(15317 products available)

A flexible hose 2 inches is a 2-inch-thick hose commonly used for plumbing and fluid transfer applications. Due to its 2-inch diameter, this flexible plumbing pipe offers high flow rates, making it ideal for applications requiring significant fluid transfer. It is also lightweight and flexible, allowing for easy installation in tight spaces and around corners. A 2-inch flexible hose is commonly made from materials such as rubber, plastic, or metal. It is used in various applications, including HVAC systems, water supply lines, drainage systems, and flexible exhaust pipes. This 2-inch flexible hose can be used to transport air, water, oil, and other fluids. It is also used as a conduit for wires and cables in some applications.

There are several types of 2-inch flexible hoses, including:

Metal Hose:

A metal hose is a type of hose that is made entirely from metal. It is usually made from stainless steel, but other metals like aluminum can also be used. This flexible ducting is popular for many applications because of its strength, durability, and ability to withstand high temperatures and pressures. A metal hose can be used for both natural gas and liquid propane applications. These include connecting propane tanks to gas lines and providing a flexible connection point for gas lines.

Metal Braided Hose:

A metal braided hose is a type of hose that consists of an inner core, a metal braid, and an outer cover. The inner core is usually made from rubber or other flexible materials. The metal braid is made from stainless steel wire, which is woven tightly into a pattern. The outer cover is made from rubber or other materials that can withstand heat and abrasion. It is lighter in weight compared to a non-braided metal hose. This makes it easier to handle and install in various applications. The metal braid also helps to increase its strength and durability.

Flexible Rubber Hose:

A flexible rubber hose is a type of plumbing hose made from rubber or similar flexible materials. It is designed to be bent, twisted, or stretched without breaking or kinking. This type of hose is popular because of its versatility and ease of use. It is commonly used in applications where a hose needs to navigate around obstacles or fit into tight spaces. It is also lightweight and easy to handle, making it a good choice for DIY projects and applications where weight is a concern.

Lightweight and portable

Portability and lightweight are important features for many applications. A 2-inch flexible garden hose is lightweight and easy to carry around. Also, it is easy to store when not in use.

Flexibility

This hose is highly flexible and maneuverable. It can be curved around obstacles and tight corners without damaging or kinking. Flexibility makes it easy to use in complex areas and gardens with barriers like rocks and plants.

Compatibility with various fittings

Compatibility with multiple fittings is an important feature of a 2-inch flexible hose. It makes the hose versatile and easy to use with different systems and tools. This hose can connect various devices, irrigation systems, and pumps, making it ideal for many applications.

Excellent flow rate

The flow rate of a hose is the amount of water that passes through in a given time. A 2-inch flexible hose's high flow rate makes it perfect for applications that need a lot of water, like construction site dewatering and large-scale irrigation. The excellent flow rate ensures efficient watering of large gardens and trees.

Durability

A strong and robust material makes a 2-inch flexible hose. It is resistant to wear, tears, and punctures. This means it can survive harsh working conditions and last for many years with proper care. Its durability feature makes it a good investment for users.

Temperature resistance

Temperature resistance is a crucial feature for applications where the hose is exposed to extreme heat or cold. This ensures the hose maintains its flexibility and performance in any weather conditions.

Reduced friction loss

The design of a 2-inch flexible hose minimizes friction loss, which happens when water slides against the hose's interior. Reduced friction loss means more water reaches the end, increasing efficiency, especially in long-distance transportation.

Flexible hoses are widely used in various applications and industries. Their flexibility, lightweight, and ability to absorb vibration and movement make them ideal in different scenarios. Here are some common usage scenarios:

Plumbing

Flexible plumbing hoses are used in water supply lines. Ideally, these include; faucet connections, toilet supply lines, and washing machine hoses. Their flexibility allows for easy installation in tight spaces and connection to stationary water pipes.

HVAC Systems

HVAC systems use 2-inch flexible ducting to transport air from the central unit to the vents. The ducts' flexibility allow for easy routing around obstacles such as beams, walls, and corners. Also, these flexible hoses are used in refrigerant lines to connect the compressor to the condenser and evaporator units.

