(1455 products available)

Potato Washing and Peeling Machine

The workflow of a potato-washing-and-peeling machine is rather simple. Usually, it comprises a torus with a guarantee to scuff and a component with no-upkeep peeling system, like a lye solution or abrasives. A few machines even integrate ultra-high-g washing jets to get rid of all residue and contaminants fast.

Lays chips machinery is utilized to ensure appropriate excursion and get the high-quality result. Large lots can be processed in a brief timeframe, enabling the instant of excessive yields without straining personnel.

This apparatus is designed to address the excessive call for bulk potato processing. In some instances, washing and peeling can be finished in minutes to satisfy excessive commercial enterprise needs. The desire of cleansing and peeling technique relies upon the kind of potato and preferred lay's chip texture.

Slicing Machine

Slicing machines for Lay's chips use big, cylindrical, and sharp blades to make certain even slicing. Cables can likewise be equipped with one-of-a-kind blades to trade the thickness of the slices, which impacts the stop product's texture.

The device has to be swift to offer the right yield without overloading. With the right slicing machine, clients could gain steady chip quality, which is crucial for customer satisfaction and the organization's achievement.

The slicing gadget attracts clients searching for adaptability and performance. The machine gives corporations the choice to trade chip thickness, increasing format options. It is important for operations that want to preserve pace with altering marketplace trends or consumer choices.

Frying Machine

The frying gadget for Lay's chips is designed to achieve best frying temps and lessen oil absorption. Lay's frying machines employ convection currents or oil flow to ensure even warmth transfer and fry the chips correctly.

The system must preserve a stable temperature in large businesses to keep the chip texture and flavor unchanged. Good frying machines have filtration systems that eliminate contaminants from the oil to be re-used and maintain the healthiest choice viable.

The frying device is vital because it affects the chip's taste, texture, and shelf existence. It permits clients to provide a similar high-quality product. Large potential frying machines satisfy industrial frying necessities while also renovating oil faster and extra correctly.

Dehydration Machine

The dewatering device uses heated air to eliminate moisture from the chips, enhancing crispness. Lay's chips dewatering machines use low-humidity air at excessive speeds to cover the chip's surface and boom shelf stability.

The air change price and temperature manipulation are important characteristics that have to remain stable to make certain that the chips reach the right moisture content material. Customers running the device have the ability to extrude the conditions for dehydration, allowing them to alter the chip texture to fit one-of-a-kind taste profiles.

The dewatering device is essential for growing lay's longer-shelf-existence chips. It reduces moisture content to save spoilage and allows chips to stay crisp longer. This is specifically beneficial for mass distribution and lengthy garage periods.

Baking Machine

A baking system uses hot air to cook Lay's chips with less oil, growing a fitter alternative. Lay's chips baking machines flow warm, humid air across the chips to prepare dinner uniformly and remove moisture.

The system's design guarantees that warmth and humidity flow possibly to come back into touch with every factor, generating a uniform bake. Precise temperature controls allow the user set the baking profile for every type of chip.

The baking device is critical for consumers trying to provide a more healthy, lower-fat product. It is an opportunity to frying, imparting a crisp texture without the added oil. The device is perfect for customers searching out more healthy alternatives to provide to their customers.

High Capacity and Efficiency

Industrial frying machines for Lay's chips are made to offer high frying outputs while lowering time and exertion. Its capacity and efficiency are critical elements that impact processing potential and the level of restocking required in a business putting. Large-capacity machines can fry massive quantities of chips quickly, keeping the product's first-class and meeting commercial enterprise dreams. One of the important requirements while deciding the functionality of huge frying machines is the frying ability in keeping with the hour.

Industrial-size machines are commonly engineered to manage high masses and make sure the process maintains even beneath remarkable instances. Large-capacity devices are important for assembly calls for in peak times without causing delays in processing or refusal to provider clients.

Consistent and Uniform Results

Homogeneity is vital for Lay's chips because they need to have a comparable texture, taste, and look in every batch. Advanced warmth distribution systems in large-capacity frying machines for Lay's chips ensure that each factor of the chips is cooked calmly and to the identical degree.

