(456 products available)

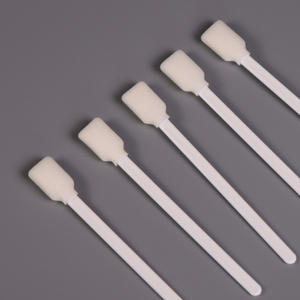

Foam optical swabs have a variety of applications, from cleaning delicate optical components to medical uses. Different types of foam optical swabs are listed below:

Regular Foam Tip

Regular foam tips are generic swabs made of soft, porous foam that cleans and absorbs liquids. They have a small, cylindrical foam head attached to a sturdy stick. The foam is tightly packed so it won't fall apart easily. These swabs are versatile and can be used for various purposes, such as cleaning small crevices or applying ointments. Their low cost and disposable nature make them attractive to many consumers.

Large Foam Tip

Large foam tips are similar to regular foam swabs but have a bigger foam head. This makes them suitable for cleaning larger areas or applying products more quickly. The larger foam head covers more surface area, making it ideal for cleaning larger objects or applying ointments over a wider area. However, they may not be suitable for tight spaces where the regular-sized foam swab can fit. The large foam tip is also disposable and cost-effective.

Small Foam Tip

Small foam tips are like regular swabs but have a smaller foam head. This makes them ideal for cleaning small crevices or applying products precisely. The small size allows it to reach tight spots that larger swabs cannot. These are especially useful for cleaning the inside of electronic devices, model cars, and other toys. They may be used in makeup applications to apply and blend products in small areas like the corners of the eyes or around the nose.

Pointed Foam Tip

Pointed foam tips are similar to regular swabs but have a pointed foam head. This makes them ideal for cleaning tight spaces or applying products precisely. The pointed tip allows it to reach corners and other hard-to-reach areas that regular foam swabs cannot. This makes them especially useful for cleaning the inside of electronic devices, model cars, and other toys. They may be used in makeup applications to apply and blend products in small areas like the corners of the eyes or around the nose.

Paddle Foam Tip

Paddle foam tips have a flat, paddle-shaped foam head attached to a stick. They are primarily used for applying and smoothing out products like creams, gels, and ointments. The flat paddle shape allows for spreading the product evenly over a surface. This makes it ideal for medical applications such as applying antiseptic ointments to larger wounds. It can also be used for cleaning flat surfaces or removing dust and debris.

Specialized Foam Tip

Specialized foam tips are designed for specific applications, such as cleaning delicate optical components, hearing aids, and other specialized medical equipment. These foam tips are made of high-quality materials and are more durable than regular foam swabs. They may be more expensive, but they offer better cleaning and application results.

When buying foam optical swabs in bulk, consider the type and quantity of the product to order. Businesses like hospitals and clinics will need a large quantity of the swab foam and in different sizes. For instance, a clinical lab may require large-headed swabs for sampling and smaller ones for other tests. Stock pharmacies may also require different sizes of foam swabs to cater to the needs of the general public.

Manufacturers may require specialized swabs to clean small machinery parts. In this case, they will opt for firm, small-headed swabs with a long handle. Businesses or manufacturers looking for foam swabs for cleaning electronic parts may choose those with a narrow head and short, non-conductive handle.

Another important factor to consider is the material of the swab head. Some swabs have a porous foam head, while others are non-porous. Non-porous swabs are more durable and, in some cases, reusable. They are an excellent choice for cleaning electronic parts. Consider the handle length and material, too. Swabs with a long handle can reach deep places and are mostly single-use. Short-handled swabs are ideal for applying makeup or other cosmetic uses.

Bulk buyers should also consider the packaging. Swabs in resealable bags are excellent for stocking shelves. Those packed in boxes may be suitable for distribution to hospitals and clinics. Custom packaging options are available for businesses looking to brand the product.

Optical foam swabs are vital in ensuring clean and precise optical equipment. Their soft tips and gentle cleaning properties make them perfect for various applications. Below is a simple guide on how to use them:

Gather Cleaning Materials

One must have several items on hand to clean the optical device. These include foam optical swabs, lens cleaning solution, microfiber cloth, and compressed air.

