(418 products available)

High-speed HSK

The HSK tool holder has a spilt collar design. The tool holder and spindle have a positive machine fit, improving runout and stiffness. HSK toolholders are also self-locking. When a driving key or pin fits into the toolholder, it forces the toolholder collar tighter around the spindle. The clamping force increases with the opposite force on the cutting tool.

High-speed HSK50A CNC Tool Holder

A variant of the A is the A+, which has a larger diameter, increases axial load, and improves tool support. All HSK tool holder variants have A, D, or E collages. The A collage has a high friction tool joint that improves the grip between the tool joint and holder.

HSK40/50/63/80 CNC Tool Holder

The number after HSK refers to its taper size. HSK40 is suitable for small machining centers, while HSK80 works well on large machines. The HSK50 taper can hold small to medium-sized cutting tools.

HSK50 is ideal for high-load applications like aluminum alloy, stainless steel, and carbon steel. It improves the stability of tools like face mills and deep hole drills. Using an HSK50 spindle can minimize axial displacement when machining at high speeds.

Common HSK Tool Holders

Common HSK tool holders include HSK milling holders, HSK boring bar holders, and HSK adjustment and coupling sleeves. HSKE coupling sleeves connect dissimilar spindle and toolholder tapers. Adjustment sleeves enable holders with a smaller taper to fit into an HSK spindle. A boring bar has a long holder that makes deep internal cuts.

Specifications vary depending on the specific type and brand of the HSK50 CNC tool holder, but generally, the following factors may be given.

Maintenance is mostly straightforward. It entails cleaning the tool holder, checking for damages, lubricating moving parts, or storing it correctly when not in use.

Industry: Automotive

Application scenario: A professional HSK50 CNC tool holder is applied in the automotive industry to cut and trim car bodies and frames.

Industry: Aerospace

Application scenario: The Aerospace industry employs tools like HSK50 CNC tool holders to help create aircraft components like wings and fuselage.

Industry: Woodworking

Application scenario: In the woodworking industry, an HSK50 CNC tool holder can be used with routers and other CNC machines to carve intricate designs.

Industry: Metalworking

Application scenario: The HSK50 CNC tool holder is widely used in the metalworking industry. In this case, it works with mills to cut metal materials.

Industry: Packaging

Application scenario: In the packaging industry, an HSK50 CNC tool holder can be used with CNC machines to cut packaging materials and make customized molds.

Industry: Medical Devices

Application scenario: Based on Medical devices industry requirements, an HSK50 CNC tool holder is capable of machining complex medical device components. For example, it can be used to make surgical instruments and implant devices with precise detailing.

Industry: Rapid Prototyping

Application scenario: The Rapid Prototyping industry often uses HSK50 CNC tool holders to help create prototype models and test parts quickly. It provides flexibility and precision for the product development process.

Many factors need to be considered before deciding to purchase HSK tool holders for CNC machines. These include the following:

Machine Compatibility

When choosing an HSK tool holder, it's essential to consider if it matches the CNC machine. The tool holder will only work well if it fits the machine's design. This means it will connect nicely and function as it should.

Quality Materials

How well a CNC machine tool holder works and lasts depends a lot on the materials it's made from. High-quality materials make the tool holder strong and able to endure heavy use and resist wear. They also help it withstand higher temperatures and prevent any possible chemical reactions.

Gripping Mechanism

The choice of an HSK tool holder may also depend on the gripping mechanisms available. This includes the types of collets or chucks used in the holder. Select an HSK tool holder with a gripping system that matches the required level of precision and stability. Also, consider the collets' versatility and compatibility with various tools.

Tool Variety

An HSK tool holder may suit some specialized tools better than others when considering the range of tools used. Larger diameter tools may need an HSK f50 tool holder to provide the required rigidity and support.

Retaining Ring

Retaining rings are used to hold the tool strongly within the tool holder. They also aid in the quick release of the tool holder whenever it's necessary. Different CNC machines use different types of retaining rings according to the design and specifications. Selecting an appropriate retaining ring for the specific HSK tool holder is very important for ensuring effective operation and tool stability.

Balance

It is imperative to select tool holders that have an excellent balance. A balance tool holder ensures that forces are uniformly distributed throughout the holder while it spins. This minimizes the wear and tear on the rotating parts and helps to prevent any possible damage to the CNC machine.

Q1: What machines use HSK tool holders?

A1: HSK tool holders are common in high-speed CNC milling machines and machining centers designed for precision and efficiency benefits.

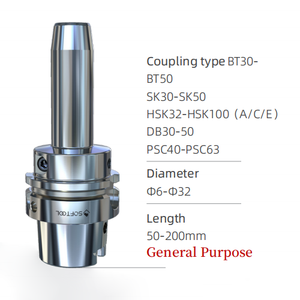

Q2: How does HSK compare to BT tool holders?

A2: While both outer taper tool holders, like the HSK50C, HSK40A, and HSK60A tool holders, are designed to fit and work with similar cutting tools, the HSK tool holder has better clamping force and tool release, and it usually offers superior performance in high-speed applications compared to the BT tool holder. This advantage is mainly due to the straight shank HSK tool holder's integral feature, which facilitates a more precise snug-fitting projection.

Q3: Can HSK tool holders be used in other 쎈툴 홀더들?

A3: Using HSK tool holders in other tool holder types is not recommended. This is because it might affect the tool's performance, compromise machining accuracy, and sacrifice safety.

Q4: Can an HSK tool holder fit an HSK taper?

A4: While HSK tapered holders are manufactured to precise specifications, it's still safer and better to use HSK tool holders that are made by the same manufacturer as the HSK taper. This way, it'll help maximize performance and ensure adequate tooling.