(1371 products available)

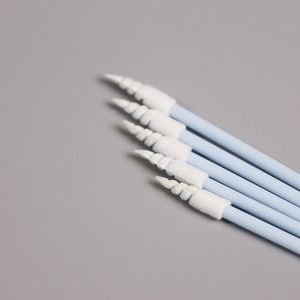

A cleanroom foam tip swab has a long plastic handle with a foam tip on one end. The tip is usually white and can be square or cylindrical. The other end has a firm plastic handle. Some swabs have a short, pointed tip to access small areas. The swab is packaged in a cleanroom environment, so it is ready for use in controlled areas.

The different types of cleanroom foam swabs include the following:

When selecting appropriate cleanroom foam tip swabs, several factors must be considered to ensure the right product for a particular application. Here are some essential tips for choosing the suitable cleanroom foam tip swabs:

Tip material and shape:

The tip's material and shape are crucial in determining the effectiveness of the foam tip swab for a particular application. The foam material used will impact debris removal, solution retention, and particle transfer. For instance, open-cell polyurethane foam is an excellent choice for general-purpose cleaning due to its high absorbency and retention properties. In contrast, closed-cell PVC foam offers superior abrasion resistance and is better suited for scrubbing applications. Additionally, the shape of the tip, whether cylindrical, flat, or tapered, can affect access to tight spaces and the swab's cleaning efficiency. Therefore, one must consider the material and shape of the tip when selecting a foam tip swab to ensure optimal performance and desired application outcomes.

Handle length and material:

The handle length and material of a foam tip swab are important considerations when selecting the right product for a particular application. The handle length determines how easily the swab can reach tight spaces or areas that require cleaning. A longer handle may be needed for deep recesses, while a shorter handle is more maneuverable for shallower areas. The handle material also impacts the swab's strength and durability. Rigid plastic handles offer sturdiness but may not flex in tight curves; flexible materials like PVC can bend without breaking. Understanding the application requirements regarding reach and handle characteristics helps choose a foam tip swab that performs efficiently and lasts longer.

Packaging and quantity:

Cleanroom foam tip swabs are often packaged in quantities that suit the needs of different applications and environments. For instance, bulk packaging is ideal for facilities with high swab usage, such as manufacturing cleanrooms or laboratories, as it provides cost savings and convenience. On the other hand, smaller, more precise packaging may be appropriate for occasional use or specific projects where swabs are needed in limited numbers. In cleanroom environments, maintaining the integrity and contamination-free status of the swabs is vital; hence, the type of packaging—whether bagged, heat-sealed, or clamshell—also plays a role in ensuring they meet stringent cleanliness requirements before use. Buyers should consider both quantity and packaging to optimize cleanliness and cost-effectiveness in their operations.

Using foam tip swabs in cleanrooms ensures no contamination from the tools. Here are some tips for using them:

Prepare the Area

Make sure the work area is clean and free of any unnecessary items or equipment. Wipe down surfaces with appropriate cleaning agents.

Gown Up

Put on all the required cleanroom garments, including gloves, bouffant caps, masks, and shoe covers. Make sure garments are properly fitted to avoid exposing skin and hair.

Open the Package Properly

Carefully open the foam tip swab package while avoiding excessive handling of the swab. Do not touch the foam tip, which will come into contact with samples or surfaces that need to be cleaned.

Avoid Contamination

Do not touch the foam tip or expose it to unclean surfaces. Hold the swab by the handle and use it promptly after removal from its packaging.

Use Gentle Pressure

When using the swab, apply only gentle pressure to avoid crushing the foam tip, which could release contaminants. Use the required motion or action to clean or sample the desired area.

Dispose of Swabs Properly

Foam tip swabs are single-use, so throw them away in the designated waste container for cleanroom debris. Do not attempt to reuse the swab, as this could risk contamination and compromise the cleanroom's integrity.

Using foam tip swabs in cleanrooms is safe when users follow the guidelines. Here are some of the product's safety features:

Single-Use Design

The swabs are single-use only, which means that any chance of contamination is minimized. This helps maintain the integrity of the cleanroom.

Controlled Packaging

Swabs come in controlled packaging that keeps them safe from outside contaminants. The packaging is only opened in the cleanroom and right before using the swab.

Low Particulate Generation

Swabs are specially made to produce foam for clean rooms and generate low particles. This feature is vital in environments requiring strict compliance with cleanliness standards.

Non-Abrasive Foam Tips

The foam tips are non-abrasive, which means they won't damage sensitive surfaces or equipment. This is important when cleaning or sampling delicate components.

Compatible Materials

The materials used in making the swabs are compatible with various cleanroom chemicals and won't react with them. This ensures the foam swabs won't degrade or release contaminants when exposed to cleaning agents or disinfectants.

Cleanroom foam tip swabs are indispensable tools that have been designed to meet the requirements and specifications of cleanroom environments. They do this while offering functionality, durability, and versatility.

Some of the functions, features, and designs of cleanroom foam tip swabs include the following:

Q1: What are cleanroom foam tip swabs?

A1: Cleanroom foam tip swabs are specialized small tools with a handle and a foam tip used for cleaning and applying substances in controlled cleanroom environments. They have handles made of plastic or wood and foam tips that are dense and porous, allowing for minimal liquid absorption and efficient application.

Q2: What materials are used to make cleanroom foam tip swabs?

A2: The materials used to make cleanroom foam tip swabs are polypropylene, polyurethane, and polystyrene. Polypropylene is used to make the plastic handles because it is a durable and non-biodegradable plastic. The foam tips are made of polyurethane because it is a low particle-emitting material suitable for cleanroom environments. Polystyrene is a rigid plastic used to make the shaft of the swabs.

Q3: Are cleanroom foam tip swabs reusable?

A3: Some cleanroom foam tip swabs are reusable, while others are not. The reusable ones can be washed and dried for future use, unlike the disposable ones, which cannot be washed and are only single-use. However, thoroughly washing the reusable swabs is essential to ensure no contaminants remain on them.

Q4: How should cleanroom foam tip swabs be stored?

A4: Cleanroom foam tip swabs should be stored in a cleanroom storage area to keep them free from any contaminants. They should be stored in their packaging or in a designated container that is clean and dust-free. Proper storage helps maintain their cleanliness and suitability for use in cleanroom applications.

Q5: Can cleanroom foam tip swabs be used outside cleanroom environments?

A5: While cleanroom foam tip swabs are designed for use in cleanroom environments, they can be used outside these environments for various cleaning and applicator tasks. However, their primary advantage is their low-contaminant design, which makes them suitable for use in applications where contamination control is critical.