(8364 products available)

When it comes to car engines, the most important thing is to have the most power possible. The more power, the better the car will drive. A lot of cars today come with a supercharger already built into the engine. It is a device that can make the car run better. It can be added to a good turbocharger to help with the driving experience. But what exactly is a turbocharger? And what are the types of turbochargers?

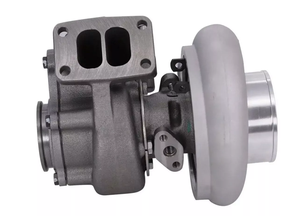

A good turbocharger is a turbine-driven forced induction device that is used to boost the power of the internal combustion engine. The good turbocharger uses the exhaust air from the engine to spin a fan, which then pulls more air into the engine, allowing it to breathe better. This means the engine can burn more fuel, which results in more power output. A turbocharger can increase an engine's power by 30% to 50%.

There are two main types of turbochargers:

Single Turbo

Single turbos are the most common type of turbocharger. As the name suggests, this type of turbocharger has a single turbine and compressor wheel. Single turbochargers are further divided into several sub-types based on their design:

Axial turbo: Axial turbines use blades to push air parallel to the shaft. They are mostly found in the turbochargers of jet engines.

Centrifugal turbo: Centrifugal turbines use blades to push air outward to the casing. They are the most common turbine type found in automotive turbochargers.

Radial turbo: Radial turbines feature blades that push air in both radial and axial directions. They are more efficient than axial turbines but are less efficient than centrifugal turbines.

Dual Turbo

Dual turbos use two turbine and compressor wheel sets. Like single turbochargers, dual turbochargers are divided into several sub-types:

Parallel twin-turbo: These turbos use two turbines and compressor wheels. Each turbine powers its own compressor, which allows for more even power delivery. This type of turbocharger is often found in high-performance sports cars.

V6 twin-turbo: V6 engines use a single turbo for each pair of cylinders. This means that a V6 engine will have six cylinders arranged in two banks of three. Each bank of three cylinders uses one turbocharger, resulting in a total of two turbochargers for the engine.

Manufacturers provide specifications to help users understand how to use and take care of a turbocharged engine. Here are some common specifications for good turbochargers:

Specifications

1. Size: The turbocharger size refers to the turbine and compressor dimensions. It affects the amount of exhaust gas required to spin the turbine and how much air the compressor can move. Larger turbos generate more power but have more lag. The size should match the engine for efficiency and performance. Turbochargers come in different sizes denoted by A/R numbers. A high A/R number means a larger turbine housing. The most common A/R ratio for a good turbo is between 0.60 and 0.70.

2. Pressure Ratio: Pressure ratio measures the difference between the air pressure entering and leaving the turbo. A high-pressure ratio means the turbo forces more air into the engine. Pressure ratios range from 2.0 to 4.0, depending on the turbo size and application.

3. Speed: Speed specifications indicate how fast the turbine and compressor spin. High speeds increase efficiency and power output. The turbine RPM can reach 200,000, while the compressor turns at 100,000 RPM. The speeds vary by turbocharger design and materials.

Maintaining a turbocharged engine is vital for optimal performance and longevity. Here are some tips:

Maintenance

1. Use High-Quality Oil: Good oil keeps the turbo lubricated and clean. The oil should meet the manufacturer's requirements. The oil change interval must be maintained to prevent buildup and protect the turbo.

2. Proper Cooldown: Allowing the engine to idle before turning off the ignition cools the turbo. This practice prevents oil coking, which can damage the turbo over time.

3. Clean Air Filter: Regularly checking and cleaning the air filter ensures proper airflow to the turbo. A clogged filter strains the turbo and reduces performance.

4. Inspect Exhaust Leaks: Checking for exhaust leaks is crucial as they can hinder turbo performance. Fixing any leaks ensures optimal turbocharger function.

Some of the factors to consider when choosing a good turbocharger for different applications are as follows.

