(4047 products available)

A hose shrink is a type of fitting used to connect hoses. It's also known as a hose barb. The hose shrinks fits onto the tube or hose and is crimped or soldered onto the other end. The design of a hose shrink fitting allows fluid or gas to pass through it efficiently. There are several types of hose shrinks, including the following:

Barbed Hose Shrink:

This type of hose shrink has little barbs or teeth that grip the hose when pushed over it. It is a slip-on design that is perfect for low-pressure applications. The user can apply hose clamps to the barbs to make a more secure connection. Barbed hose shrinks are inexpensive and easy to install. They are perfect for applications like coolant or fuel lines. The barbs create a mechanical bond and seal with the help of clamps.

Bevelled and Flared Hose Shrink:

The flared hose shrink features a 45-degree angle lip that helps the fitting guide the hose over it for crimping. It provides a strong, reliable connection that can be used for high-pressure applications. The beveled hose shrink has a tapered design suitable for crimping or soldering. Both of these fittings are commonly used in hydraulic applications and provide a high-pressure seal. They require special tools for installation but have low flow resistance.

Barrel and Swivel Nut Fitting:

The swivel nut fitting has a nut that rotates around the fitting while the hose stays in the same position. This design makes it easier to tighten connections in tight spaces. The barrel fitting is non-swiveling and requires precise alignment during installation. Both of these fittings are used for connections that need to be easily removed and reattached. They are popular in pneumatic and hydraulic systems.

Compression and Threaded Shrink Fitting:

The compression hose shrink fitting uses a ring and nut to compress the hose onto the fitting, creating a seal. This design is easy to install and remove, making it perfect for applications like plumbing. The threaded hose shrink has internal or external threads that allow the hose fitting to screw onto the hose. It creates a strong, leak-proof connection that can be easily replaced but requires precise machining.

Hose shrinking entails utilizing heat to make hoses fit more securely over connections. These are some of the functions and features of hose shrinks:

Heat Generation:

The key feature of a hose-reducing tool is its ability to create heat. The heat causes the expanded tubing to shrink and fit tightly over the barbed fitting or connector. This creates a more secure connection that helps the hose withstand higher pressure without leaking.

Controlled Temperature:

The hose-reduction tool is designed to ensure the heat is controlled. This is crucial when working with hoses. The temperature needs to be just enough to cause the tubing to shrink without overheating or damaging the hose material. Too much heat can weaken the hose or cause it to melt. So, the tool has a way of regulating the temperature to ensure it is constant and safe for use.

Safety Features:

The hose-shrinking tools have built-in safety features. They ensure operations run smoothly without incidents. For example, the tool may have automatic shut-off mechanisms. This prevents overheating. Others may come with insulated handles. They protect users from accidental burns.

Portability:

The hose shrinking tools are lightweight and easy to carry. This makes it convenient for use in different locations. A user can easily transport it to a workshop or job site without struggling.

Versatility:

These tools can be used in different applications. It can be utilized in marine, automotive, and industrial settings. This makes it a preferred tool among many users.

Ease of Use:

The hose-shrinking tools are simple and straightforward. They come with instructions on how to operate them effectively. Following the guidelines, users can reduce hoses safely and efficiently.

Durability:

These tools are made with strong materials. For example, most of them are constructed with high-quality aluminum and steel. This ensures they can withstand harsh working environments. It also guarantees longevity and reliability.

Hose shrunks offer a variety of applications across different industries and sectors. Here are some common scenarios where hose shrunks are used:

Automotive Industry

Hose shrunks are used to cover wires and hoses in the engine compartments of vehicles. This helps to provide a clean look and protection against abrasion. They are also used in the customization of wire harnesses and thermal management systems. This helps to improve the functionality and ensure the aesthetics of the automotive electrical systems.

Aerospace

Heat shrinkable tubes are used in the aerospace industry for wire harnesses and cable assemblies. This is because they provide a lightweight solution for aircraft and spacecraft. They are also used in the protection of high-temperature cables and components in the aerospace industry. This ensures the reliability and safety of the aircraft operations.

Electronics and Electrical

Hose shrunks are used in the insulation and protection of connectors, splices, and wire ends. This helps to prevent short circuits and reduces the risk of electrical fires. They are also used to provide strain relief and prevent mechanical stresses in electronic and electrical devices.

