(7143 products available)

Diamond core cutters are primarily used for making clean and precise holes in a variety of hard materials like concrete, granite, glass, ceramic, and metal. One of the reasons they are widely used in the construction industry and for stonework is their toughness and accuracy. Here are the main types:

This type is mostly used by those who drill into concrete blocks, bricks, and mortar. Its segments have diamonds embedded in a metal bond, allowing it to cut hard materials. For drilling large holes in masonry work, this cutter is ideal.

These segments differ in that wet cutters need cooling with water while dry ones do not. Wet diamond core drill bits help reduce heat and remove dust when cutting, giving a better finish. They are ideal for drilling materials like reinforced concrete, natural stone, and porcelain tiles. In locations where water is not available, the dry diamond core drill bits work well. They have a vacuum weld that holds the diamond better than the wet cutters. They are mostly used for quick jobs on various materials and when working indoors.

These core cutters, often used in manufacturing or tiling work, have diamonds attached to their tips. This allows them to cut smoothly into fragile materials. An advantage is that they won't chip the edges of glass or tiles as they cut, which is important for clean pieces.

These cutters are used in metal fabrication or construction work. They can cut holes in sheets of steel, aluminum, and copper. Their diamond tips let them easily slice through tough metal surfaces. There are also special diamond core drills for hard metals. These drills have more diamonds and tougher bonds for precise cuts in demanding tasks.

It is important to know the material and use of the diamond core cutters in order to choose the right core cutter. The main points to consider are material, size, bond strength, water cooling, and the power of the drill to keep the core cutter rotating.

To get the best results from diamond core cutters, it helps to follow some simple steps. The first step is to ensure that the core cutter is securely attached to the drill. If using a wet cutter, water must be turned on to keep the bit cool. For a dry cutter, the drill can be turned on right away. The drill should then be slowly pushed to make contact with the material. This helps keep the bit from breaking. The drill should be used at a steady speed without too much pressure. It helps the diamonds cut through the material.

If the bit starts to get hot, more water or a pause can help cool it down. When the hole is finished, the core should be removed from the cutter. Light tapping with a soft mallet helps separate it. Clean the cutter by rinsing away any stuck pieces. This helps it stay sharp for longer. A soft brush can be used to get into small spots. Storing the cutter in a dry place keeps it from rusting or wearing out.

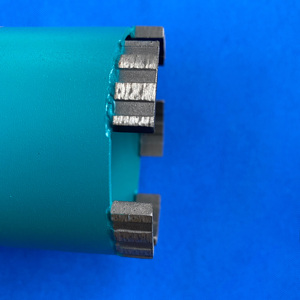

As for the product, a core cutter is a small tool that makes holes in materials like stone or concrete. It looks like a tiny tube or cylinder. The outside edge has tiny diamond pieces stuck on it. These diamonds help the cutter slice through really hard things. Most core cutters are made from strong steel. The diamond part is extra tough, so it won't wear down while cutting. Some core cutters also have water channels. These let water wash away dust and keep the cutter cool. Core cutters come in different sizes. Smaller ones make little holes, and bigger ones create wide holes. They are used by construction workers, tile installers, or artists cutting stone. The diamond core cutter is a helpful tool. It cuts clean holes for many projects.

A1: It makes clean holes in hard materials like concrete, granite, glass, and metal.

A2: A diamond core bit can last from weeks to several years depending on the material and how it is used.

A3: They are used to cut smooth holes in tough surfaces like stone, concrete, and glass.

A4: Unlike hole saws, core bits remove a round piece from the material to create deeper and cleaner holes.

A5: It is important for diamond bits. Water or other coolants keeps the bit from overheating during drilling.