Introduction to CNC Carbide Threading Inserts

CNC carbide threading inserts are precision-engineered tools designed for threading operations in various machining applications. These inserts, made from high-quality carbide material, provide exceptional durability and performance, making them a preferred choice among manufacturers and machinists. With their ability to cut through tough materials, CNC carbide threading inserts enhance productivity and precision in any machining environment.

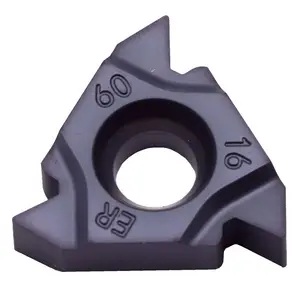

Types of CNC Carbide Threading Inserts

CNC carbide threading inserts come in a variety of shapes and sizes, specially designed to cater to different threading requirements. Understanding these types can significantly impact your machining efficiency:

- Standard Threading Inserts: Used for common threading applications, offering versatility in operations.

- Multi-Thread Inserts: Designed for multi-start threads, these inserts allow for faster production rates.

- Fine Pitch Inserts: Ideal for creating finer threads with tighter tolerances.

- Grooving Inserts: Suitable for creating grooves along with threading, enhancing the machining capabilities.

Applications of CNC Carbide Threading Inserts

The functionality of CNC carbide threading inserts extends across various industries due to their adaptability and performance:

- Automotive Manufacturing: Used extensively in engine parts and transmission assemblies.

- Aerospace: Crucial in producing lightweight, high-strength components for aircraft.

- Machine Tool Industry: Essential for creating precision components that require high levels of accuracy.

- Oil and Gas: Employed in drilling operations where reliable threading is critical for performance.

Advantages of CNC Carbide Threading Inserts

Utilizing CNC carbide threading inserts presents numerous advantages that contribute to their popularity in the machining sector:

- Enhanced Durability: Carbide material provides superior resistance to wear and heat, ensuring prolonged tool life.

- Improved Surface Finish: The precision design of the inserts ensures a smooth surface on the threaded components, enhancing overall quality.

- Higher Cutting Speeds: CNC carbide inserts allow for swift machining operations, reducing cycle times and increasing productivity.

- Cost-Effectiveness: Despite the initial investment, the longevity and efficiency of carbide inserts lead to overall savings in tooling costs.

Function, Feature, and Design of CNC Carbide Threading Inserts

The functional aspect of CNC carbide threading inserts revolves around their design and features that facilitate efficient machining:

- Precision Cutting Geometry: Designed with optimal cutting angles, CNC carbide threading inserts improve chip evacuation and reduce cutting forces.

- Interchangeable Systems: Many of these inserts feature a modular design, allowing easy replacement and minimizing downtime during operations.

- Variety of Coatings: Available with specialized coatings like TiN or TiAlN, these inserts offer additional hardness and thermal stability.

- Compatibility with Multiple CNC Machines: Their versatility means they can be utilized across various CNC lathe systems, enhancing operational flexibility.