Consumer Electronics

These products are used in the internal wiring and cable management of electronic devices. This includes smartphones, laptops, tablets, and other electronic gadgets. Hose shrinks are popular in these devices due to their lightweight and compact design. This enhances the portability and convenience of these devices.

Marine

Hose shrunks are used in the protection of wires, cables, and hoses in marine environments. They provide resistance to UV and water, which promotes the reliability of the electrical systems. Hose shrinks are also used in the prevention of abrasion and marine growth on wires and cables in boats and ships.

Home and Industrial Applications

These products are commonly used in electrical wiring for homes and industrial setups. They are used to insulate and protect wires, preventing electrical shocks and short circuits. Additionally, they are used in the repair of damaged wires and provide a neat finish in electrical wiring.

When looking for a heat shrink for hoses, there are several factors to consider. Here are some of them:

Durability and Material

When choosing a hose shrink, it is important to consider the material and its durability. One should select a material that can withstand harsh environmental conditions and high temperatures. Also, select a durable material that won't wear out quickly.

Heat Resistance

When selecting a hose shrink, choose one that can withstand high temperatures without collapsing or getting damaged. This is important for hoses exposed to high temperatures during operation.

Flexibility

Choose a hose shrink that is flexible enough to allow easy installation on curved or bent hoses. A flexible hose shrink will provide a smooth finish and maintain its integrity when the hose is under pressure or stretched.

UV Resistance

For hose shrinks used in areas that are directly exposed to sunlight, it is important to choose a heat shrink that is UV resistant. UV-resistant heat shrinks will prevent any damage or degradation due to prolonged exposure to sunlight.

Check Compatibility

The heat shrink should be compatible with different types of hoses. This is important for various applications, such as fuel, water and air hoses. Compatibility ensures optimal performance and prevents any leakage or damage.

Size and Diameter

The heat shrink must be the right size to fit over the hose. It is also important that the heat shrink diameter expands to fit over any connectors or fittings attached to the hose. This ensures a tight seal and prevents any leaks.

Expansion Ratio

The hose shrink is used to cover different types of hoses. The heat shrink has an expansion ratio used to calculate the size of the hose when the heat shrink is expanded. Choose a heat shrink with an expansion ratio that conforms to the hose size.

Ease of Installation

When choosing a hose shrink, select one that is easy to install. This reduces the cost of labor and time spent working on the project. A heat shrink that is difficult to install properly reduces its efficiency and can cause damage to the hose.

Vendor Support

When choosing a hose shrink, it is important to consider the vendor support. Choose a vendor who is willing to provide technical support and answer any questions that arise while using the product.

Q1: What are the common applications of hose shrink?

A1: Hose shrinks are used in various applications, including automotive wiring, marine electronics, industrial machinery, and consumer electronics. They are also commonly used in parts requiring cable and wire harnessing, such as motorcycles, airplanes, and appliances.

Q2: What are the benefits of hose shrinks?

A2: Hose shrinks offer various benefits, including environmental protection, mechanical support, and enhanced aesthetics. They also provide improved electrical insulation, reduced signal loss, and increased durability. Additionally, hose shrinks offer seamless installations and improved heat dissipation.

Q3: What factors should be considered when choosing a hose shrink?

A3: Consider the application requirements, such as the level of environmental protection needed, the degree of heat resistance required, and the level of mechanical support needed. Also, consider the material compatibility, the size and diameter of the hose shrink, and the shrink ratio.

Q4: What are the common types of hose shrinks?

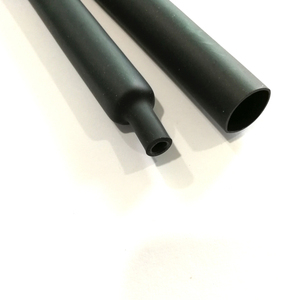

A4: The common types of hose shrinks include polyolefin heat shrink tubing, dual-wall heat shrink tubing, adhesive-lined tubing, and nylon heat shrink tubing. Other types include expandable polyester tubing and rigid PVC shrink tubing.

Q5: How are hose shrinks installed?

A5: Hose shrinks are installed by sliding them over the component to be shrunk and applying heat using a heat gun. The tubing will shrink tightly over the component when the appropriate amount of heat is applied. Some installations may require pre-activating the adhesive by using a hot air gun.