(13101 products available)

A film hose is a type of plastic or rubber tube used to transport liquids or gases in various film production applications. These hoses are lightweight, flexible, and durable, making them ideal for film and video production. Various types of film hoses are listed below:

Coiled Hoses:

The coiled film hoses are designed to coil up when not in use. This feature makes them easy to store and move around set locations. Additionally, they remain straight when filmmakers are using them, thus reducing kinks and knots.

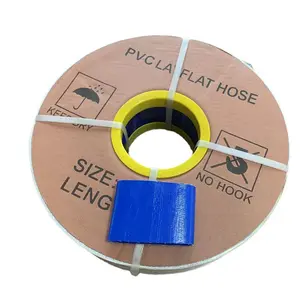

Flat Hoses:

These film hoses are designed to lay flat when not in use. They are easy to store, and filmmakers can use them in tight spaces. Additionally, they are suitable for applications where reduced wind resistance and drag are more important.

Reinforced Hoses:

These film hoses have a reinforcement layer that increases their strength and durability. They are designed to handle high pressures and are ideal for applications that require a long film hose that can withstand frequent movement and bending.

Helical Hoses:

These film hoses are characterized by a helical design that allows for increased flexibility and reduced friction. They are ideal for applications in dynamic environments where the film hose must frequently move and bend.

Specialty Film Hoses:

These are specific film hoses designed to be used in specialty applications. They include electrical film hoses, pressure film hoses, and marine film hoses.

Film hoses are essential in the film industry and have various features that make them suitable for their intended purpose. Here are some of their key features alongside their functions.

Lightweight and Flexible

Film hoses are lightweight, making them easy to handle and transport. This feature is essential during on-location shoots, where ease of movement is necessary. Their flexibility allows them to bend and curve easily, helping to position them in various angles and directions without causing strain or damage.

Durability

Film hoses are made of strong materials, ensuring they can withstand repeated use and resist wear, tear, and abrasion. This helps to reduce the cost of frequent replacements. They are also designed to be kink-resistant, which prevents any form of damage that may occur when the hose is bent at a sharp angle.

Compatibility

These hoses are compatible with various film equipment, including cameras, lighting, and power systems. This versatility makes them useful in many film production settings. Film hoses have various fittings and connectors that allow easy attachment and detachment from equipment, facilitating smooth operation during filming.

Heat Resistance

Some film hoses can withstand high temperatures, especially those used with lighting equipment. They prevent the hose from melting or catching fire. Others are designed to resist UV radiation, which helps to prevent degradation when exposed to sunlight.

Water Resistance

Film hoses are waterproof, preventing water from getting inside and damaging the internal components. This is important in outdoor shoots that may involve water or rain. They are also easy to clean and maintain, ensuring optimal performance.

Size and Length Variety

These hoses come in different sizes to suit different filming needs. They also come in different lengths, enabling filmmakers to choose the most appropriate length for their projects.

Film hoses (also known as film tubes) are used in various industries and applications where flexible, lightweight, and durable hoses are required. Here are some common usage scenarios:

Agriculture

Film hoses are widely used in agricultural irrigation systems. They distribute water efficiently and are often used in drip irrigation and sprinkler systems. They can also be used for fertigation, which is the application of fertilizers through irrigation systems.

Construction

These hoses are commonly used in construction sites. They are used for conveying water, cement, and other fluids. They are essential in concrete pumping and are used in dewatering systems.

Mining

In the mining industry, film hoses are used for the transportation of water, slurries, and other fluids. They are optimal in hydraulic systems and have a wide application in mineral processing.

Oil and Gas

These hoses are used extensively in the oil and gas industries. They are used for the transportation of crude oil, natural gas, and other hydrocarbons. Their flexibility allows them to be used in offshore drilling operations.

Manufacturing

Film hoses are commonly used in manufacturing industries. They are used for the transportation of water, chemicals, and other fluids. Their lightweight and flexible nature makes them ideal for use in various manufacturing processes.

Chemicals

These hoses are used for the transportation of chemicals, acids, and corrosive substances. They are made of materials that are resistant to chemical abrasion and damage.

Food and Beverage

Film hoses are used in the food and beverage industry. They are used for the transportation of water, food products, and other liquids. They are FDA-compliant and are manufactured using non-toxic materials.

HVAC Systems

These hoses are used in heating, ventilation, and air conditioning (HVAC) systems. They are used for the transportation of refrigerants, water, and air. Their lightweight and flexible nature makes them ideal for use in HVAC systems.

Firefighting

Film hoses are used in firefighting applications. They are used to transport water to fire sites and are used in fire sprinkler systems. Their ability to withstand high pressure makes them ideal for firefighting applications.

Choosing the right PVC film hose for specific applications requires careful consideration of several factors to ensure optimal performance, longevity, and safety. Here are some key factors to keep in mind:

Diameter and Length

The hose's diameter and length will affect fluid flow, pressure drop, and compatibility with the intended application. A wider film hose is ideal for applications demanding high flow rates, while a more narrow hose reduces fluid waste and improves pressure. PVC film hoses come in different lengths suitable for various applications. When shopping for these hoses, it is important to determine the right length that will adequately meet system requirements.

Working Temperature and Pressure

It is important to check the temperature and pressure rating of the PVC film hose to ensure it can withstand the specific conditions of the intended application. Choosing a hose with a compatible rating prevents hose failure, leaks, or bursts.

Compatibility with Liquids/Gases

Ensure the film hose material is compatible with the type of liquid or gas it will transport. For example, some materials are better suited for handling corrosive substances or abrasive particles.

Reinforcement

If the application requires high pressure or a vacuum, choose a hose with appropriate reinforcement, such as braided or spiraled textiles. Reinforced film hoses provide extra strength and durability.

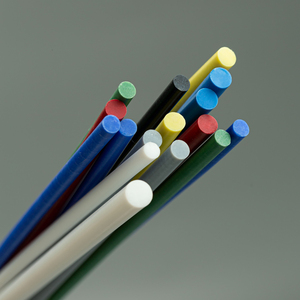

Quality of Material

Ensure the hose is made from high-quality materials, such as elastomers or reinforced plastics. This guarantees adequate flexibility, transparency, and improved performance.

Certifications and Standards

Always choose a PVC film hose that meets relevant industry standards and certifications for quality assurance and safety. This guarantees reliable performance.

Cost vs. Value

While the initial cost is an important consideration, focus on the long-term value by assessing the hose's lifespan, maintenance needs, and performance. A higher-quality hose may have a higher upfront cost but can save money over time.

Q1: What is a film hose?

A1: A film hose is a flexible plastic tubing that filmmakers use to transport liquids or gases for special effects, stunts, and other film-related tasks.

Q2: What are the types of film hoses?

A2: There are several types of film hoses, including PVC layflat hoses, fire hoses, bull hoses, canvas hoses, and hydraulic hoses.

Q3: What are the applications of film hoses?

A3: Film hoses are used in various applications, such as transporting water in stunts, creating rain or water effects, fueling vehicles and machinery, and transporting liquids in the film industry.

Q4: What are the key considerations when choosing a film hose?

A4: Consider the film hose's durability, flexibility, diameter, length, and compatibility with the transported liquid or gas.

Q5: How should a film hose be maintained?

A5: A film hose should be cleaned after use, properly stored to prevent kinks and damage, and regularly inspected for wear and tear.