(2801 products available)

Ready to Ship

Ready to Ship

Foam cleaning swabs are an integral part of the cleaning process in different industries. There are different types of foam cleaning swabs designed for various applications and environments. Below are the main types of foam cleaning swabs:

General Purpose Foam Swabs

These are versatile swabs made with high-quality foam tips. The tips may be either firm or flexible, and they are securely attached to long plastic or wooden handles. General-purpose foam swabs are widely used in various applications, including cleaning delicate surfaces, electronics, and laboratory equipment. Their adaptability makes them suitable for everyday cleaning tasks where regular cotton swabs fall short.

Antistatic Foam Swabs

Antistatic foam swabs are specifically designed to clean electronic components without generating static electricity that could damage sensitive parts. These swabs are made from antistatic materials, and the foam is bonded to a sturdy, non-static handle. The foam is usually soft and non-abrasive, making it ideal for cleaning circuit boards, connectors, and other electronic devices. Industries like electronics manufacturing, telecommunications, and computer hardware use antistatic foam swabs to ensure the safety and reliability of electronic devices.

Micro Foam Swabs

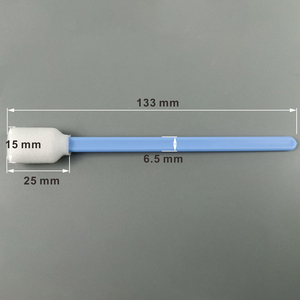

These are small, specialized swabs with tiny, porous foam tips. The tips may be cylindrical or paddle-shaped, and they are mounted on thin, rigid plastic or metal shafts. Micro foam cleaning swabs are designed for precision cleaning in hard-to-reach areas, crevices, and tight spaces. They are commonly used in the medical field, such as cleaning and sampling in surgical procedures, laboratory experiments, and pharmaceutical manufacturing. Other areas that use micro-foam swabs include telecommunications and optics, where fiber optic connectors require meticulous cleaning.

Specialized Foam Swabs

These include swabs tailored for specific industries or applications. Examples include large foam cleaning swabs used in the medical field for specimen collection and surgical procedures, as well as swabs designed for cleaning optical surfaces like camera lenses, microscopes, and telescopes. Other specialized foam swabs include those with fire-retardant properties for cleaning in environments where fire hazards are a concern.

Business buyers should analyze the following factors before choosing medical foam cleaning swabs for bulk purchase.

Application

Buyers should be aware of the intended purpose of the foam cleaning swab. Some may be used for general cleaning, while others are designed for specific applications, such as cleaning delicate electronic components, medical devices, or precision instruments. Identifying the application requirements will ensure that buyers choose the right type of swab for their needs.

Foam head density and size

The density and size of the foam head affect the cleaning efficiency and absorbency of the swab. Higher-density foam heads are more durable and can withstand rough cleaning, while lower-density heads are softer and more suitable for gentle cleaning. The size of the foam head should also be considered, as larger heads cover more surface area but may not fit into tight spaces.

Handle length and material

The handle length and material vary among different types of foam cleaning swabs. Buyers can find short handles, which are suitable for small-scale cleaning tasks or cleaning in confined spaces. Long handles are ideal for hard-to-reach areas or larger cleaning jobs. The material used to make the handle also differs, with some being more rigid and others being flexible.

Foam attachment and quality

The quality of the foam attachment is crucial when choosing cleaning swabs. Higher-quality foam attachments are tightly bonded to the handle and won't easily come off during use. Some are even reinforced with a plastic base for added durability. Buyers should also check the density and texture of the foam, as these factors can affect the swab's cleaning efficiency and effectiveness.

Packaging and quantity

Foam cleaning swabs are available in different packaging types and quantities. Some come in resealable packs, while others are packaged in bulk. The packaging type makes it easy for buyers to store the swabs and access them when needed. Swabs packaged in bulk have reduced overall costs, making them ideal for buyers who need large quantities for industrial use.

Foam swabs for cleaning have many uses, and it's essential to know how to use them to get the desired results. Below are some simple steps to follow when using foam cleaning swabs.

Preparing the area

It's essential to ensure the area around the device to be cleaned is well cleaned. This will make the cleaning process more efficient. Once the area is prepared, one must clean the device using the appropriate solvent or cleaning solution. Apply the solution to the foam cleaning stick and start cleaning the stubborn areas.

