(1453 products available)

The clay machine made in china is used to manufacture a wide range of ceramic products such as flower pots, bricks, tiles, and tableware, to name a few. This machine comes with a bespoke design depending on the end product. The following are some popular clay machines and their uses.

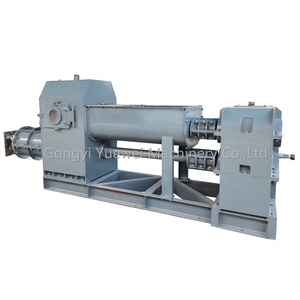

Extruder

A clay extruder machine is designed to shape and force out clay through a die in different profiles such as columns, pipe, and bars. The machine is available in both manual and automatic options and is ideal for small to medium-sized workshops. An extrusion machine consists of a hopper, auger, die, and motor. Clay is loaded into the hopper where the rotating auger pushes it forward through the die, which determines the shape of the clay. In some designs, the extruder has a movable platform so that the operator can move it closer to the workpiece.

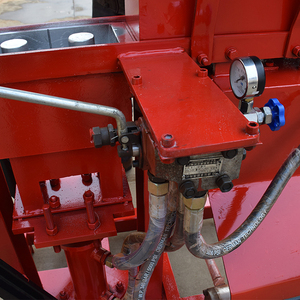

Press

A clay press machine is used to compress clay into specific shapes using a mold. This machine can be floor standing or tabletop and is suitable for producing larger tableware such as plates, bowls, and platters. The clay is compressed into a shape using a hand lever or an electric pressing tool. More modernized versions of the clay press have pneumatic or hydraulic systems for better pressure control, accuracy, and consistency.

Wheel thrower

A pottery wheel machine is used to center and shape clay into various round objects such as vases, bowls, and mugs. The speed of the wheel is adjustable when aiming to create different kinds of items. A basic pottery wheel consists of a circular wheel head, foot pedal, splash pan, and body. Advanced designs may come with programmable controls to adjust speed and time. To operate the pottery wheel, the user needs to push and pull the clay and find the ideal positioning to create the desired item. Pottery wheels can be operated manually or electrically, and pottery wheel machines made in China are usually available in one size fits all.

Jigger and Jolly Machine

This machine is commonly used to produce flat items such as plates, platters, and tiles. The clay is shaped by a rotating mold. In the Jigger machine, wet clay is pressed into a shape by a template moving down onto a stationary plaster mold. The Jolly machine works similarly, but the template moves up onto a rotating plaster mold. This machine is suitable for use in large production facilities that require consistency and high efficiency.

Requirements for a clay-making machine are as follows:

Maintenance implies a preventive approach using tools and equipment to help reduce equipment downtime. The three parts of clay machine maintenance are cleaning, lubrication, and inspection and replacement of parts.

Using clay machines, one can produce clay products for various applications.

Construction industry

Clay machines used to make bricks create more than enough raw materials for the entire construction industry. Other clay machines that ceramic and pottery businesses use also cause great challenges to construction materials.

Health industry

Vitrified ceramics produced by porcelain clay machines can be used to manufacture bioceramics that are used in joint implants. Clay machines with 3D printing features can quickly make prosthetics for the teeth.

Tableware and crockery

All kinds of clay machines are extensively used to produce tableware and crockery for domestic and commercial use. Tableware made from china, porcelain, or stoneware is still widely used today because of its durability.

Tile industry

High production capacity machines like the WANGDA Industrial Clay Extruder Machine are the go-to devices for producing ceramic tiles. Whether made from clay or porcelain, ceramic tiles remain a highly sought-after flooring option due to their durability and timeless appeal.

Sanitary ware

Machines that create sanitary porcelain are essential for the production of sanitary ware such as toilets, sink, and bidets, among other things. These items are commonly used in homes, offices, and other public facilities.

Art and design

Flexible clay machines have the capacity to create many kinds of artistic clay products like vases, sculptures, garden pots, and architectural models. The most popular flexible clay machine is the CNC machine.

Bioengineering and medical field

As noted above, advanced clay machines (such as those with 3D printing capabilities) can be utilized to make bioceramics used in bone replacement, dental implants, and hip joints. They are also employed in the production of dental crowns, bridges, and other prosthetic devices.

Educational purposes

Educational clay machines are commonly found in art schools, colleges, and recreational centers. They are used for teaching and learning purposes. Therefore, these machines help students and beginners explore and develop their creativity.

The following 8 scenarios clearly show that clay machines are an essential part of the production industry. They create all kinds of clay items for construction and other industries. Their importance cannot be overemphasized.

When purchasing clay machines for sale, buyers must get equipment that will perform and last. The following tips will help them choose the right machines.

Q1: How does a clay printing machine work?

A1: A clay printing machine works by extruding a continuous strand of clay that is deposited layer by layer in a predetermined pattern. Operators load the clay into the machine, which is then propelled by a motor-driven auger. Once the clay is properly prepared, the auger inside the container pushes it forward. The clay is then cut into specific lengths and angles and Blown through a nozzle in a specific proportion.

Q2: What are the advantages of a clay machine?

A2: The benefit of the clay machine is consistent quality in mass production. Other benefits include reducing manual labor, precise control of clay consistency, expansion of product possibilities, and time efficiency.

Q3: What is the application of the clay machine?

A3: The clay machine has different applications depending on the type of machine being used. Generally, it is used to process clay into different shapes and forms for various industries such as pottery, ceramics, architecture, and more.

Q4: Is it safe to use clay machines?

A4: Using a clay machine is generally safe as long as users follow proper safety precautions. However, a risk of injury may arise due to moving parts, heavy weight, and electrical components. It is important to be trained and follow the instructions carefully.