Consistent results are critical for preserving products' great and assembly buyer expectations. Companies can harvest uniform chips constantly without manual tweaking or adjusting if they have advanced sensors and controls that preserve steady temperatures and moist ranges.

Uniformity reduces waste by ensuring that chips do not return at a subpar quality. Large-capacity gadgets offer flexibility for companies to provide constantly high-quality food in numerous circumstances, from commercial enterprise to seasonality.

Advanced Control Systems

State-of-the-art manage structures are vital in large-capacity gadgets, considering the precise manipulation of fry temperatures, moist levels, and processing instances. The chips can gain the quality sought by using imparting operators with a properly smooth-to-use tool panel to peer and alter those factors in real time.

These management systems allow companies to fulfill various layout specifications for disorder or specific chip textures. Sensors and alarms that trade proprietors if something goes incorrect during meals processing stop costly downtime and waste.

Large-capacity machines with today's manipulate structures attract businesses looking for a greater product and more distinctive overall food enterprise solution. These businesses will gain a stronger alignment between processing potential and meal best.

Auto Filtration System

The vehicle filtration machine is one of the most important developments in a big frying system's capability and sturdiness by using preserving the oil most effective longer. Remove pollutants and particles from the oil to enhance the flavor and great of the chips; automatic filtration systems frequently cycle the oil through diverse filters or give up traps that accumulate debris.

It Saves destitute and reduces the time spent exchanging oil by using vehicle filtration. It allows processing to hold longer without replacing the oil by using preserving the oil purer. Keeping oil easy is likewise essential for preserving the fryer's components from harm and extending the system's existence. Companies anticipate that large-capacity frying machines will include car filtration systems because they improve working efficiency and labor fees.

Assess Business Needs

Before selecting the gadget, businesses want to determine their scale and capability dreams. This entails deciding what kind of chips they'll make, how plenty they will provide, and what exceptional requirements they have.

By using assessing crucial commercial enterprise desires for lays chip gadget, purchasers can also accumulate a system that meets operational necessities and contributes to productiveness. It's a strategic method that complements performance and profitability by considering potential, consistency, and meals processing needs.

Slicing and Frying Capabilities

Considering the slicing and frying functions of the device is important since it appreciably impacts the final product's great. The slicing system must offer flexibility in chip thickness to accommodate one-of-a-kind recipes and patron alternatives. At the identical time, the frying potential have to be sufficient to satisfy manufacturing dreams whilst preserving a steady texture and flavor.

Consistently excessive-carry-out frying structures with homogenous warmth can achieve ideal frying outcomes. Companies can ensure that the tools can produce Lay's desired chip excellent by comparing the frying and slicing skills.

Durability and Maintenance

Another essential thing of choosing lays chip equipment is system sturdiness and renovation. Heavy-responsibility substances and a sturdy design for the business may want to face as much as many years of steady use. Businesses also want to keep in mind the upkeep requirements of the system; everyday inspections and smooth servicing can significantly enhance its lifetime.

In Commercial cooking, general substitution can charge an entire commercial enterprise, so the device ought to be sturdy. Customers can also choose merchandise that could resist extreme frying and washing environments. Ensuring the commercial enterprise has a sturdy device reduces downtime and grows return on investment.

Energy Efficiency

Large frying machines for Lay's chips are deigned to be energy efficient because expenses for strength use over the long term can climb very steeply. Assessing the strength efficiency of the device can lessen functioning expenses appreciably without compromising overall performance.

Because energy charges can mount dramatically with frying machines, large-capacity commercial enterprise customers will particularly gain using power-green machines. By choosing an electricity-environmental-friendly selection, groups can store money, lessen their environmental results, and ultimately offer a practical solution to running costs.

Customer Support and Warranty

When making an investment in lays chip system, businesses must recollect the producer's purchaser aide and guarantee. A reliable guarantee can provide insurance in case of system inadequacy and offer the alternative to behavior positive maintenance and restoration with no out-of-pocket value.