Choosing the right swab

Choose a swab with a foam head that's the right size to clean the targeted area. Larger swabs can clean bigger areas, while smaller ones are more precise. Consider the density of the foam as well; denser foam heads are better for absorbing liquids, while less dense foam heads are suitable for applying creams or ointments.

Gentle pressure

When using the swab, apply gentle pressure to avoid damaging delicate components. Allow the foam head to do most of the work. If stubborn dirt or residue remains, apply a little extra pressure, but be cautious.

Cleaning electronic parts

When using foam swabs to clean electronic devices, avoid using excessive liquid as it may damage the components. Focus on the foam head's cleaning tips and work gently. Ensure the device is powered off before cleaning, and avoid opening any sealed parts.

After cleaning

After cleaning, dispose of the foam swab properly. Do not flush used swabs down the toilet, as they may clog pipes; instead, throw them in the trash. Always wash hands after cleaning with foam swabs, especially in medical or personal care settings.

When using foam cleaning swabs, safety is critical to ensuring the product is used effectively. Below are some essential tips to ensure the product is used safely:

Avoid using excessive force

Applying excessive force can damage delicate components when cleaning with foam swabs. Use gentle pressure and let the foam head do most of the work.

Use the right kind of swab

Ensure the correct type of foam cleaning swab is used for the specific cleaning task. Some swabs are designed for cleaning electronic components, while others are suitable for medical or personal care applications.

Proper disposal

Many foam cleaning swabs are single-use and disposable. Properly dispose of the used swab to avoid contamination or environmental damage. Do not flush used swabs down the toilet, as they may clog pipes; instead, throw them in the trash. Used swabs may be contaminated with bodily fluids or chemicals; hence, proper disposal is essential.

Avoid flammable solvents

Avoid using flammable solvents when cleaning with foam swabs near open flames or sparks, as the foam material may be combustive.

Proper storage

Store foam cleaning swabs in a cool, dry place away from direct sunlight. Avoid storing near chemicals or substances that may contaminate the swabs. Proper storage ensures the cleaning sticks remain safe and effective for future use.

Cleaning swabs with foam tips are popular for cleaning delicate items. Their design and features enable them to perform the following functions effectively:

These foam cleaning swabs are suitable for cleaning lenses, circuit boards, and other sensitive equipment. The foam tips gently remove dust, dirt, and other contaminants without scratching the surface. The following are the key functions of foam cleaning swabs:

Foam cleaning swabs come in different sizes and shapes to cater to various cleaning needs. Some have a round foam tip, while others have a rectangular tip. Certain swabs have a long handle, making them reach deep into cleaning areas. Here are their key features:

Other features include a sturdy plastic handle and a porous foam head. Some swabs have a cylindrical shape, while others are rectangular. The sturdy handle provides good grip and control during cleaning. The porous foam head absorbs excess liquid and removes dirt.

Q1. What is the difference between foam cleaning swabs and regular cotton swabs?

A1. Foam cleaning swabs are designed for more specialized and precise cleaning tasks compared to regular cotton swabs. Their dense and smooth foam tips leave no debris and are ideal for cleaning sensitive electronic components, optical equipment, or surfaces where lint or residue must not be left behind. Regular cotton swabs may be suitable for general use but do not provide the same level of cleanliness and precision required for specialized applications.

Q2. Are foam cleaning swabs reusable?

A2. Most foam cleaning swabs are designed for single use and are disposed of after use. However, some types of foam cleaning swabs may be washed with water and mild detergent and reused several times. Such reusable swabs are typically made of more durable foam and have sturdy handles. It is essential to check the product specifications to know which kind of swab is reusable.

Q3. What are the characteristics of quality foam cleaning swabs?

A3. Quality foam cleaning swabs are made of highly absorbent and non-abrasive foam material that effectively cleans surfaces without leaving residue. They have a sturdy and comfortable handle, which can be made of plastic, wooden, or cardboard, depending on the type. Quality swabs are also manufactured with superior adhesive properties, allowing them to absorb cleaning agents effectively.

Q4. Can foam cleaning swabs be used with chemicals?

A4. Yes, foam cleaning swabs can be used with various cleaning chemicals, solvents, and solutions. The foam material does not react with most chemicals, making it suitable for applications in laboratories, electronics, and industrial settings. However, it is essential to check the chemical compatibility of the foam material to ensure it will not degrade or lose effectiveness when exposed to specific chemicals.