Prepare the Device for Cleaning

Before cleaning the optical device, ensure it is turned off and disconnected from any power source. This step will prevent any damage to the device or injury to the user. Use compressed air to blow off dust and debris from the device. Hold the device at an angle and spray short bursts of air. This step will help remove any loose particles that can scratch the lens when cleaning.

Clean the Lens with Foam Swabs

Dip the foam swab in the lens cleaning solution and then wring it out. Too much liquid can damage the optical device. Gently wipe the lens in a circular motion, starting from the outer edge and working toward the center. Apply slight pressure to remove smudges and fingerprints. Be patient and avoid rushing, as rushing may leave marks on the lens. Use a microfiber cloth to clean the lens further and remove any remaining solution.

Clean Other Parts of the Device

Other parts of the optical device, such as the viewfinder, eyepiece, and body, can be cleaned using the foam optical swab. Follow the same cleaning process as the lens, but avoid using too much cleaning solution. For the viewfinder and eyepiece, gently wipe them in a straight line instead of a circular motion to avoid streaks.

Reassemble the Device

After cleaning all parts of the optical device, reassemble it. Check if all parts are functioning properly and put away the cleaning materials.

When using foam optical swabs for cleaning, it is essential to ensure the safety of the optical device and the user. Here are some precautions to take:

Use the Right Foam Swab

There are different types of foam optical swabs, each designed for a specific application. When cleaning an optical device, use the appropriate swab to avoid damaging the device. For example, larger swabs clean camera lenses, while smaller ones clean eyepieces and viewfinders.

Avoid Excessive Pressure

Applying too much pressure when cleaning the lens with a foam optical swab can scratch it. Use gentle pressure and circular motions to clean the lens. If stubborn dirt or smudges refuse to come off, persist; they may be better off using more specialized cleaning tools.

Use the Right Amount of Cleaning Solution

Using too much cleaning solution can damage the optical device. Wring out excess liquid from the foam swab before cleaning the lens. The lens should only be slightly moist.

Work in a Dust-Free Environment

Optical devices are prone to dust and debris, which can scratch the lens. When cleaning the device, work in a dust-free environment to prevent more particles from entering it. Close all windows and turn off fans to create a safe cleaning zone.

Optical foam swabs have several important functions and features that cater to different requirements. Below are some of them:

These optical applicator tips are primarily designed for cleaning and application purposes. Their foam material gently cleans surfaces without scratching or causing damage, making them ideal for cleaning delicate optical components like lenses, filters, and sensors in cameras, microscopes, and other imaging devices. The porous structure of the foam allows it to absorb and retain cleaning solutions or fluids when applying them to surfaces, ensuring even distribution and effective cleaning. The soft and uniform texture of the foam also makes these swabs suitable for applying makeup or other cosmetic products, as they provide a smooth and flawless finish.

Q1: What is the difference between foam and lint-free swabs?

A1: Although both kinds of optical swabs can be used for cleaning purposes, foam optical swabs are specifically designed for delicate surfaces like camera sensors and other electronic components. Their soft, porous texture allows them to absorb and hold cleaning solutions without leaving behind lint or residue. Lint-free swabs may not have the same level of absorbency or ability to retain cleaning fluids as foam swabs do.

Q2: What is the difference between a cotton swab and a foam swab?

A2: Foam swabs are superior to cotton ones because they do not leave behind any debris or lint, as cotton does. The foam tips on foam swabs are much softer and smoother than cotton fibers, which may scratch or damage delicate surfaces. This makes foam swabs ideal for cleaning and sampling purposes where no residue must be left behind or where the surface will be damaged.

Q3: Are foam swabs sterile?

A3: Many kinds of foam optical swabs are manufactured in a clean and controlled environment, packaged, and sealed so that they remain sterile. These are ideal for use in medical or clinical settings. It is essential to read the packaging carefully to know whether the swabs are sterile or not. If they are not, they must be sterilized before use.

Q4: Can foam swabs be washed and reused?

A4: Foam optical swabs are generally not meant to be washed and reused. However, they can be cleaned if intended for reuse. Cleaning them will require mild soap and water. Once cleaned, they should be dried thoroughly before being used again. In most cases, foam optical swabs are designed for single use only and should be disposed of after use to maintain hygiene and safety standards.