A expert patron aide may want to assist with troubleshooting and education. Businesses can experience greater relaxed of their funding, understanding that they will get support while required, with guarantees and robust patron assistance.

Large-Scale Production

Lay's chips system allows satisfactory large-scale manufacturing run of chips according with the desired exceptional and texture. Because of its large capacity, it may process extra potatoes in much shorter instances, making it best for big producers.

The appliance's potential to speedy and correctly produce chips at scale satisfies industrial requirements and maintains offers in stores. The range of commercial system transient clients and clients can currently deal with by using mass-producing chips.

Snack Food Industry

The Lay's chip equipment is crucial for the complete treat-making industry, along with bottling and different chip-makers. It guarantees the constant, prime best, and mass output required to fill retailer cabinets and industrial distributors.

The equipment works properly with different club pack sizes and flavored options. Businesses can use adaptable gadget to maintain marketplace competitiveness and conquer call concerns inside the snack food space.

Custom Chip Production

Lay's chip system can also make chips with customized tastes and textures. Thanks to adjustable slicing thickness and cooking settings, companies can tailor the gadget to particular demand, enabling the introduction of one-of-a-kind recipes or niche gadgets.

This flexibility allows corporations to offer innovation and personalize items to satisfy consumer requirements. With the gadget in place, even the maximum weird concept can scale manufacturing to meet the call. Companies can distinguish themselves in the industry by offering specialized chip goods.

High-Volume Retail Operations

Retail establishments with baked chip stations or snack kiosks can gain from having the Lay's chip device available. High-volume retail settings depend on the system to maintain a steady supply of freshly cooked or organized chips to meet patron wishes.

The appliance's commercial potential guarantees that it can produce a distinguished product swiftly and with a consistent process to preserve purchaser content. It is a should-have component for retail environments that desiring-loving offers to clients straight away.

Food Service Operations

It can be used for food vehicles, eating places, and concessions that provide chips with the Lays chip gadget. For clients with high desire loads, business objectives require the gadget to create a prime product speedy without compromising quality.

Thanks to customizable cooking settings, food provider groups can offer a huge type of chip textures and flavors. Customers can keep a steady supply of a well-awaited appetizer with proper device in location.

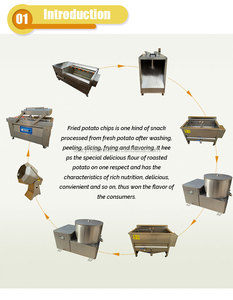

The fundamental factors of Lays chip machinery are as follows. They encompass washing, peeling, slicing, frying, and dewatering, which are the methods of processing the substances. Pack and season the gadget to preserve quality whilst presenting flavor and crunch.

The factors of the system are made to manage large masses efficiently while preserving the chips' texture and flavor. Companies can produce a consistent and excessive best product by integrating those strategies.

Businesses ought to examine the processing skills of the gadget, the exceptional components, and the price. Growing chip production can put a strain on a business if it's too small to address call for it. One cannot underestimate great attention because it significantly impacts consumer satisfaction.

Lastly, commercial enterprise charges can be decreased with a value-efficacious answer. To pick the suitable gear that guarantees unhindered operations and product best, businesses need to weigh those elements against every other and examine them.

The Lays chip device is rather adaptable and could deal with distinct, unique chips, including herbal, spicy, and candy tastes. Because the slicing and cooking settings are adjustable, one equipment can easily manage a plethora of textures and flavors.

Companies can gain a competitive benefit by producing precise or seasonal merchandise to satisfy consumer requests. Retailers and food service operations are specifically attracted to the adaptability of the tools for personalized manufacturing.

Lays chip manufacturing unit device is constructed from strong industrial materials to resist continuous use. Regular inspections and post-processing of residuals are a few habitual upkeep techniques businesses can use to keep the device running properly.

The truth that many components can be taken out and serviced makes upkeep easier. Businesses can reduce downtime and grow production through investing in sturdy, smooth-to-repair gadgets.