(31548 products available)

![TS <strong>Filter</strong> Supply [Lab Membrane] Nylon PVDF PTFE Etc Microfiltration Membrane <strong>Disc</strong> <strong>Filter</strong> 13/25/47/50/54/90/142/150/293/300mm](http://s.alicdn.com/@sc04/kf/H1403aa40234342dd8b2f2a417986ee72r.png_300x300.jpg)

![TS <strong>Filter</strong> Supply [Lab Membrane] Nylon PVDF PTFE Etc Microfiltration Membrane <strong>Disc</strong> <strong>Filter</strong> 13/25/47/50/54/90/142/150/293/300mm](http://s.alicdn.com/@sc04/kf/H9c38fe8a11e743df98345b90bf3537fby.jpg_300x300.jpg)

![TS <strong>Filter</strong> Supply [Lab Membrane] Nylon PVDF PTFE Etc Microfiltration Membrane <strong>Disc</strong> <strong>Filter</strong> 13/25/47/50/54/90/142/150/293/300mm](http://s.alicdn.com/@sc04/kf/H6723fbefda97441cb1a0b1ba04737464Q.jpg_300x300.jpg)

![TS <strong>Filter</strong> Supply [Lab Membrane] Nylon PVDF PTFE Etc Microfiltration Membrane <strong>Disc</strong> <strong>Filter</strong> 13/25/47/50/54/90/142/150/293/300mm](http://s.alicdn.com/@sc04/kf/H4dfddb99996c4de3a816b5bb0f941038g.jpg_300x300.jpg)

![TS <strong>Filter</strong> Supply [Lab Membrane] Nylon PVDF PTFE Etc Microfiltration Membrane <strong>Disc</strong> <strong>Filter</strong> 13/25/47/50/54/90/142/150/293/300mm](http://s.alicdn.com/@sc04/kf/H272660ad3b5547d1b9d4a45a58f0db90b.jpg_300x300.jpg)

![TS <strong>Filter</strong> Supply [Lab Membrane] Nylon PVDF PTFE Etc Microfiltration Membrane <strong>Disc</strong> <strong>Filter</strong> 13/25/47/50/54/90/142/150/293/300mm](http://s.alicdn.com/@sc04/kf/H8d5ad01cca1d4288b59286fd30d86cbdt.png_300x300.jpg)

Disc filters are used to filter out unwanted particles from liquids and gases in industrial applications. They are made by stacking several discs, each with a perforated pattern, on top of each other. The type of disc filter is determined by the material used to make the discs and the general design of the filter. There are various ways to classify disc filters, but the most common ones include material composition, mechanical arrangement, and application-based classifications.

Classification Based on Material Composition

This classification categorizes disc filters based on the materials used to manufacture the filter discs.

Fabric Disc Filters: Fabric disc filters are made from woven synthetic fabrics like nylon or polyester. They are suitable for filtering slurries and suspensions and can be cleaned and maintained easily. The woven fabric provides a large surface area for filtration.

Wire Mesh Disc Filters: Wire mesh disc filters are made using stainless steel or bronze wire mesh. They are robust and can withstand high pressures and temperatures. They are suitable for applications where strong and durable filters are required.

Ceramic Disc Filters: Ceramic disc filters have discs made of porous ceramic materials. They are used for fine filtration in industries like pharmaceuticals and food processing. Ceramic filters can withstand high temperatures and aggressive chemicals.

Polypropylene Disc Filters: Polypropylene disc filters have discs made from polypropylene, a lightweight and chemical-resistant plastic material. These filters are used in water treatment and aquaculture. They are corrosion-resistant and suitable for filtering chemicals and wastewater.

Glass Fiber Disc Filters: Glass fiber disc filters have discs made from compressed glass fibers. They are used for fine filtration in laboratories and environmental monitoring. Glass fiber filters have high dirt-holding capacity and can be disposed of in an environmentally friendly manner.

Classification Based on Mechanical Arrangement

This classification focuses on how the filter discs are arranged and supported within the disc filter assembly.

Vertical Disc Filters: In vertical disc filters, the filter discs are arranged vertically. The vertical orientation allows gravity to assist in the filtration process. Vertical disc filters are compact and require less floor space, making them suitable for applications with limited space requirements.

Horizontal Disc Filters: Horizontal disc filters have the filter discs arranged horizontally. The horizontal orientation allows for a more even distribution of the liquid or slurry over the filter discs. Horizontal disc filters are easier to clean and maintain. They are suitable for large-scale industrial applications.

