(72 products available)

A heatsink 800mm is a component with long fins, usually around 800mm in length. It is used to dissipate heat from electronic devices. Heatsinks come in different sizes, shapes, and materials, depending on the application. Here are the different types:

Passive Heatsink

These are the most common types of heatsinks. They are made of aluminum or copper. Passive heatsinks dissipate heat without using any power by relying on natural convection.

Active Heatsink

Active heatsinks are also made of aluminum or copper. They are fitted with a small fan on the heatsink. The fan uses power to create airflow and cool the heatsink more efficiently. Active heatsinks are commonly used in high-performance CPUs and GPUs.

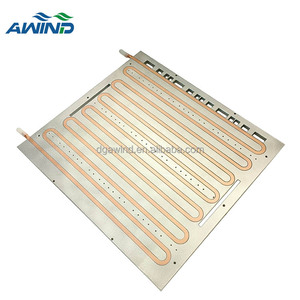

Heat Pipe Heatsink

These heatsinks use a copper tube called a heat pipe. The heat pipe is attached to the hot surface and transfers heat to the fins. Inside the heat pipe is a liquid that evaporates and condenses to move heat away from the source. Heat pipe heatsinks are effective for cooling without a fan.

Compound Heatsink

It consists of a base heatsink and several additional smaller heatsinks attached to the fins. This design increases cooling by using multiple heatsinks in one assembly. Compound heatsinks are typically used for high-power applications.

Graphene Heatsinks

Graphene heatsinks are a new design that uses graphene material. They are lightweight and have high thermal conductivity, allowing them to dissipate heat efficiently. Graphene heatsinks work well in small electronic devices that need cooling.

Liquid Cooling Heatsink

These heatsinks use liquid coolant to transfer heat away from the electronic component. The liquid circulates through a sealed system, dissipating heat more efficiently than air. Liquid cooling heatsinks are used in high-performance computers and overclocked CPUs.

Stacked Heatsink

Stacked heatsinks have multiple layers of fins that are stacked on top of each other. This design increases surface area and cooling performance without increasing the footprint. Staked heatsinks are used in applications where space is limited.

In the case of an 800mm heat sink, the features listed below are crucial to its effectiveness:

Material

Heatsinks are usually made of aluminum or copper. Aluminum is lighter and can be made into larger heatsinks, while copper is very good at conducting heat. Some heatsinks use a combination of aluminum and copper. The material helps spread the heat evenly over the whole heatsink so it cools better.

Design

H800mm heatsinks come in many shapes and sizes. The most common are fin-based, flat plate, and cylindrical. Fin-based heatsinks have long thin pieces that look like a radiator. Flat plate heatsinks are just flat surfaces. Cylindrical heatsinks are round tubes. The design depends on how much heat needs to be cooled and the space available.

Efficiency

Efficiency is very important for larger heatsinks. They need to cool big parts without letting them get too hot. Efficiency means cooling is done without using much power. For 800mm heatsinks, efficiency is measured by how well they transfer heat compared to their size. A more efficient heatsink will keep the part cooler while taking up less space and using less energy.

Size

There are smaller heatsinks for less powerful parts and much larger ones for things that produce a lot of heat. Size matters because a bigger heatsink can cool more powerful parts that get hotter. But it also means more space is required. The size has to fit the amount of heat that needs to be cooled and the available space.

Airflow

Airflow helps carry heat away from the heatsink. More air flowing means more cooling is done. Some heatsinks have fans attached to make air movement better. The fans help transfer heat away faster, especially for parts that get very hot. Airflow is especially crucial for cooling electronics like computer parts that work hard and produce a lot of heat.

Durability

The durability of heatsinks refers to how well they can work over many years without breaking. 800mm heatsinks are made to last a long time even if they are used a lot. They are built to withstand repeated heating and cooling without getting damaged. Durable heatsinks will continue to cool electronic parts effectively for their entire lifespan.

800mm heatsinks are widely used in various industries and applications, especially in high-power electronics and large-scale computing. Here are some common scenarios:

Power Electronics

800mm heatsinks are commonly used in power electronic devices such as thyristors, transistors, and IGBT (Insulated Gate Bipolar Transistor) modules. These devices are widely used in applications such as motor drives, renewable energy systems (e.g., solar inverters and wind turbine converters), and high-voltage direct current (HVDC) transmission. The large surface area of the 800mm heatsink dissipates heat generated by these power electronics during operation, ensuring they remain within safe temperature limits and preventing thermal failure.

