(12995 products available)

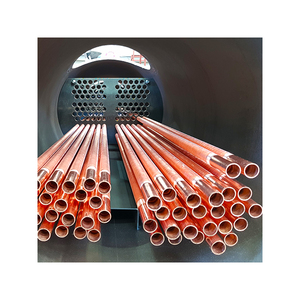

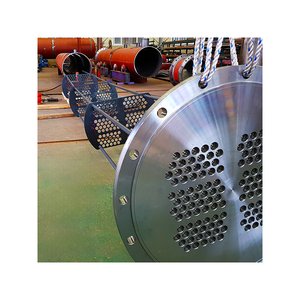

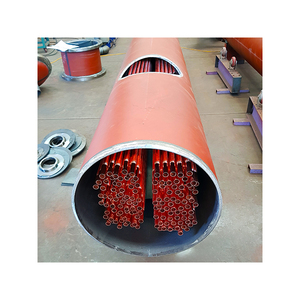

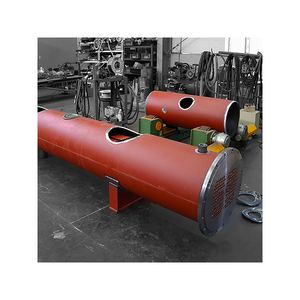

A heat exchanger is a thermal management device used to transfer heat between two or more fluid streams, which can be liquids, gases, or a combination of both. Heat exchangers are mainly applied in the following industries: chemical processing, oil and gas, HVAC, power generation, food and beverage, pulp and paper, pharmaceuticals, metals and mining, water treatment, and reflus condensers.

According to the flow patterns of the working media, heat exchangers are typically divided into three types: counterflow heat exchangers, co-current or parallel flow heat exchangers, and crossflow heat exchangers.

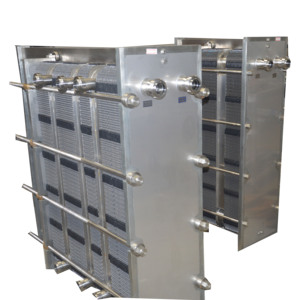

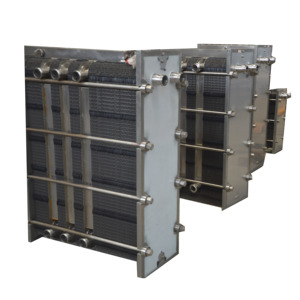

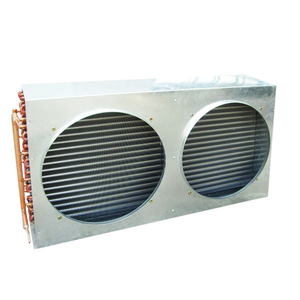

According to the structure and working principle, heat exchangers are also classified into several types.

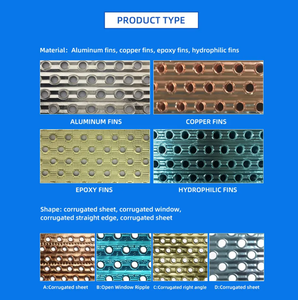

Materials

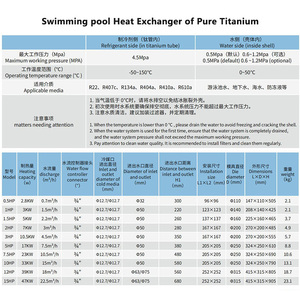

Heat exchanger components are made primarily of steel, including carbon, stainless, and alloys. However, depending on the PHE model, they may also include aluminum or titanium. When PHE are fat exchangers for oil, they typically involve aluminum because, during oil heat transfer, aluminum can withstand the conditions. On the other hand, titanium is used in marine or seawater applications because it has high resistance to corrosion and limescale buildup.

Design

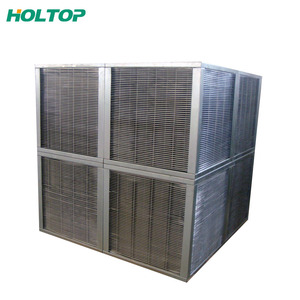

Heat exchangers have various designs to meet specific industrial needs and are typically available in both counterflow and parallel flow.

Counterflow means that the incoming cold fluid and the outgoing hot fluid flow in opposite directions, while parallel flow means that both fluids flow in the same direction. Counterflow heat exchangers are more efficiently than parallel ones because, in the counterflow, cold fluid gradually receives heat as both fluids move along.

Connection Types

Heat exchangers often have threaded or socket weld connections. Socket welds are used when the alloy material needs to be protected from being exposed to air. This may be due to the fluid that the exchanger is transferring. Socket weld involves the insertion of a pipe into a socket groove that's been machined on a fitting. Meanwhile, socket welds are suitable for large valves. Threaded connections are commonly used for small parts, but they also have a downside since the threads could become damaged over time.

