Types of Half Coupling 3

Half coupling 3 types, which are distinct, feature female threaded ends that permit the joining of pipes, as well as additional fittings like valves, nozzles, etc. They have been considered a "half" version of a solid coupling since they are used to connect two sections of a pipe but are attached to something fixed on one end rather than rotating through the complete circumference of the coupling.

Stainless steel half coupling 3 is often used to connect a pipe to a vessel or another piece of equipment. Though not typically associated with supporting a load, the half coupling is still widely used. Below are the three types of half coupling 3:

- Socket weld half coupling: This type is welded to the surface of the pipe, and thus, it is used in places where it will be exposed to constantly high pressure.

- Threaded half coupling: This is joined with the two pipe ends united either by internal threads or an externally threaded portion of the pipe. Threaded couplings can be used to unite dissimilar materials that may be uncomfortably welded, such as copper and galvanized steel.

- Welded half coupling: A welded coupling, like a socket weld coupling, is used for high-pressure applications but provides the benefit of being a full coupling. A welded half coupling is also very useful when the pressure is not very high but for connecting a pipe to any other equipment like a valve or a nozzle.

Industrial Applications of Half Coupling 3

The half coupling is a strong and important pipe fitting in various industries to ensure required fluid or gas transport integrity. Below are some common industrial applications of the half coupling:

- Oil and gas: In the oil and gas extraction and refining industry, half couplings are used to join pipelines that transport crude oil, natural gas, and other related products. Due to its strength and resistance to corrosion, stainless steel is often used to construct couplings to operate in extreme environments.

- Power generation: In power plants, steam, water, and other fluids are transported through piping systems to generate electricity. Half couplings are used to connect pipes in these systems.

- Water treatment: In water and wastewater treatment systems, half cement couplings are used to connect piping systems that transport water for treatment and distribution and wastewater for disposal or reuse.

- Construction: In the construction industry, half couplings are used to install plumbing and fire protection systems in commercial and residential buildings. They are used to join pipes for delivering potable water, sewage, and other fluids and installing fire sprinklers.",

"Transportation of two pipes connected with a half cement coupling usually takes place in most normal businesses. This includes manufacturing plants, commercial complexes, etc. The installing and carrying will typically be of non-dangerous fluids, water, and air. Depending on the material used in their making, half couplings can also be employed in areas requiring a more robust solution, such as high temperatures and corrosive substances.

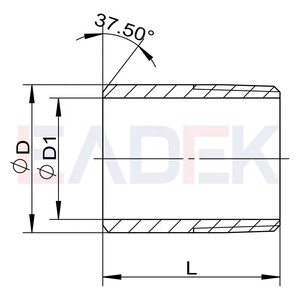

Product Specifications and Features of Half Coupling 3

Technical specifications/key features

The main difference is that a half coupling is used to attach a pipe to a device like a valve and make it possible to extend the pipe run rather than supporting the load. It features female threaded ends that permit the joining of pipes, valves, nozzles, etc. Though not typically associated with supporting a load, the half coupling is still widely used. Below are some of the specifications of the half coupling 3:

- Material: Stainless steel, carbon steel, aluminum, or alloy.

- Size: It is available in a range from 0.25 inches to 6 inches nominal pipe size.

- Standards compliance: ANSI/ASME B16.9, ANSI/ASME B16.11, MSS SP-95, MSS SP-79.

- Finish: Couplings have a smooth finish to allow tight welding with other fittings or pipes.

- Corrosion resistance: Stainless steel couplings will be very useful in places exposed to moist air, chemicals, or extreme heat, as they will not rust.

- Strong joint formation: Like socket weld and threaded half couplings, these are designed to provide a high-strength joint capable of bearing heavy loads and high-pressure tow or misaligned pipes.

- Versatile coupling application: Half couplings are used extensively in industries such as petrochemical power generation, marine, and construction, making them very versatile.

- Temperature tolerance: Half couplings can function under very low to extremely high temperatures, making them ideal for extreme conditions.

How to install/ use

- Joining pipes: Half couples are used where two pipes of equal diameter need to be joined. A full coupling would be used where the connecting pipes are of different diameters. As half couplings have threaded ends, they can be easily screwed onto the two ends of the pipe to effect the joint.

