(2825 products available)

Ready to Ship

Ready to Ship

A cleaning foam swab is a small stick with a soft, absorbent foam tip. It is mainly used to clean delicate parts of electronic devices. The following are the types of cleaning foam swabs:

Rectangular Foam Tip Swabs

Rectangular foam tip swabs have a square or rectangular head. The head is usually large and flat, with rounded edges. This makes it good for cleaning dusty areas or large surfaces. The foam tip is soft and dense. It can hold a lot of cleaning liquid and has good abrasion resistance. The stick is made from high-quality plastic or wood. Some have a long stick, while others have a short one. They are available in different sizes to suit various cleaning tasks.

Cylindrical Foam Tip Swabs

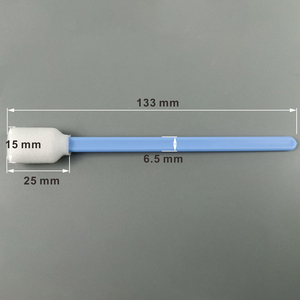

Cylindrical foam cleaning swabs are long and narrow. They are also called pointed or tapered foam swabs. The cylindrical foam cleaning swabs have a small, round foam head on one end. Some have a single foam head, while others have foam heads on both ends. The swabs work well for cleaning tight spaces, grooves, or holes. The pointed foam tip can reach deep areas. It is also gentle on the surface being cleaned. The cylindrical swab is made from strong plastic or wood. The stick's length varies from 3 to 6 inches, and the foam's diameter is between 0.5 to 1 inch.

Large Foam Swabs

Large foam swabs have a larger foam tip than regular-sized ones. They can have a rectangular or cylindrical shape. The large cleaning foam swab is on a longer stick, making it easier to use. The long stick can reach areas that are hard to access. It is frequently used in manufacturing and industrial settings. The large foam tip can cover a larger surface area and is more visible during cleaning. It is also more durable and can withstand rough handling.

Specialized Foam Swabs

Specialized foam swabs have unique features to meet specific cleaning needs. For example, some have handles that bend or flex. This makes cleaning curved surfaces easier. Others have longer handles to clean hard-to-reach places. Some swabs have reinforced handles for extra strength. Specialized cleaning foam swabs are used in places like labs, hospitals, and electronic manufacturing plants. The unique features of the swabs make them suitable for cleaning delicate equipment and surfaces.

When choosing cleaning foam swabs, one must consider a few critical factors to ensure proper selection for the required application. These factors include:

How to use and install cleaning foam swabs is simple. Below is a step-by-step guide on how to use them.

Prepare the Surface

Turn off the device and expose the area that needs cleaning. This could be a circuit board, connector, or any other part that requires thorough cleaning. Ensure that no other debris or residue might interfere with the cleaning process.

Inspect the Cleaning Foam Swab

Check the foam swab for any visible dirt or damage. Make sure the foam tip is intact and clean, as this will determine effective cleaning without leaving behind more residue.

Moisten the Foam Tip (if necessary)

If the cleaning requires a slightly dampened foam tip, moisten it with a small amount of the appropriate cleaning solution. Avoid soaking the tip, as excess liquid can damage electronic components. For dry swabs, skip this step.

Clean the Desired Area

Gently insert the foam swab into the area that needs cleaning. Don't apply too much pressure, as this might damage delicate components. Use a circular motion to clean the area. If it's excess solder, the swab can scrape gently. If it's dirt or dust, the circular motion will help remove it. If needed, the user can use a toothbrush for soldering.

Check the Foam Tip

Periodically, remove the swab and inspect the foam tip for dirt buildup. This ensures effective cleaning and prevents the transfer of grime from one area to another. If necessary, wipe it again or use a new swab.

Finish Up

Once the desired area is clean, remove the foam swab carefully. Do not drag it out, as this could smudge the cleaned area. Dispose of the swab properly if it's single-use; otherwise, clean it according to the manufacturer's instructions.

Cleaning foam swabs are safe when used as intended. Here are some tips to ensure adequate safety during use.

Read Instructions

Always read the instructions provided by the manufacturer. This will guide the user on the appropriate area to use and any precautions needed.

Use Appropriate Cleaning Solution

When using a cleaning solution, ensure it's appropriate for the materials being cleaned. Some solutions can damage specific components, so always use a recommended product.

Avoid Excessive Pressure

Excessive pressure can damage delicate electronic parts. Use gentle circular motions to avoid snapping off any fragile components.

Work in a Well-Lit Area

A well-lit area will ensure adequate visibility of the parts being cleaned. This can help prevent damage and ensure thorough cleaning.

Proper Disposal

Follow proper disposal guidelines if the foam swab is single-use. Do not attempt to clean and reuse it, as that could contaminate the area intended to be cleaned.

The design of cleaning foam swabs is what enables them to perform well in different cleaning tasks. Their main function is to remove dirt, dust, and any debris from electronic parts or delicate components. The features of this cleaning tool, such as a long handle, a soft foam tip, and a synthetic material, make it suitable for this job.

Here are the key functions, features, and designs of a cleaning foam swab:

The primary function of a cleaning foam swab is to clean and remove dirt from different surfaces. It does this effectively by taking advantage of its soft foam tip. The tip can reach tight spots, ports, and grooves and gently remove dust without scratching the surface. The swab can also absorb excess liquid and lock it within the foam for cleaning tasks that require the application of a liquid cleaning agent.

Some features make cleaning foam swabs ideal for cleaning tasks. They include:

Cleaning foam swabs come in different designs depending on the intended use. Some have a pointed tip, while others have a flat tip. Swabs with a flat foam tip are mostly used to clean larger surfaces. Those with pointed tips clean tight areas like computer ports, camera lenses, and other electronic gadgets.

Q1: What are the benefits of using foam cleaning swabs?

A1: The benefits of using cleaning foam swabs include their ability to clean delicate surfaces without causing damage, their efficient absorption and release of cleaning solutions, and their versatility in various cleaning applications. Foam cleaning swabs are particularly useful in cleaning electronic components, medical instruments, and optical devices due to their non-abrasive nature and effectiveness in removing dirt, dust, and residue. Their design allows for thorough cleaning while minimizing the risk of scratches or harm to sensitive equipment, making them a preferred choice for quality and safety in cleaning tasks.

Q2: How to use a cleaning foam swab?

A2: To use a cleaning foam swab effectively, first identify the surface or area that needs cleaning. If using a cleaning solution, gently dip or apply it to the foam tip, ensuring it is not overly saturated. Approach the surface carefully and use the swab to make soft, circular motions or follow specific grooves or lines if applicable. Avoid applying excessive pressure, as this could damage delicate components. Allow the foam tip to pick up dirt, dust, or residue and periodically check its cleanliness. Once the surface is clean, dispose of or properly clean the swab if it is reusable.

Q3: What are the disadvantages of foam swabs?

A3: Foam swabs have several disadvantages, including the potential for foam material degradation over time, which may reduce cleaning efficiency. They can sometimes be less durable than other types of swabs, such as cotton, which means they might not be suitable for heavy-duty cleaning tasks. The foam can also trap bacteria and not release them easily; therefore, they might need to be replaced more frequently than other kinds of swabs. In some cases, the foam may not provide the same level of texture as cotton, which can be necessary for certain types of cleaning or application processes.