Automotive

Automobiles use flexible hoses in various applications. For example, brake systems, fuel lines, power steering, and coolant circulation. Their flexibility allows for easy connection of moving engine components to the stationary parts. Additionally, their ability to absorb vibrations and movements makes them ideal for use in engine compartments.

Industrial Machinery

Flexible hoses are prevalent in hydraulic systems. For instance, the connection of hydraulic pumps to motors, cylinders, and actuators. Their flexibility allows for smooth movement and connection of components in machinery. For example, in construction equipment, cranes, excavators, and forklifts.

Food and Beverage Industry

These flexible hoses are used in food processing plants, breweries, and dairy operations. They transport liquids, such as milk, beer, water, and other consumables. Their smooth interior walls facilitate easy cleaning and minimize bacterial growth.

Agriculture

Farm machinery and irrigation systems use flexible hoses. For instance, to transport water, fuel, and hydraulic fluids. Their flexibility allows for easy navigation of obstacles in the fields while maintaining a continuous flow.

Aerospace and Aviation

Flexible hoses are used in aircraft to transport hydraulic fluids, fuel lines, air conditioning, and engine oil. Their lightweight nature and ability to handle high pressures and temperatures make them ideal for aviation applications.

Marine

Flexible hoses are widely used in boats and ships. For instance, in fuel lines, water lines, sewage discharge, bilge pumps, and sanitation systems. They allow for easy routing around obstacles and moving parts in confined spaces.

When choosing a flexible metal hose, consider the applications for which the hose is intended. For example, if it is to be used in a vacuum system, the diameter, length, and material of construction are important. Another important factor is the connection type.

Flexible metal hoses can have different types of connections, such as welded or crimped fittings. Welded connections are more durable than crimped connections, but they are also more expensive. It is important to consider the cost when choosing the type of connection.

The working environment must be considered when selecting a 2-inch flexible metal hose. If the hose is to be used in an environment with high temperatures or pressure, it is important to choose a hose that can withstand those conditions. Similarly, if the hose is to be used in a corrosive environment, it is important to choose one that is made of a material that can withstand corrosion.

Another important factor to consider is the axial movement and angular misalignment. If the system is likely to experience axial movement and angular misalignment, it is important to choose a flexible metal hose that can accommodate those movements. This will help prevent damage to the system.

When choosing a 2-inch flexible metal hose, it is also important to consider the fluid being transported. Different fluids have different temperatures, pressures, and corrosive properties. Therefore, it is important to choose a hose that is compatible with the fluid.

These factors must be considered when choosing a flexible hose:

Q: What are the applications of a 2-inch flexible rubber hose?

A: Rubber hoses are used in agriculture for irrigation systems, in construction for transferring water to concrete pumps and in industrial settings for fluid transfer of liquids such as fuel, water and chemicals.

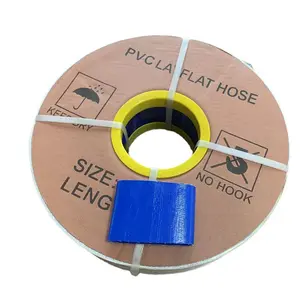

Q: What are the common materials for 2-inch flexible hoses?

A: The common materials include rubber, PVC and polyurethane. These materials are used because they are lightweight, resistant to kinks and flexible over a range of temperatures.

Q: How does a 2-inch flexible duct improve airflow?

A: Flexible ducts reduce the number of sharp turns and bends that air has to make, which is common in a rigid duct. This helps improve airflow and reduce air resistance.

Q: What are the factors to consider when buying a 2-inch flexible hose?

A: Consider the durability, the pressure rating, flexibility, compatibility with fluids and the temperature range. These factors are important to ensure the hose meets the required needs.

Q: Are 2-inch flexible hoses prone to leaks?

A: Hoses can leak if they are damaged, improperly installed or if they are exposed to harsh environmental conditions. Leaking can be prevented by regular inspections and proper installation.