(7850 products available)

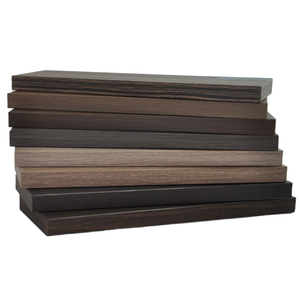

MDF sheet E1 E2 is a medium density fiberboard that is used in construction and carpentry. It is a board made from wood fibers glued together with resin under heat and pressure. The MDF boards are then cut into different sizes and used for a variety of applications. The E1 and E2 in the MDF sheets refer to the emission levels of formaldehyde, which is a chemical used in making the MDF boards.

There are different types of MDF boards based on their usage. They include:

When examining E1 and E2 MDF sheets, it is important to understand their features and functions. Here is a breakdown.

Uniform Surface

The main feature of MDF is its smooth surface. MDF is designed to be an even, flat board without imperfections, knots, or grain texture. This helps when applying coatings, as they stick better to the smooth surface and provide a more attractive finish.

Thickness

MDF sheets come in varying thicknesses. The thickness of the MDF sheet influences its use as a building material. Thin sheets are appropriate for applications requiring little structural integrity, like backing on cabinets. Thicker sheets are better for projects that need more strength, like tabletops or drawer fronts.

Edge Binding

Edge binding is a feature of MDF sheets that helps the edges look better. Edges can be bound using veneer or PVC. Binding the edges of the MDF sheet ensures that the final product looks good, no matter what application it is used for. It also helps to prevent fraying and improves the strength of the edges when using glue to attach them to other surfaces.

Moisture Resistance

While standard MDF sheets are not resistant to moisture, E2 MDF sheets have been designed to resist it. Their surfaces have been treated with special chemicals that help to prevent moisture from being absorbed. This helps to stop the problems that moisture can cause, like warping and swelling.

Easy to Work With

These sheets of MDF can be cut, shaped, and drilled easily. This makes them a popular choice for people who want to make things in their workshops. They can be made into many different things without much trouble.

Cost-Effective

MDF sheets are generally cheaper than other wood products. This makes it possible for more people to use them. Whether a professional carpenter or someone who just likes to work with wood, using these sheets means spending less money.

Easy to Paint

The smooth surface of the MDF sheets makes it easy to paint them. If a project requires parts to be painted different colors, MDF is a good choice. The paint goes on smoothly and doesn't run, so the finished product looks nice.

There are many scenarios where MDF sheets are used, and they include:

Furniture Construction

MDF is commonly used in building cabinets, dressers, and other storage furniture. Its smooth surface makes it ideal for building painted furniture that needs a sleek, modern look. Additionally, due to its stability, the MDF board is less likely to cause issues with the alignment of the doors and drawers.

Built-in Furniture

These sheets are used to make built-in furniture like bookcases, window seats, and entertainment units. Using MDF for these projects allows a customized solution that integrates seamlessly with the space. The ability of MDF to be tailored into complex designs makes it ideal for intricate built-in furniture, such as those with detailed moldings or paneling.

Decorative Wall Covering

These boards are used to create feature walls with paneling, wall art, and other custom wall coverings. Their smooth surface, which is painted or textured, enables them to create stylish and modern wall coverings. Additionally, these boards are customizable, enabling the construction of intricate designs, such as geometric patterns or elaborate moldings.

Soundproofing

These sheets are used in acoustic panels, room dividers, and soundproofing walls. They make sound-absorbing panels that are lightweight and easy to handle. Additionally, the smooth surface of these sheets allows the attachment of fabric or other porous materials. Moreover, these panels are used in concert halls, theaters, recording studios, and other spaces that need sound control.

Crafting and Hobbies

These boards are used in various projects, including model building, miniature furniture construction, and customized decorative items. They are popular among hobbyists and crafters because they are easy to work with. Additionally, they allow the creation of precise and detailed models because they are uniform and dense.

Door Manufacturing

MDF is widely used in making internal doors, especially hollow-core doors. These sheets are also used to make decorative doors, such as those with panels or molded frames.

When choosing E1 or E2 MDF sheets, consider the following factors:

Emissions

Emissions levels are crucial when choosing between E1 and E2 MDF sheets. Look for products certified with emission levels. Such sheets are safer for human use and conform to international standards. Choose E1 sheets for projects requiring lower emissions. E2 sheets are suitable for projects where emissions are not a primary concern.

Environmental Standards

Consider the environmental standards in the area. In some areas, E2 standards are more applicable than E1. Find out which standards are applicable before choosing the sheets. This ensures compliance with local regulations.

Intended Use

Intended use is another primary factor to consider. Choose E1 sheets for uses that require lower formaldehyde emissions. Such uses include furniture, cabinetry, and interior applications. Select E2 sheets for applications where emissions are not a primary concern. Such uses include construction projects and non-residential settings.

Budget

The budget significantly influences the choice between E1 and E2 MDF sheets. Generally, E2 sheets are more affordable than E1 due to the difference in production processes and chemical treatments. A limited budget may necessitate the use of E2 sheets. However, it is important to note that spending more money on E1 sheets may offer long-term savings. For instance, in projects where higher quality and lower emissions are required.

Availability

The last factor to consider is the availability of the sheets. Occasionally, specific grades may be more accessible depending on the location and supplier. Check the local suppliers' stock to find out which grade is available. This will help to facilitate faster project completion.

Q1: What are the applications of E1 and E2 MDF sheets?

A1: E1 and E2 MDF sheets are applicable in various uses. E1 sheets can be used in construction projects, furniture making, and decorative projects. E2 sheets are suitable for applications where formaldehyde emissions are not a concern. Such applications include furniture making, crafts projects, and decorative projects.

Q2: How can one distinguish between E1 and E2 MDF sheets?

A2: It is possible to differentiate E1 from E2 MDF sheets by examining their edges. The edges of E1 sheets are usually smooth and uniform, whereas those of E2 sheets may show signs of roughness or irregularity. Additionally, one can conduct a formaldehyde test using a test kit.

Q3: Are E1 and E2 MDF sheets eco-friendly?

A3: E1 and E2 MDF sheets are as eco-friendly as possible. They are manufactured using wood by-products that would otherwise go to waste. Additionally, these sheets are recyclable.

Q4: What does E1 mean in MDF?

A4: E1 is a term used to describe MDF sheets with low formaldehyde emissions. These sheets are safer for use in indoor applications.

Q5: What does E2 mean in MDF?

A5: E2 describes MDF sheets with slightly higher formaldehyde emissions than E1. These sheets are more suitable for use in applications requiring high levels of durability and moisture resistance.