Engine Size:

The displacement and type of the engine should be considered. Larger engines can utilize bigger turbochargers to generate more power, while smaller engines may need a compact turbo to avoid lag.

Compressor Wheel:

The size and material of this component affect airflow into the engine. A larger wheel improves top-end power but may reduce low-end torque. Buyers should choose based on the RPM range they desire to optimize.

Turbine Wheel:

This determines how exhaust gases spin the turbine. Wheels with more blades provide smoother power delivery, while those made from lightweight materials boost response times. The number of blades and material should be examined before purchase.

Compressor Housing:

Housing affects compressor efficiency and pressure ratios. Buyers can select a housing that best fits their desired goals, whether more boost is required or improved airflow with less resistance.

Turbine Housing:

This contains the turbine and shapes exhaust flow. It comes in various sizes that influence how quickly the turbo spools up (known as boost time). A smaller turbine housing provides quicker boosting at the expense of high-end performance, while larger housing generates greater overall thrust but lags initially before full force kicks in.

Bearing Type:

Bears are internal components that affect reliability and how smoothly the turbo spins. Buyers can opt for journal bearings for affordability and adequate function or step up to stronger ball or roller types best suited for extreme pressures and speeds.

Wastegate:

This regulates boost levels. Buyers can choose internal wastegates, which suffice for most applications, or go with external ones if precise control over the amount of compression desired is necessary.

Intercooler:

It cools the air before it enters the engine. A larger intercooler will provide denser oxygen to fuel, maximizing thrust but requiring more space in the vehicle.

Oil Supply Method:

The turbocharger needs lubrication. Buyers should consider how it will be oiled; options include direct lines from the engine's oil system or using high-temperature grease in some lower-maintenance cases.

Here's a step-by-step guide on how to replace a turbocharger:

Preparation:

Gather the necessary tools, including sockets, wrenches, pliers, and torque wrench. Obtain a new turbocharger and any required gaskets or seals. Disconnect the battery.

Drain the oil:

Drain the engine oil to prevent leaks and excessive oil drainage when removing the turbo.

Remove the intake and exhaust:

Take out the intake pipe and intercooler connections, then remove the intercooler and set it aside. Remove the exhaust downpipe from the turbo.

Disconnect the oil lines:

Loosen and disconnect the oil feed and return lines from the turbocharger using a wrench. Be prepared for some oil spillage.

Disconnect the actuator:

Unplug the vacuum line or electrical connector (for variable geometry turbos) from the turbo actuator.

Remove the turbo:

Loosen the bolts holding the turbo to the exhaust manifold and carefully lift the turbo out of its mounting.

Install the new turbo:

Position the new turbocharger onto the manifold and secure it with bolts, tightening them to the manufacturer's specs. Reconnect the actuator.

Reconnect oil lines:

Clean any old oil residue from the lines and tighten the new turbocharger's oil feed and return lines with a wrench to prevent leaks.

Reinstall intake and exhaust components:

Reconnect the intake pipe and intercooler, then install the intercooler. Reattach the exhaust downpipe to the turbo.

Fill the oil:

Pour fresh engine oil into the system, ensuring the correct level.

Q1: How long does a Turbo last?

A1: Turbos can last between 100,000 and 200,000 miles. However, they can also be damaged within a few thousand miles. The lifespan of a turbo depends on various factors. Proper maintenance increases the likelihood of a turbo lasting long.

Q2: What causes turbos to fail?

A2: The most common cause of turbo failure is a lack of lubrication. This is usually due to oil contamination or a damaged pump. Other factors are wear and tear, foreign objects entering the turbo, and high exhaust back pressure.

Q3: Should people worry about turbo lag?

A3: Turbo lag is not a worry for most people. It only affects drivers of high-performance vehicles. Lag occurs between the throttle input and the delivery of power by the engine.

Q4: Do turbos make noise?

A4: Yes, they can make several noises. Some are normal, while others indicate a problem. A good turbo makes a whining noise when accelerating. It should be silent during deceleration. If it makes a rattling sound, the bearings could be worn out. An hiss could be from an air leak.