Telecommunication Equipment

Telecommunication equipment, including base stations, radiofrequency (RF) amplifiers, and signal processors, often require substantial cooling to maintain reliable operation. 800mm heatsinks can be integrated into these systems to cool high-power components such as power amplifiers and modems. By dissipating heat efficiently, these heatsinks help ensure uninterrupted communication and reliable performance of telecommunication networks.

Data Centers and Server Farms

In data centers and server farms, maintaining optimal temperature conditions for IT equipment is critical to prevent overheating and ensure continuous operation. 800mm heatsinks can be employed in cooling systems to dissipate heat from high-density server racks, storage units, and networking gear. These heatsinks work in conjunction with fans, liquid cooling systems, or heat pipes to provide efficient thermal management in large-scale computing environments.

Industrial Equipment

Many industrial machines and devices rely on large heatsinks to cool their electronic components. For instance, welding machines, industrial robots, and automation controllers may utilize 800mm heatsinks to dissipate heat from power electronics or high-performance processors. The robust construction and large size of these heatsinks make them suitable for heavy-duty applications in harsh environments.

High-Power LED Arrays

LED lighting solutions, particularly high-power LED arrays used in stadium lighting, architectural illumination, and automotive lighting, may require substantial cooling to maintain optimal performance and longevity. An 800mm heatsink can be integrated into the design of these lighting systems to dissipate heat generated by the LEDs during operation.

When choosing an 800mm heatsink, there are several factors that can be considered. These factors will help buyers select the right product for their applications. They include:

Physical Configuration

Buyers should consider the physical configuration of the 800mm heat sink. This includes the mounting options, dimensions, and clearance around the socket. It is important for the heatsink to fit properly on the component it is cooling.

Material

The heatsink is available in different materials. This includes aluminum and copper. Aluminum is lightweight and cost-effective. On the other hand, copper offers excellent thermal conductivity. Business owners should choose a material that meets their thermal requirements.

Fan Configuration

The fan configuration plays an important role in the cooling performance of a heatsink. High-speed fans provide efficient cooling. However, they produce more noise than low-speed fans. Business owners should choose a fan configuration that meets the cooling needs of their system. At the same time, it should provide the required noise level.

Thermal Performance

The thermal performance of an 800mm heatsink is an important factor to consider. It determines the efficiency of the component cooling. Business owners should look at the thermal resistance, airflow, and dissipation capability. They should also consider the maximum temperature ratings. This helps to ensure optimal performance and reliability of their system.

Compatibility

Heatsinks come in different sizes and designs. Each is compatible with different components. Business owners should ensure that the heatsink is compatible with the motherboard, CPU, or GPU. They should also consider the socket type and power rating.

Noise Level

Many heatsinks operate differently depending on their designs and configurations. Some produce a high level of noise, while others are quieter. Business owners who prefer quieter operations should choose heatsinks that have low noise levels.

Ease of Installation

Business owners should also consider the installation process of the heatsink. For some configurations, professional installation is required. On the other hand, some heatsinks allow for simple DIY installation.

Q1: What are the common materials for heatsink 800mm?

A1: The most common materials for an 800mm heatsink are aluminum and copper. They are good at conducting and dissipating heat, making them ideal for use in semiconductor devices.

Q2: What factors should be considered when choosing an 800mm heatsink?

A2: When choosing an 800mm heatsink, it is important to consider the cooling requirements, compatibility, airflow, fan noise, and dimensions. All these factors will ensure that the selected heatsink is suitable for the intended application.

Q3: What is the role of fans in heatsink performance?

A3: Fans play an important role in heatsink performance by increasing the airflow and enhancing heat dissipation. By circulating air over the heatsink, the fans lower the temperature of the semiconductor device, ensuring optimal performance.

Q4: Can LED lights be installed on an 800mm heatsink?

A4: Yes, LED lights can be installed on an 800mm heatsink for aesthetic purposes and to provide illumination. The LED lights will be cooled properly by the heatsink, extending their lifespan and improving their performance.

Q5: What are the trends in the design and manufacture of 800mm heatsinks?

A5: The trends in the design and manufacture of 800mm heatsink include the incorporation of sustainable materials, advanced manufacturing techniques, and the use of smart technologies. These developments have led to the creation of more efficient, durable, and environmentally friendly heatsinks.