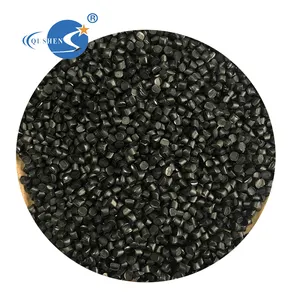

Introduction to Cling Masterbatch

Cling masterbatch is a specialized additive used in the plastic industry, essentially designed to improve the cling properties of plastic films. This innovative product plays a crucial role in the production of a variety of cling films and wraps, helping to enhance their performance in packaging applications. The key to cling masterbatch lies in its ability to reduce the surface energy of plastics, thus creating an effective cling effect that holds the materials together securely.

Types of Cling Masterbatch

Cling masterbatch comes in various formulations to cater to different applications and plastic types. The following are the primary types:

- Polyethylene-based Cling Masterbatch: Ideal for low-density polyethylene (LDPE) films, commonly found in food packaging.

- Polypropylene-based Cling Masterbatch: Suitable for stringent cling requirements in polypropylene films, widely used in pre-packed products.

- High-performance Cling Masterbatch: Advanced formulations designed for multi-layer applications that require superior performance and stability.

- Biodegradable Cling Masterbatch: Eco-friendly options available for manufacturers committed to sustainability without compromising cling performance.

Applications of Cling Masterbatch

Cling masterbatch is versatile and finds its applications across various industries. Here are some of the prominent uses:

- Food Packaging: Essential for producing wraps that maintain freshness and extend the shelf life of food products.

- Industrial Packaging: Utilized in secure packaging solutions for goods requiring protection during transport and storage.

- Consumer Products: Employed in cling films, stretch films, and shrink wraps to enhance user convenience and product presentation.

- Medical Supplies: Used in sterile packaging to ensure safety and efficacy in healthcare products.

Advantages of Cling Masterbatch

Using cling masterbatch offers several benefits that can enhance the overall performance of plastic films:

- Improved Performance: Provides superior cling properties, ensuring that films stick together securely without the need for adhesives.

- Enhanced User Experience: Offers convenience in packaging, allowing consumers to access the product easily without difficulty.

- Customizable Formulations: Can be tailored to meet specific requirements of different industries, ensuring optimal performance.

- Cost-effective: Reduces waste by improving reusability and extendability of plastic films, translating to overall savings for manufacturers.

- Environmentally Friendly Options: The availability of biodegradable cling masterbatch serves to address the growing demand for sustainable solutions in the plastic industry.