(613 products available)

Cheap clay machine-made bricks are mainly categorized into five types: hollow bricks, solid bricks, fly ash bricks, interlocking bricks, and CLC bricks.

Hollow bricks

Hollow bricks are designed with large, round holes or voids—and they're widely used in the construction of residential complexes, offices, and commercial establishments. The holes in each brick can either be molded or drilled, and they reduce the total volume of each brick by at least 25 percent. Hollow bricks are lighter than solid bricks, and they lower a building's overall costs and structural weight. Besides that, they provide insulation from heat and sound.

Interlocking bricks

Interlocking clay bricks are designed to fit together like puzzle pieces. They don't need cement for bonding, which simplifies installation and lowers construction costs. These bricks are eco-friendly options because they use less energy during production. Plus, they provide good thermal insulation and soundproofing effects.

Fly ash bricks

Fly ash bricks are made using fly ash, a byproduct of burning coal in thermal power plants, clay or sand, and lime. These materials are mixed together and pressed into molds using high-pressure machines. Then, they are cured using normal steam curing or autoclaved curing. Fly ash bricks are good alternatives to clay bricks, and they require less energy to make. They are lightweight, strong, and resistant to moisture, fire, and termites. They also have a low absorption rate and provide good insulation.

Cavity or hollow interlocking bricks

Cavity interlocking bricks are similar to interlocking bricks, but they have multiple voids or cavities. These cavities reduce the overall weight of each brick, making them a good option for large projects. Cavity interlocking bricks are economical, lightweight, and easy to use.

Solid bricks

Solid bricks have few or no holes, and they are manufactured in different colors. Some of them have glazed surfaces. Even though they're heavier than hollow bricks, they are stronger and more durable. Solid bricks are commonly used in load-bearing walls, boundary walls, and places that require high structural integrity.

The specifications of a clay brick-making machine may vary according to the make and model.

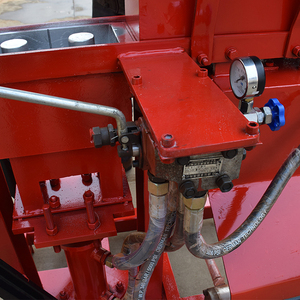

A machine will need regular maintenance so it can work well, have a long life, and make clay bricks reliably. Scheduled maintenance is necessary for the health of the brick machine and to minimize breakdowns and costly repairs. Always check the manufacturer's manual for instructions on what to check, the frequency, and the operating parameters of the machine. Here are a few general maintenance tips for all types of clay brick machines:

The clay brick making machine produces various types of bricks that can be used in many industries and applications.

Construction industry:

The construction industry is the primary market for all clay bricks. They are used to build reliable structures in residential, commercial, and industrial construction. Different types of clay bricks cater to various architectural styles and structural requirements.

Landscaping and outdoor design:

Clay bricks are widely used in outdoor landscaping and hardscaping projects. They are commonly used to create patios, walkways, garden paths, and terrace tiles. Their classic look adds architectural elegance to outdoor areas. Durable, clay bricks can withstand harsh weather conditions. Using clay bricks in outdoor spaces can increase property value.

Restoration and renovation projects:

Clay bricks are an essential component in renovation and restoration projects, particularly for historic buildings and structures. In these contexts, authenticity, integrity, and visual coherence are of paramount importance. When such factors are critical to the success of a restoration or renovation undertaking, only clay bricks can satisfy them.

Considering the following factors can aid buyers when selecting clay machine-made bricks for their intended use or investment.

Quality Control

It's crucial to choose bricks produced by a manufacturer with strict quality control at every production stage, from raw material selection and feeding to firing and cooling. This ensures uniformity in shape, size, and color and reliable performance characteristics.

Brick Type

Different machine-made clay bricks are suitable for various applications. For instance, facing bricks are aesthetically pleasing, while structural bricks offer strength. Firebricks can withstand high temperatures, and insulated bricks provide thermal insulation. Consider the specific requirements of the project and choose a brick type that meets them.

Cost

The cost of machine-made clay bricks can vary depending on the brick type, manufacturer, and quantity purchased. Calculate the total project cost, including material cost, transportation, and labor, and compare different brick options to find the most cost-effective solution.

Environmental Impact

Consider the environmental impact of the chosen brick. Some manufacturers offer machine-made clay bricks that are more environmentally friendly, such as those made from recycled materials or produced with lower energy consumption. Offsetting is a process whereby energy use in brick production is mitigated by sequestering carbon through afforestation, which can also reduce the environmental impact.

Supplier Reputation

Choose a reputable supplier with a proven track record in machine-made clay brick production. Research the supplier's experience, production capacity, and customer reviews to ensure a reliable and satisfactory purchasing experience.

Q1: How has the technology behind clay brick machines evolved?

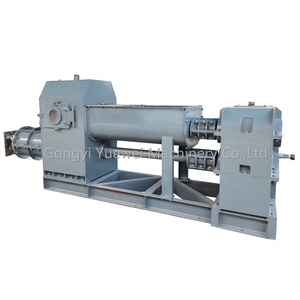

A1: The technology behind clay brick machines has evolved from manual to automated and semi-automated processes. Modern machines now use hydraulic pressure and computer-assisted design for efficiency and precision.

Q2: Are clay bricks made by machine different from those made by hand?

A2: Yes, machine-made clay bricks are generally more uniform in size and shape than handmade bricks. While both types can offer aesthetic qualities, machine-made bricks tend to be stronger due to more controlled manufacturing conditions.

Q3: What is the future of the clay brick machine market?

A3: The future looks promising, driven by urbanization, infrastructure development, and prefabricated construction trends. However, the machines will probably evolve further to use sustainable materials and energy-efficient processes.

Q4: What are the primary components of a clay brick-making machine?

A4: A clay brick machine typically comprises a feeder, extruder, cutter, dryer, and kiln. Some advanced models may also include automated controls and sorting mechanisms for enhanced efficiency.

Q5: How do buyers ensure the quality of clay brick machines?

A5: Buyers can ensure quality by sourcing from reputable manufacturers, checking for international standards and certifications, and reading reviews and testimonials. It may also be helpful to request demonstrations and visit manufacturing facilities.