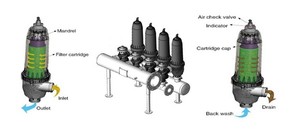

Stacked Disc Filters: Stacked disc filters have multiple filter discs stacked on top of each other. The stacked arrangement increases the filtration surface area within a compact design. Stacked disc filters are suitable for filtering high-flow rates of liquids or gases in confined spaces.

Rotary Disc Filters: Rotary disc filters have a rotating mechanism that continuously rotates the filter discs. The rotation prevents cake formation and allows for constant removal of the filtered solid material. Rotary disc filters are suitable for processes that produce large quantities of solid waste.

Classification Based on Application

This classification focuses on the specific applications and industries where disc filters are used.

Wastewater Treatment Disc Filters: Wastewater treatment disc filters are used in municipal and industrial wastewater treatment plants to remove suspended solids, dirt, and debris from wastewater before it is discharged into water bodies. These filters help in recycling and conserving water resources.

Aquaculture Disc Filters: Aquaculture disc filters are used in fish farming operations to keep the water clean by removing solid waste and uneaten feed particles. Clean water is essential for fish health and growth.

Irrigation Disc Filters: Irrigation disc filters are used in agricultural irrigation systems to filter out particles from water sources like rivers or ponds. Clean water prevents clogging of irrigation pipes and emitters, ensuring even distribution of water to crops.

Food and Beverage Disc Filters: Food and beverage disc filters are used in the food processing industry to filter juices, oils, and other products. The filters remove impurities, ensuring product safety and quality. Clean filters are essential for maintaining the taste and appearance of food and beverages.

Mining Disc Filters: Mining disc filters are used to separate solid particles from slurry in mineral processing. They improve the recovery of valuable minerals and reduce the environmental impact of tailings disposal.

The design of disc filters is simple, yet they have a lot of advantages over other filtering systems. They are made to be compact and efficient so that they can be used in different agricultural settings.

In summary, the design of disc filters focuses on simplicity and efficiency. They are compact and modular, can remove different kinds of dirt, and have a high dirt-holding capacity. Thus, disc filters are a reliable and long-lasting solution for keeping irrigation systems clean and working well.

Disc filters for irrigation systems work for several applications. They are versatile and efficient in removing unwanted materials in different industries. These applications show how well disc filters work in different filtering demands.

Agriculture

Disc filters are widely used in agriculture. They remove dirt, sand, and other debris from the irrigation water. This keeps the drips and sprinklers from clogging. Farmers use disc filters to ensure that their plants get clean water. This is essential for healthy plant growth. They are also used in fertigation systems. The clean water prevents clogging of fertilizer injectors.

Aquaculture

Aquaculture farms rely on disc filters to provide a clean water supply to fish and shrimp. The filter removes feed pellets, fish waste, and other organic material from the water. This gives the aquatic animals a healthy living environment. It also helps maintain water quality and reduces disease risk.

Industrial Water Treatment

Many industries use disc filters in their water treatment systems. The filters remove large particles before the water goes through other treatment processes. They are also used to recycle water in industries like textile and food processing. This saves water and reduces wastewater discharge.

Stormwater Management

In urban areas, disc filters manage stormwater runoff. They clean the water before it goes into natural water bodies. This protects the environment from pollution. The filters remove trash, soil, and chemicals from stormwater. Some designs allow for easy cleaning and maintenance, making them suitable for retaining debris.

Groundwater Recharge

Disc filters are used in groundwater recharge projects. They clean the water that goes into the ground. This helps protect the aquifer from pollution. The filters are vital in areas with water scarcity. They ensure that only clean water replenishes the groundwater supply.

Desalination Plants

Desalination plants use disc filters to clean seawater before the desalination process. The filter removes large particles and organic materials. This protects the reverse osmosis membranes and improves the efficiency of salt removal.

Choosing the right disc filter is important to ensure that the filtering system works efficiently. To choose the right filter, consider the following factors:

Q1: What are the benefits of disc filters?

A1: Disc filters are compact and have a large filtration area. They can filter out various sizes of particles and are easy to clean and maintain.

Q2: How does the automatic backwashing feature work?

A2: The system automatically reverses the flow of water through the filter element to dislodge and remove trapped debris.

Q3: What materials are commonly used in disc filters?

A3: Many disc filters are made from polypropylene, stainless steel, or brass, among other materials.

Q4: Can disc filters be used for different types of liquids?

A4: Yes, disc filters can be used for various liquids, including water, chemicals, and oil. However, compatibility with the liquid must be considered.

Q5: What maintenance do disc filters require?

A5: Regular inspection, cleaning of the filter elements, and replacement of worn parts are necessary for the maintenance of disc filters.