(4601 products available)

Hino J08E-UN

) The Hino J08E-UN is a very popular engine. It is known for its strong power and high torque. Most of the time, it is used for heavy-duty work. The Hino J08E-UN engine has a high power output and strong pulling strength. It can be found in many trucks and buses. It is mostly used in places where a lot of load needs to be carried. In addition, the Hino J08E-UN engine has a good reputation for being reliable and lasting a long time. Many people use it in difficult places where the engine must work hard all day long. The Hino J08E-UN engine uses diesel fuel. Diesel engines are very efficient for long distances and heavy loads.Hino J08E-VC

) The Hino J08E-VC engine is also known as the Hino J08E Variable Common Rail Diesel Engine. It has a very advanced technology of common rail diesel fuel injection system. The common rail system provides precise control of fuel delivery. It helps improve combustion efficiency and increases power output while reducing emissions. The Hino J08E-VC engine can meet strict environmental standards. It uses a selective catalytic reduction (SCR) system to reduce nitrogen oxide emissions. The SCR system injects urea into the exhaust stream. It reacts with NOx and converts it into nitrogen and water vapor. The J08E-VC engine also has a diesel particulate filter (DPF) installed. The DPF captures and removes soot and particulate matter from the exhaust. This helps lower PM emissions from the engine. Overall, the Hino J08E-VC engine adopts many innovative design elements to achieve higher performance with lower environmental impact.Hino J08E-TX

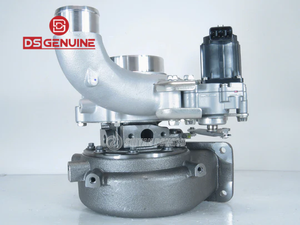

) The Hino J08E-TX engine is a turbocharged inline 6-cylinder diesel engine. It has the same basic configuration as other J08E engines. For instance, the 6-cylinder layout with 6 cylinders arranged in a line, and the DOHC design with 2 camshafts, 1 for each of the 6-cylinder banks. But the -TX variant has a turbocharger added. The turbocharger uses exhaust gases from the engine to spin a turbine. This turbine draws in air and forces more oxygen into the engine cylinders. As a result, the Hino J08E-TX engine can capture more power from the same amount of fuel. The main benefit is higher power output without increasing engine size. The -TX variant's turbocharging enables Hino to meet rising power demands while maintaining engine compactness. Other features like intercooling and variable turbine geometry further enhance the J08E-TX engine's forced induction efficiency. Overall, the Hino J08E-TX turbocharging technology exemplifies innovative engineering to optimize diesel power delivery.Regular oil changes

Engine oil lubricates the internal components of the Hino J08E engine to reduce friction and wear. Oil and filter changes should be performed as recommended in the owner's manual or more frequently if the vehicle operates under severe conditions such as towing, hauling, or driving in extreme temperatures. Fresh oil also helps keep contaminants suspended so they can be filtered out.

Cooling system service

Regularly checking and maintaining the cooling system is critical for preventing overheating of the Hino J08E engines. The coolant level should be topped off, and the hoses, pump, and radiator should be inspected for leaks or damage. The coolant itself should be replaced at the intervals specified in the owner's manual, usually every few years. This ensures it can effectively transfer heat and protect against freezing or corrosion.

Air intake and filter

Hino J08E engines draw air through an intake system that includes a filter. This filter needs to be checked regularly, typically every few months or at least with each oil change. It should be inspected for excessive dirt buildup and replaced as needed, usually every 30,000 to 60,000 miles. A clean air filter is important for optimal engine performance and fuel efficiency.

Regular inspections and tune-ups

Owners should adhere to scheduled maintenance inspections and tune-ups that include checking spark plugs, ignition components, valves, timing belts, and other major parts of the Hino J08E engine. The intervals for these services are specified in the owner's manual. In addition, a professional technician can easily identify any developing issues before they become major problems and ensure everything operates within factory specifications.

Fuel system maintenance

The fuel filter in the Hino J08E engine should be inspected and replaced regularly to prevent dirt and water from clogging it. On diesel engines, water accumulates in a separator and must be drained periodically, usually every oil change or more frequently in wet conditions. Keeping the fuel system clean helps maximize fuel delivery and efficiency.

Exhaust system inspection

The exhaust system, including the muffler and catalytic converter, should be inspected for damage, rust, or leaks. The components are important for emissions control and noise reduction. Any issues found should be addressed promptly so the exhaust system can function properly.

Choosing the right Hino J08e engine for a business needs involves understanding several key factors to ensure it meets operational requirements. Here are some significant considerations:

Understanding Business Needs

Consider the business type and its operational needs. A logistics company may require higher power and torque for long-haul trucks, while a construction company may need more robust engines for off-road capabilities.

Load Capacity

The chosen engine must have enough power to handle the expected load. Overloading can lead to faster engine wear and increase the risk of mechanical failures.

Fuel Efficiency

For long-term cost-effectiveness, consider the engine's fuel efficiency. A more fuel-efficient engine may have a higher upfront cost but can lead to significant savings over time.

