(1521 products available)

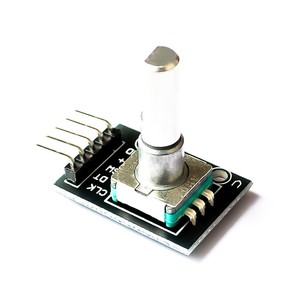

I2C rotary encoders can be of several different types.

It's common for manufacturers to employ multiple encoding mechanisms. Each one is tailored to diverse application requirements.

The following are the most popular types.

Absolute encoders extract a unique position value from a rotational pattern.

This creates a specific position code for each angle of rotation. This makes these encoders ideal for tasks.

These tasks involve keeping close track of motor shafts or robotic joints. This is because they can return a precise absolute position even after a power cut.

This feature offers a dependable fallback for missions requiring constants.

The constants are things such as homing or configuration.

Incremental encoders are effective at recognizing and counting rotational movements. This functionality makes them appropriate for measuring motion.

Motion parameters include speed and direction in motors.

They generate output signals using two tracks. These tracks are out of phase. The phase shift indicates the direction while the number of pulse denotes the rotation extent.

Unlike absolute encoders, incremental ones keep no inherent positional data.

This means that after a power loss, they must be reset.

Multi-turn encoders unite the characteristics of both absolute and incremental designs. They record the number of turns apart from the angle of rotation.

The outcome is a comprehensive positional data set usable in tasks requiring multiple rotations.

Such tasks usually are in mechanisms with extensive rotational ranges like robotic arms. These arms need an extensive range of motion for operation.

Durability and robustness are key factors when choosing such encoders. That's because their construction influences not only their lifespan but also their precision and reliability.

The casing of these encoders generally makes use of aluminum or reinforced plastics.

This is to provide a reasonable mix of ruggedness and weight.

Incremental encoders need thick metal drive shafts to ensure good performance. These shafts are often machined from stainless steel or other solid metallic composites.

Steel's resistance to wear and corrosion guarantees that the encoder manages high loads and stays functional in hostile surroundings.

Absolute and multi-turn designs frequently incorporate gears or other transmission elements within their encoders.

These are commonly composed of high-strength plastics or light-alloy materials.

These materials endure wear, maintain efficient operation for prolonged periods, and minimize noise during functioning.

With the expounding above, it can be noted that I2C rotary encoders find broad use across various commercial sectors. These sectors include robotics, industrial automation, and consumer electronics.

They provide high accuracy and seamless integration. These qualities make them a preferred choice in numerous applications.

These encoders play a vital role in enhancing the operational precision of robotic systems. The systems can be either simple or complex.

They accomplish their task by providing detailed feedback on the position and movement of robotic limbs.

This feedback is especially useful when used in automated assembly lines or service robots.

This feedback then aids motion control.

This not only improves accuracy but also increases efficiency and cutting down energy consumption.

The utilization of I2C also simplifies wiring. So, it becomes ideal for compact or tightly spaced systems like desktop automation robots.

These encoders are used to monitor motor shafts and other rotating components in this space. They allow systems to determine speed, direction, and precise angular positioning.

For instance, in conveyor systems, they can adjust the belt speed based on the load.

This then optimizes throughput and prevents system overloads.

In servo motors, these encoders enable closed-loop control systems. This control keeps the motor at the desired position, enhancing reliability in machinery.

The encoders are commonly used in adjusting device controls like volum knobs in audio systems. They also serve as joysticks in gaming consoles and cameras for smooth precise input.

Providing accurate positional feedback then enhances user interaction. This improvement results in a more fluid experience.

The encoders are then integrated into devices that require compact designs. These designs include smartphones and tablets.

Thus making them suitable for devices where space is limited but functionality is still essential.

It's crucial to consider several key factors to select the right I2C rotary encoder for a given project. These factors include the application requirements, type of the encoder, and environment operating conditions.

These choices should be guided by the general use of the product.

High resolution and accuracy are key requirements in various applications. Such applications include robotics, automation, and precision control systems.

These systems favor absolute I2C rotary encoders with several positions. This number of positions is typically in the thousands.

On the other hand, industrial equipment may perform sufficiently with encoders having lower resolutions.

These low-resolution encoders typically possess several positions in the hundreds.

When selecting these encoders, how harsh the environment will be should also be considered. Take for example, in outdoor or extreme environments like factories and construction sites.

It's important to have an encoders that are rated IP67 or higher.

In addition to this, opt for a solid housing design that prevents water, dust, and debris from entering the device.

You will also have to consider which type of encoder best meets the application demands. Absolute encoders are commonly suitable for tasks that require knowledge of position at all times.

As previously mentioned, such tasks may include automated machinery homing procedures. On the flip side, incremental encoders may be sufficient for applications where the power is not likely lost.

Multi-turn encoders are useful for any application requiring multiple rotations. They also need position feedback for every rotation.

A. These encoders convert rotational motion into digital signals. These signals are then used to keep track of angular position, speed, and direction. They are mostly used in robotics, industrial automation, and consumer electronics.

A.The devices include motors, robotic arms, joystick interfaces, and camera lenses. In addition to these, they are also used in control systems for electronic music instruments.

A.I2C is a popular communication protocol. This popularity comes from its simplicity and ability to support numerous devices on a single bus. Moreover, it requires minimal wiring, thus making it a go-to protocol for devices with limited space.

A. Unlike analog encoders, which provide a continuous voltage signal, these encoders offer discrete digital signals. These digital signals improve precision, reduce noise, and simplify data processing.

A. Yes, many industries have a favorite type of these encoders. For instance, the electronics industry favors incremental encoders. It is because they are particularly good at simple tasks that don’t require too many circuits.