- Connecting: Half couplings are also used to connect the two parts of a divided pipe run. Such a connection is usually done with flexible couplings that allow some movement. Rigid half couplings are also used in the joints of two fixed pipes.

- Mounting: In other applications, half cement couplings are welded onto the pipe to serve as a point to attach a support or bracket. This way, the coupling supports the entire weight of the pipe once it is mounted.

Maintenance and repair

- Corrosion prevention: Stainless steel half couplings are resistant to corrosion and must be regularly inspected for rust, pitting, etc. Any early sign of degradation means replacing the damaged couplings instantly before causing a system failure. One of the best ways to maintain half cement couplings that are exposed to moist air, chemicals, or extreme heat is to cover them up with a protective coating.

- Frequent visual checks: The coupling area should be frequently checked in operation for unusual signs like leaks, misalignments, or vibrations. Early detection will solve small issues before they explode into big problems.

- Alignment maintenance: Ensure that where connecting two pipe runs or attaching to support brackets, the coupled pipes remain aligned, are vibrating, and are not bearing against each other. Pipe alignment tools can assist in achieving proper alignment.

- Replacement readiness: One major and critical maintenance task is to have half coupling 3 ready for replacement at any time. Couplings are subjected to wear and tear, stressing, and fatigue, which may make them at some point useless. Watch out for signs on the coupling or the pipe joint. Consider having a wrench and hacksaw or coupling remover handy if you need to do the replacement anytime soon.

Quality and Safety Considerations of Half Coupling 3

Below are some of the quality and safety considerations of half coupling 3 of a kinds:

- Material quality: Half couplings should be of premium quality materials as only low-quality materials coupled with negligence and poor working conditions are fatal for operations involving severe pressures, temperatures, or corrosive substances. Stainless steel, carbon steel, and alloy materials offer phenomenal strength and resist corrosion.

- Coupling strength: Ensure the coupling used in the system has the strength to sustain the pressure exerted by the contained fluid or gas. Regularly check for signs of wear, corrosion, and fatigue, and replace couplings when necessary to avoid hazards.

- Proper installation: Safety risks will not only increase; the system will also be rendered inefficient if the half cement couplings are improperly installed. Ensure the threads on half couplings and the pipe ends are the same. Use the correct tools and forms of coupling. Don't overtighten or, at the same time, don't leave them loosely fixed.

- Alignment: The pipes should be aligned during installation. Pipe misalignment can lead to cracks and undue stress on the coupling, endangering those working around the installation. Use pipe clamps or supports to ensure stability.

- Regular inspections: Regular post-setup inspections are mandatory to avoid future problems. These include bending, leakage, and alignment. Compound and Pressure test are some tests that check the integrity of a Coupling.

- Environmental considerations: Stainless steel, half coupling three is manufactured with the environment in mind and can be recycled and reused. When replacing worn-out couplings, the environment will be safer if the old ones are recycled.

Q & A

Q. Can a socket weld half coupling be used on a high-pressure system?

A: Yes, socket weld half couplings are great for high-pressure applications. Since the coupling is welded to the pipe ends, a sturdy joint that can withstand great pressure is achieved.

Q. What is the function of a threaded half coupling?

A: A threaded half coupling is used to connect two pipes with internal threads or an externally threaded portion of the pipe. It can also connect dissimilar materials that cannot be welded, like copper and galvanized steel.

Q. How does a welded half coupling differ from a socket weld coupling?

A: Like a socket weld coupling, a welded half coupling is used to join two pipe ends. However, a welded coupling is meant to connect one end of the coupling attached to a vessel or other equipment. This means that a welded half coupling is just a full coupling that is not used to support loads.

Q. What maintains the position of the welded half coupling?

A: A jig is used to hold the pipe in place as the weld is being carried out. Therefore, the coupling and pipe will not be misaligned during the welding process.

Q. What maintenance is required for the stainless steel half cement coupling?

A: The stainless steel half cement coupling should be protected from corrosive substances such as chemicals and ideally inspected in environments with high heat. Apart from that, the pipeline system should be inspected often for leaks, signs of wear and tear, and misalignment.