Maintenance and Reliability

The engine's reliability and the availability of maintenance services and spare parts are crucial considerations. A reliable engine reduces downtime, while accessible maintenance services ensure timely repairs.

Environmental Regulations

Ensure that the chosen engine meets local environmental regulations regarding emissions. Some regions offer incentives for using low-emission or alternative-fuel engines.

Cost

Consider the initial purchase price, but also take into account the total cost of ownership, including fuel, maintenance, insurance, and potential resale value. Sometimes, an engine with a higher initial cost may be more economical in the long run.

Replacing the Hino J08E engine can be a complex task, but with the right tools and knowledge, it can be done. Here is a step-by-step guide on how to replace the Hino J08E engine:

Before starting the replacement process, it is important to have the following tools and materials ready:

Step 1: Preparation

1. Disconnect the battery: Start by disconnecting the battery to avoid any electrical accidents during the replacement process.

2. Drain the fluids: Drain all the fluids from the old engine, including the engine oil, coolant, and fuel. Use an oil drain pan to collect the drained fluids.

3. Remove the electrical connections: Disconnect all the electrical connections from the old engine. Take note of where each connection goes to make it easier to connect them to the new engine.

4. Remove the cooling system: Disconnect the cooling system from the old engine. This includes removing the hoses and clamps.

Step 2: Removing the Old Hino J08E Engine

5. Remove the air intake system: Take out the air intake system from the old engine. This includes removing the air filter and intake manifold.

6. Remove the exhaust system: Disconnect the exhaust system from the old engine. This includes removing the exhaust manifold and pipes.

7. Remove the engine mounting bolts: Use a socket and wrench set to remove the engine mounting bolts that secure the old engine to the chassis.

8. Lift the old engine out: Use an engine hoist to lift the old engine out of the chassis. Be careful not to damage any surrounding components during this process.

Step 3: Installing the New Hino J08E Engine

9. Mount the new engine: Use the engine hoist to place the new engine onto the chassis. Ensure it is properly aligned with the mounting points.

10. Secure the engine: Use the socket and wrench set to install the engine mounting bolts and secure the new engine to the chassis. Tighten the bolts to the manufacturer's specifications using a torque wrench.

11. Reinstall the exhaust system: Connect the exhaust system to the new engine. This includes installing the exhaust manifold and pipes.

12. Reinstall the air intake system: Connect the air intake system to the new engine. This includes installing the air filter and intake manifold.

Step 4: Final Steps

13. Reconnect the cooling system: Connect the cooling system to the new engine. This includes installing the hoses and clamps.

14. Reconnect all electrical connections: Reconnect all electrical connections to the new engine. Refer to the notes taken during the disconnection process.

15. Fill the engine with new oil: Pour new engine oil into the new engine using the oil filler cap. Ensure the oil level is within the recommended range on the dipstick.

16. Fill the cooling system with coolant: Pour coolant into the cooling system of the new engine. Ensure there are no leaks and the coolant level is within the recommended range.

17. Reconnect the battery: Reconnect the battery to power the electrical systems of the new engine.

18. Start the engine: Turn the key to start the new engine. Let it run for a few minutes and check for any unusual sounds or leaks. Ensure everything is working properly.

By following these steps, one can successfully replace the Hino J08E engine. However, if unsure or uncomfortable with any part of the process, it is always best to consult a professional mechanic for assistance.

Q1: How do I know if the Hino J08e engine is good for my vehicle?

A1: The appropriateness of the Hino J08e engine for a vehicle depends on various factors, including the vehicle's size, weight, and intended use (such as city driving, highway driving, or off-road). The Hino J08e engine is known for its durability and efficiency, making it suitable for commercial vehicles that require heavy hauling or transportation of goods. If the vehicle is a commercial one, the Hino J08e engine should be a good fit.

Q2: What are the common problems associated with the Hino J08e engine?

A2: Like any other engine, the Hino J08e engine can experience problems. However, it's essential to note that many of these issues can be avoided with regular maintenance. Some problems that have been reported include overheating, oil consumption, and fuel system issues. If any of these problems are suspected, having a qualified mechanic check the engine as soon as possible is essential.

Q3: How does the Hino J08e engine compare to other engines in terms of fuel efficiency?

A3: The Hino J08e engine is designed to be fuel efficient, especially for an 8-liter engine. Its fuel efficiency is competitive with other engines of similar size. However, actual fuel efficiency can vary depending on driving habits, vehicle maintenance, and load size.

Q4: What is the lifespan of the Hino J08e engine?

A4: The lifespan of the Hino J08e engine can be influenced by various factors, such as driving conditions, regular maintenance, and engine load. Generally, with proper maintenance and care, the Hino J08e engine can last for several hundred thousand miles (or kilometers).

Q5: Is the Hino J08e engine a good choice for heavy-duty tasks?

A5: Yes, the Hino J08e engine is a good choice for heavy-duty tasks. It is designed to be powerful and efficient, making it suitable for tasks such as hauling heavy loads or transporting goods over long distances. Its durability and reliability are significant advantages for business operations that require heavy-duty performance.