Inspection

A visual examination of the heat exchanger for signs of leaks, corrosion, or damage. Looking closely at the gaskets and seals to determine if they're worn out or not, the components are crucial because, as discussed, fluids are exchanged. If there's a fluid leak into another space, it could present a hazard. Therefore, examining the gaskets and seals should be the first inspection task.)

Clean

Removing any deposits or contaminants is part of the heat exchanger's regular cleaning. This way, it prevents clogs and maintains a stable energy transfer rate. The cleaning method will vary according to the exchanger type and the kind of deposits that need to be removed. For example, chemical cleaning is usually efficient when working with limescale or mineral deposits.

Replace

Once the user or technician inspects the heat exchanger's gaskets and seals, it's now possible to notice if any components need to be replaced or are worn out. The replacement parts should be OEM, flaw-free, and fit precisely to make sure that they fulfill the user's heat exchange demands.

Industrial manufacturing processes

Heat exchangers are widely used in various manufacturing industries such as the petrochemical industry, iron and steel industry, chemical industry, mining industry, and pharmaceutical industry. They play a crucial role in industrial manufacturing by providing temperature regulation and controlling heat.

Energy recovery

Heat exchangers are widely utilized in the process of energy recovery. They transfer heat from waste gas, waste liquid, and waste heat generated during industrial production processes to other production processes or different industries. This not only conserves energy but also reduces energy consumption.

Power generation

Heat exchangers hold significant importance in the field of power generation. They are widely used in power plants, such as thermal power plants, nuclear power plants, and hydropower plants, playing a key role in transferring heat. This facilitates power generation through various methods. For example, in thermal power plants, heat exchangers transfer heat to boilers to produce steam. The steam, in turn, drives turbines to generate electricity.

Aviation and aerospace

In the fields of aviation and aerospace, heat exchangers play a crucial role. They are extensively utilized in aircraft and spacecraft. Heat exchangers are primarily responsible for regulating temperature and dissipating heat. This ensures the normal functioning of equipment and components, providing favorable protection for flight and safety.

Marine applications

Heat exchangers find important applications in the marine domain. They are widely used in ships and submarines. Heat exchangers serve to regulate the temperature of equipment and components aboard the vessels. Simultaneously, they facilitate the dissipation of heat generated by the machinery. This ensures the normal operation and reliability of marine vehicles in challenging maritime environments.

Before placing an order for industrial heat exchangers, five crucial factors need to be examined closely. They include the stable, economic, and safe operating conditions of the heat exchanger. The chemical, mechanical, and thermal properties of the heat exchanger, including its corrosion resistance and reliability.

The buyer must check the heat exchanger's working medium to see whether it is a gas, liquid, steam, or mixture of any of them. This will determine whether a shell-and-tube heat exchanger is adequate for the industrial use in question or whether other types will have to be considered. The choice of heat exchanger also depends on how corrosive the working medium in the industry is. If it is liquid, the corrosion may occur at very high levels. In such a case, the DBuyer'sdifier must ensure that the heat exchanger has a corrosion-resistant material or protective coating. The working pressure of the industry determines whether the heat exchanger will have to withstand high pressure or be at atmospheric pressure. When the working pressure is high, the parts of the heat exchanger need to be more robust and tightly sealed to eliminate any leakage.

Industrial buyers also have to check the working temperature of the heat exchangers. If the temperature fluctuates between very high and very low, the heat exchanger's components must be stable enough not to wear out. Otherwise, the heat exchanger will not work properly, and wastages will take place in the industry. Other common factors to look for are the design parameters. These include capacity, dimensions, connection methods, flow patterns, and the standards and regulations compliances of the heat exchanger.

Finally, industrial buyers must determine whether they will buy a single heat exchanger unit or a whole system of heat exchangers together.

Q: What is the difference between a heat exchanger and a condenser?

A: The primary difference between a heat exchanger and a condenser is that a heat exchanger transfers heat from one fluid to another. On the other hand, a condenser changes the vapor of a fluid into a liquid by releasing its heat into another fluid.

Q: What type of heat exchanger is most efficient?

A: Plate heat exchangers are typically more efficient than shell and tube heat exchangers. This is because they have larger surface areas for heat transfer within a compact volume. However, the efficiency of a heat exchanger also depends on its design, operating conditions, and the fluids being used.

Q: What are some signs of heat exchanger failure?

A: Some signs indicating that the heat exchanger may be failing include a rise in operating temperature, unusual pressure drops, changes in fluid composition, noise and vibration, and any signs of leaks. If any of these indicators are present, the heat exchanger should be inspected to rule out any failures.

Q: What is the lifespan of a heat exchanger?

A: Heat exchangers can last between 10 to 30 years, depending on various factors, such as the material used, the design, and the operating conditions. Heat exchangers constantly transfer heat between two or more fluids. As a result, they are subjected to thermal cycling, which can cause expansion and contraction. Additionally, the fluid passing through the heat exchanger can be corrosive, which can contribute to the degradation of the unit.