled without special tools. This saves time during both initial setup and maintenance, making them user-friendly for technicians.

Selecting the right N eupex coupling for a given application requires careful consideration of several factors. Here are the key factors to bear in mind:

Alignment

Ideally, one of the primary purposes of N eupex couplings is to offset any misalignment. Therefore, the type and extent of misalignment in the shafts should be considered when selecting a coupling. In addition, radial, axial, and angular misalignments must be accommodated effectively to reduce wear on the connected equipment.

Torque and Load Capacity

Normally, the coupling should be able to handle the maximum torque and load that the system experiences without failing. Therefore, this ensures that the coupling can operate safely and reliably under the expected loads.

Material Compatibility

The custom N eupex coupling material should be compatible with the working environment. Also, it should be able to resist wear, corrosion, and chemical exposure as they are meant to endure. Ideally, N eupex couplings are made from high-quality plastics and rubber. They offer flexibility and durable corrosion resistance.

Operating Speed

Selecting a coupling with the material that can accommodate the required operating speed is important. Normally, high-speed applications may require couplings with superior flexibility and strength. This is to avoid material fatigue and possible breakage.

Maintenance Requirements

Custom N eupex couplings are mostly selected due to their easy installation and low maintenance requirement. Also, they need less frequent inspection and lubrication compared to other coupling types. This makes them ideal for hard-to-reach applications.

Custom N eupex couplings are commonly used in industrial applications where flexibility, misalignment compensation, and durability are essential for optimal machinery performance.

Mine and Quarry

In the mining and quarrying industries, Custom N eupex couplings are usually used to drive conveyors, pumps, and mobile equipment. Normally, they compensate for misalignment caused by vibration and heavy loads. This makes them a crucial component for maintaining reliable torque transmission in difficult environments.

Marine

Usually, N eupex couplings are used in marine engineering for boat engines. It dampens the transmission of torsional vibrations to protect the connected equipment from excess wear. Commonly found in shipbuilding and repair, these couplings ensure smooth and quiet operation in an otherwise harsh environment.

Chemical Processing

In the chemical processing industry, N eupex couplings work on agitators, mixers, and reactors. They are made from corrosion-resistant materials. Thus, this makes them ideal for transferring chemicals as well as other substances which may have corrosive properties to less durable materials. This offers durability and longevity.

Textile Industry

The textile industry heavily relies on N eupex couplings to operate machines. This ensures the smooth transmission of power with minimal vibration. Therefore, N eupex couplings are frequently installed in spinning, weaving, and finishing equipment to maintain fabric quality by reducing noise and shock.

Rubber and Glass Industries

In glass and rubber industries, N eupex couplings are known for their role in high-temperature applications. These couplings are commonly installed on machinery such as kilns and furnaces. Normally, they maintain torque transmission while absorbing thermal expansion stress. This makes them indispensable in these industries manufacturing processes.

Yes, CustomN eupex couplings can be tailored to specific application requirements. This is often in terms of size, material, and operational parameters. Such customization ensures optimal performance in particular niche environments.

Yes, they are suitable for high-speed applications. Additionally, they will require careful consideration of material selection.N eupex couplings must possess the requisite flexibility as well as superior strength to avoid coupling breakdowns.

The primary advantages are their flexibility, anti-corrosion properties, and minimal maintenance requirements. These advantages make them preferable in industries with quick vibrations and corrosive environments.

Normally, N eupex couplings require less maintenance. Often, periodic inspections for wear or damage are needed. This should be accompanied by lubrication checks to ensure optimal performance.

Occasionally, the primary limitation is their torque and load capacity. Usually, they are unsuitable for high-torque or heavy-load applications. Furthermore, these would require the use of heavy-duty or alternative couplings.