(26954 products available)

A clay molding machine can mold clay in different shapes and forms, mainly for industrial and commercial purposes. Buyers will find the following types of clay molding machines:

Extrusion Molding Machine

This machine uses a screw to push the clay through a die. Because of the high temperature and pressure, the clay takes the die's shape. This machine is ideal for creating products like ceramic tiles, pottery, and piping.Get price for extrusion molding machine on Chovm.

Vacuum Molding Machine

The vacuum molding machine removes air from the clay by using suction to pull it into a mold. It creates complex and detailed shapes. This machine is popular in the foundry industry, where it makes metal casting molds. It is also used to make ceramic and glass products.

Jolt-Squeeze Molding Machine

This machine jolts and squeezes sand to make molds. The jolting motion distributes the sand evenly while the squeezing compresses it. With this method, the machine makes molds for metal casting. The molds are characterized by high precision and speed.

Rotational Molding Machine

This machine molds clay into a rotational motion. The motion axes heat and distributes the material evenly. The machine is mostly used to make large and hollow-shaped ceramic products. Such products include plastic parts and automotive components.

Press Molding Machine

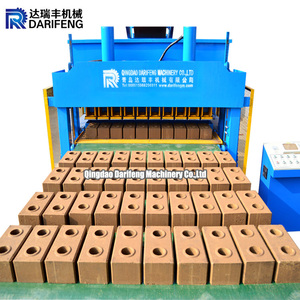

Using this machine, operators will press clay into molds. The clay takes the shape of the mold when pressure is applied. The machine makes ceramic components, pottery, and custom-designed parts with a high level of accuracy.

Isocure Molding Machine

This machine uses the Isocure process to make molds. First, a sand-resin mixture is heated in a core box. Heat activates the resin, thus forming a solid mold. The machine makes molds with high dimensional accuracy and great surface finishes. Also, it supports high production speeds.

3D Clay Printing Machines

The 3D printing machine layers clay to create three-dimensional objects. The layers harden after the clay dries. The machine is used to create architectural models, sculptures, and customized decorative pieces.

Robotic Clay Molding Machines

In this machine, robots are programmed to position and shape the clay precisely. The robotics can also be part of an automated production line. They enhance flexibility, accuracy, and efficiency in large-scale ceramic and pottery production.

The following are key specifications for a clay mold machine. They may vary according to the model and type of machine.

Mold Size

The size of the mold on the clay molding machine is set to achieve the dimensions of the clay product. The size of the mold will also depend on the nature of the final clay product.

Power Source

The clay molding machine may use different power sources. Typically, there are electrical machines that run on AC electricity, diesel-based power generation, and hydraulic clay molding machines that use the hydraulics in a heavy machine or vehicle. The power source determines how the machine connects to a power grid, vehicle, or human operator.

Production Rate

A clay molding machine will produce a certain number of molds per hour. The production rate impacts the overall productivity of the manufacturing process. Larger production rates are preferable for mass-scale production.

Machine Dimensions

The length, breadth, and height of the machine or its footprint will determine how much floor area a business has set aside for the machine. This affects the total number of machines the production facility can accommodate and the overall production capacity.

Weight

A clay molding machine weighs a certain amount. This determines the number of machines a production facility can accommodate. A heavy machine needs specialized equipment to lift it at installation sites.

Operator Controls

The clay molding machine has an operator interface with buttons, dials, and other types of controls. The operator interface determines how human-like operators interact with the machine. Modern molding machines, such as an automated clay molding machine, may have automated control operations that depend on software. In this case, the software may use artificial intelligence to improve the quality of the final clay product or increase the efficiency of production.

Material Compressed

A clay molding machine is built to work with a certain type of clay or soil. Local soil composition and geological conditions may determine the preference for a specific type of clay. Some soils require more processing expertise to extract and use them for clay products.

Vulcanized rubber, as used in the clay molding machine, has higher resilience and elasticity. It can also withstand heat and wear better than unvulcanized rubber. However, even the resilience of rubber and its excellent elasticity will fail over time. Like all mechanical machines, a clay molding machine requires periodic maintenance services to prolong its useful life.

This includes regular checking and replacing parts like rubber trays, belts, and molds. Service personnel will regularly inspect the machine to discover defects before they worsen.

Pottery workshops and art studios:

Pottery workshops and art studios represent a typical usage scenario where pottery molding machines are used. These workshops provide pottery artisans and artists with a professional workspace. Pottery molding machines assist potters in efficiently creating pottery works, such as vases, bowls, and other decorative and practical pottery items. The use of pottery molding machines in these workshops not only increases productivity but also promotes the development of pottery art.

Industrial manufacturing:

The industrial manufacturing sector is another widespread usage scenario for pottery molding machines. In the pottery manufacturing industry, pottery molding machines are employed for mass production of pottery products. These machines can quickly and efficiently mold pottery blanks, which are then baked and processed to create final pottery products. The use of pottery molding machines in industrial manufacturing enhances production efficiency and meets the demands of the market.

Product customization and development:

As technology advances, pottery molding machines are also used in product customization and development. For example, pottery molding machines can be used to mold specialized shapes and designs for artistic pottery products, as well as for prototype development and small-batch production in the fields of product design and R&D.

Educational institutions:

Pottery molding machines also play an important role in educational institutions. In ceramic art courses and vocational training programs, students learn and practice pottery making using these machines. This helps students understand the pottery-making process and enhances their practical skills. Furthermore, pottery molding machines can be used for community art activities and cultural exchange events, making pottery art accessible to a broader audience.

When purchasing a clay molding machine for sale, it is important to consider the characteristics, benefits, and drawbacks of the different types of machines in order to make an informed decision. One of the key features business buyers should look out for when buying an automatic clay molding machine or any other type is compatibility with existing production lines and materials. Buyers will want a machine that is well-integrated with their current production setup to ensure smooth, efficient operations.

Another important feature to consider is the ease of use and maintenance of the clay molding machine. In addition to being easy to operate, machines that come with intuitive control systems are also preferred. Similarly, machines that are easy to maintain will have straightforward cleaning and servicing processes. This helps to minimize downtime and keep production running smoothly. Energy-efficient machines are also worth considering as they can help reduce operating costs significantly over the long term. They also contribute to sustainable production by reducing environmental impact.

Since the quality of molded clay products is, of course, the most important selling point, buyers need to choose machines that offer flexible molding options and precise control over the molding process. Such machines allow for the customization of molds and molding parameters to achieve the desired product quality. Finally, it is also important for business buyers to consider the supplier of the clay molding machine. The ideal supplier should offer excellent after-sales service and support. This includes timely servicing and availability of spare parts.

Q1: What are the trends for clay molding machines?

A1: The trend is toward automatic molding machines, which reduce labor costs and increase production efficiency. Another trend is toward energy-efficient machines that help foundries reduce their operating costs.

Q2: How long can clay molding machines last?

A2: With proper maintenance and periodic repair, machine molds can work for over ten years.

Q3: What are the benefits of investing in a clay molding machine for business?

A3: A commercial-grade clay molding machine can increase production capacity, improve product consistency, and reduce labor costs.

Q4: What are some challenges in using clay molding machines?

A4: Some challenges include keeping the machine's moisture level, maintaining the consistency of the clay, and the learning curve associated with automated machines.