(2164 products available)

Mesh ramps are mobility solutions designed to facilitate the safe and efficient movement of wheeled traffic over vertical thresholds, such as curbs, doorways, or small inclines. These ramps are typically constructed from durable materials like aluminum or steel, featuring a mesh surface that provides traction and reduces the risk of slipping in various environments. There are several types of mesh ramps, each catering to specific needs and applications.

Aluminum Mesh Ramps

Aluminum mesh ramps are popular for their lightweight yet robust construction. They are easy to transport and set up, making them ideal for applications such as wheelchair access, mobility scooters, and hand trucks. The aluminum mesh surface offers good traction, while the raised edges prevent accidental wheel runoff. These ramps are available in various sizes and weight capacities to accommodate different needs.

Foldable Mesh Ramps

Foldable ramps are designed for portability and compact storage. They are often constructed from aluminum and feature a bi-fold or tri-fold design that allows the ramp to be folded in half or thirds. This feature makes them easy to carry in vehicles and convenient for various applications, including wheelchair access, loading equipment, and pedestrian access at events or construction sites. Despite their foldable design, these ramps maintain structural stability and weight capacity.

Heavy-Duty Mesh Ramps

Heavy-duty mesh ramps are engineered to handle substantial loads and are often used in industrial or commercial settings. These ramps feature reinforced construction and wider load platforms to facilitate the movement of heavy equipment, such as pallet jacks, forklifts, and industrial carts. The mesh surface provides excellent traction, while the ramps' durability minimizes wear and tear from frequent use.

Portable Mesh Loading Ramps

Portable mesh loading ramps are designed for easy transportation and setup, making them suitable for various applications, including truck loading, equipment transport, and industrial use. These ramps often feature safety straps that secure the ramp to the vehicle or loading surface, preventing accidental displacement during use. The mesh surface enhances traction, reducing the risk of wheeled traffic slipping. Portable loading ramps are available in various sizes and weight capacities to accommodate different loading needs.

Custom Mesh Ramps

Custom mesh ramps can be designed and manufactured to meet specific requirements, such as dimensions, weight capacity, and additional features (e.g, lighting or specialized surface treatments). These ramps are ideal for unique applications or environments where standard solutions may not suffice. Consulting with mesh ramp manufacturers can help businesses and organizations obtain custom ramp solutions that improve accessibility and safety.

Curbless Mesh Ramps

Curbless mesh ramps are designed without raised side edges, making them suitable for areas where wheel runoff is not a concern or where space is limited. These ramps facilitate seamless transitions over curbs or small thresholds, making them ideal for pedestrian access, bicycle lanes, and areas requiring barrier-free movement. The curbless design also promotes inclusivity for people with diverse mobility needs.

Weight Capacity

Each ramp comes with a specified weight capacity that shouldn't be exceeded. This is essential to prevent the ramp from collapsing or sustaining damage. In most cases, the weight capacity is determined by the construction materials used.

Size and Dimensions

Mesh ramps are available in different dimensions to suit various applications. The width and length of a ramp affect its usability. A longer ramp with a gentle incline is suitable for wheeling up an elevator, while a shorter one is ideal for loading cargo into a truck.

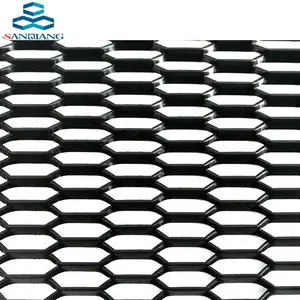

Surface Texture

Mesh ramps come with different surface textures, such as raised patterns or abrasive coatings. The surface texture affects traction and slip resistance. Ramps with rough surfaces offer better grip and are ideal for steep inclines or wet conditions.

Size and Dimensions

Mesh ramps are available in different dimensions to suit various applications. The width and length of a ramp affect its usability. A longer ramp with a gentle incline is suitable for wheeling up an elevator, while a shorter one is ideal for loading cargo into a truck.

Surface Texture

Mesh ramps come with different surface textures, such as raised patterns or abrasive coatings. The surface texture affects traction and slip resistance. Ramps with rough surfaces offer better grip and are ideal for steep inclines or wet conditions.

Folding Mechanism

Folding mesh ramps come with different folding mechanisms. Some have multiple sections that fold up, while others have a bi-fold or tri-fold design. The folding mechanism affects portability and ease of storage.

Follow these steps to maintain mesh ramps:

Choosing the right mesh ramps can be a difficult task. Buyers have to consider several factors to ensure that they get ramps that will meet their needs. Here's a guide to help them choose the right mesh ramps:

Weight Capacity:

When buying a ramp, it's important to check the weight capacity. This is the maximum load the ramp can carry without bending or breaking. Make sure to choose a ramp with a higher weight capacity than the combined weight of the vehicle and the cargo. Using a ramp with a lower weight capacity can be dangerous and will cause the ramp to get damaged over time.

Length and Angle of Incline:

The length of the ramp affects the angle of incline. For buyers to choose the right length, they need to consider the height of the load they want to use the ramp on. A longer ramp will have a more gentle incline, making it easier to load and unload heavy items. Shorter ramps are more portable but difficult to use on higher surfaces.

Material and Durability:

Buyers should choose ramps made with durable materials that can withstand regular use and the weight of the vehicle. Common materials for ramps are aluminum and steel. Both are strong and have a lightweight property, which makes them portable. They also differ in other features. For instance, mesh ramps made with aluminum have higher corrosion resistance than those made with steel.

Safety Features:

Buyers should look for ramps that have safety features to prevent accidents. These features include raised edges to prevent the vehicle from slipping off the ramp and surface grips for traction, which reduces the risk of slipping.

Portability and Storage:

Buyers should consider how they want to transport and store the ramp. If they want to use the ramp for camping or other outdoor activities, they should go for lightweight and foldable ramps.

Price:

Buyers should set a budget for the ramp they want to buy. However, they need to consider the value of the ramp in relation to its cost. The most expensive ramp is not necessarily the best, and the least expensive ramp may not meet their needs.

Most mesh ramps are easy to install and replace. The following steps offer a general guide on how to DIY and replace mesh ramps:

Is mesh better than solid ramps?

What are the advantages of a mesh ramp?

Do people use mesh ramps for loading motorcycles?

Can a mesh ramp be used for heavy equipment loading?

How do mesh ramps compare to traditional aluminum ramps?