(7501 products available)

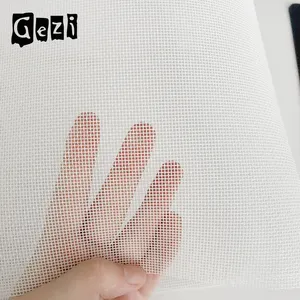

A mesh filter is a material-based device that allows certain liquids to pass and stops solids from passing through. The size of the mesh determines what can and cannot pass. A mesh sizing of 25 microns means that the holes in the mesh are 25 microns wide. The mesh can filter substances with diamoxes greater than 25 microns.

There are various materials and types for the mesh filters in a range of devices.

Specialty filters perform specific functions. Examples of these are:

Beverage companies use 25-micron filters to ensure that only the required ingredients go into the product. Brewing coffee requires a coffee filter mesh 25 microns to ensure only the coffee liquid passes through the filter. The filter mesh 25 microns specifications will be found in the product details of applicable filtering devices and may include details about the hole sizes, the materials used, and the maximum or minimum liquid pressures.

Specifications of filter mesh 25 microns:

Maintenance:

Filter mesh with a pore size of 25 microns is widely used in many industries, from mining to food processing. Here are some scenarios where mesh filters are commonly used.

Pharmaceutical Industry

In the pharmaceutical industry, liquid filters are essential components of drug manufacturing equipment. Pharmaceutical compounds must be free of contaminants to ensure patient safety. Hence, filters with a mesh size ranging from 1 to 25 microns are often used to make sure that only pure solutions enter processing equipment and final products.

Food and Beverage Processing

In the food and beverage industry, filter sieves are used to remove particles from raw materials like fruit juices and vegetable oils. For instance, 25-micron mesh filters are used to clarify fruit juice by removing pulp and sediment, thus extending the shelf life of the final product. Similarly, in the brewing industry, filters are installed in the lines carrying beer to bottling equipment to make sure unwanted hops and yeast particles do not end up in the final product.

Mining and Metallurgy

Metallurgy and mining industries use filters to remove impurities from valuable ores and achieve high levels of purity. Mesh filters are also used to strain water and other liquids during extraction processes like flotation and leaching.

Agriculture and Irrigation

Irrigation systems in agriculture often use mesh filters to remove sediments and impurities from the water used in irrigation. They help protect irrigation equipment and ensure uniform distribution of water to crops.

Chemical Production

In the chemical processing industry, mesh filters are used to remove solid particles from chemical reactions, ensuring high purity of the final products and preventing equipment clogging and damage.

Construction

In the construction industry, mesh filters are often used in plaster and mortar pumps to prevent the clogging of application equipment and ensure smooth material flow.

With many kinds of filter mesh available, businesses must consider many factors before buying them. First, they should think about the intended use and then select the material that is compatible with their application. The choice of micron size is also essential because it determines what particles or contaminants will be trapped by the filter.

Businesses should consider the durability of the filter mesh. Selecting a filter with adequate physical strength for the intended use is vital.

Customers won't buy the same filter size for every machine. They will need to buy a whole range of filters that are suitable for different machines. To make repeat purchases easy and to store stock, it's better if the filter mesh products have standard sizes. This makes it much easier to select and source products.

When searching for filter mesh products, buyers should also look for those compatible with the equipment and systems because they can offer seamless integration and performance. It is also worth looking for the filters that are easy to clean and reusable because they can provide maintenance cost savings over time.

While buying filters in bulk, buyers should also look for those that offer quantity discounts. Usually, a discount will be offered if a buyer purchases a specific number of filter screens in a single order. It also makes it more cost-effective to buy in bulk.

Finally, select filter screens that offer product warranty or guarantee, as this will provide customers with added protection and peace of mind.

Q1: Which is larger, 25 microns or 40 microns?

A1: 40 microns is larger than 25 microns. In fact, a 40-micron filter mesh is suitable for catching larger contaminants like sand, while a 25-micron filter mesh can capture finer particles, including larger grains of sand.

Q2: What does 25-micron mesh mean?

A2: 25-micron mesh refers to a filter media with holes or openings that measure 25 microns. A micron is one-millionth of a meter or one-thousandth of a millimeter. To visualize the size of a micron, human hair measures approximately 70 microns to 100 microns. The mesh size corresponds to how many inches are in one net per square inch. In this case, there are 625 holes per square inch.

Q3: Is 25 microns fine or course?

A3: 25 microns is classified as a fine filter. It can capture very fine particles and contaminants.

Q4: What is the porous size in microns for removing bacteria?

A4: The typical size of pores to filter out bacteria is around 0.2 microns. This is considerably smaller than 25 microns, underscoring the latter's capability to filter out fine particles unrelated to microbial content. Using a 25-micron mesh filter is ideal in settings where only non-biological contaminants, such as dust and sand, need to be filtered. In scenarios demanding the elimination of bacteria and other microorganisms, a filter with at least 0.2 micron-sized pores would be essential.