(4850 products available)

Cable hoses are essential in the construction of equipment and machines that protect cables and pipes from external elements. These hoses are important in several industries, including automotive, aerospace, and electronics. As a result, there is always a demand for cable hoses.

Wholesale buyers are looking for China manufacturer cable hose in order to meet the demand in their industries. They need to understand the various kinds of cable hoses that are available so they can order the right kind for their industry. Here are some of the different types of cable hoses:

Metal Cable Hose

A metal cable hose is a cable protection tube made of metal. It protects electrical wires and cables from heat, water, dirt, and other materials. These hoses are usually made from materials like aluminum and stainless steel. At one end, a metal cable hose is open so that cables can be inserted easily. It then closes on the other end, which may be crimped or welded.

Spiral Cable Hose

A spiral cable hose is used to arrange and protect cables that are installed in a spiral motion. It is flexible and can stretch, making it ideal for use in machines and devices that move around. A spiral cable hose is commonly found in robotics, automated systems, and industrial machinery.

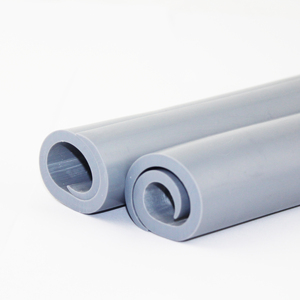

Plastic Cable Hose

A plastic cable hose is a tube used to protect and organize electrical wires and cables made from different types of plastics. It is lightweight, easy to install, and can be found in various colors and sizes. A cable hose is commonly used in automotive wiring, electronics, and appliances.

Spiral Cable Wrap

A spiral cable wrap is a protective covering for wires and electrical cables in a spiral shape. It is made from different materials like plastic or metal. This cable wrap is flexible and offers good protection against abrasion and other external elements.

Protection:

Hose pipes protect cables from physical damage, impacts, abrasion, and environmental factors like moisture, UV rays, and temperature extremes. This is especially important for cables installed in areas with a lot of foot traffic or exposed to harsh weather conditions. The cable protection hose also prevents rodents and other pests from chewing on the cables, which could cause short circuits or fires.

Heat Dissipation:

Cables often generate heat when they carry electrical currents. The cable ducting allows for proper air circulation around the cables, thus preventing overheating. Overheated cables are at risk of bursting into flames. So, this feature of the cable hose promotes the safe transmission of electrical currents through the cables.

Organization:

The corrugated pipe for cable management ensures that electrical cables are properly organized and bundled together. This prevents cable tangling and makes it easy to identify and access individual cables when required. This organization also enhances the aesthetic appeal of a space by reducing visual clutter caused by loose and tangled cables.

Flexibility and Bend Radius:

Cable hoses are flexible and allow cables to bend around corners without kinking or damaging. This is useful in installations where cables need to go through tight spaces and sharp turns. This feature also reduces stress on the cable jacket, which could cause internal cable damage or reduce the cable's lifespan.

Easy Installation:

Hoses are lightweight and easy to install. They come with accessories such as connectors, clamps, and zip ties that make the installation process straightforward. This reduces installation time and costs, benefiting contractors and engineers.

Durability and Longevity:

These cable hoses are made from materials such as corrugated HDPE and PVC that can withstand harsh conditions. They resist abrasion, UV degradation, and extreme temperatures. This reduces the need for cable replacements, thus lowering long-term operating costs for businesses and homeowners.

Cable protection and management have evolved over the years. Manufacturers have developed innovative solutions to safeguard and organize cables and wires. This has led to the introduction of different products designed for specific applications and industries. As such, there are different scenarios for using cable and wire protection hoses, including:

Automotive Industry

Cable and wire protection hoses are widely used in the automotive industry. This includes cars, motorcycles, trucks, and other automotive vehicles. For instance, manufacturers use them for engine compartments, wheel arches, chassis, and areas near hot surfaces. These conduits shield electrical wiring from heat, abrasion, and mechanical damage. They also prevent wires from getting snagged or cut in tight spaces or areas with moving parts.

Aerospace

In the aerospace sector, cable protection solutions are designed for lightweight and high-strength applications. They are used in aircraft, spacecraft, and satellites. These products protect electrical wiring from mechanical damage, high temperatures, and radiation. They also ensure the safe and reliable operation of critical systems. These include navigation, communication, and power distribution systems.

Marine

Cable and wire protection hoses are extensively used in the marine industry. This includes ships, boats, and offshore installations. They are designed to protect cables from saltwater, moisture, UV radiation, and abrasion. These protection devices ensure the reliability of electrical systems in adverse marine environments.

Construction and Building

Cable and wire protection solutions are widely used in the construction and building industry. This includes commercial, residential, and industrial buildings. They are commonly used in electrical conduits, HVAC systems, and plumbing installations. These devices protect cables from abrasion, impact, moisture, and UV radiation. They also ensure the safety and reliability of electrical wiring in buildings.

Manufacturing and Industrial

Cable and wire protection devices are widely used in manufacturing and industrial settings. This includes factories, plants, and workshops. These products protect cables from abrasion, impact, heat, and chemicals in industrial environments. They also ensure the safe operation of machinery and equipment. This is because of the reliable transmission of electrical power and signals.

Electronics and Consumer Devices

Protection hoses are extensively used in electronic and consumer devices. This includes smartphones, laptops, and household appliances. The devices feature lightweight and flexible conduits. This makes it easy to protect and organize cables in compact and portable designs. These products prevent abrasion, overheating, and electrical short circuits in these devices.

When buying cable hoses in bulk, it is important to choose the right China manufacturer cable hose. Here are some tips to help make sound choices.

Consider the Manufacturer's Experience

When buying cable hoses in bulk, it is important to consider the experience of the manufacturers. Ideally, select a manufacturer that has been in the industry for a considerable number of years. Such manufacturers have extensive industry knowledge and experience. They are also likely to offer high-quality products and services. More importantly, an experienced manufacturer is probably a reliable business partner.

Examine the Cable Carrier Hoses

It is important to carefully examine the cable hose carriers for quality and durability. Look for attributes like smooth operation, reinforced bends, and steel tubes that offer protection against impact, abrasion, and crushing. Also, check if the hoses are flexible and have reliable load-bearing capacity.

Assess the Manufacturing Technology

Customer Reviews

Buyers should take the time to read the reviews and testimonials of previous customers. This will help them to understand the level of satisfaction that the manufacturer offers. It will also give insight into the quality of the products and the kind of customer service they can expect.

Communication

Good communication is important when choosing a cable hose manufacturer. Buyers should ensure that the manufacturer has a reliable support team that can answer questions and address issues promptly. Also, the manufacturer should have a well-established channel for communication.

Q1: What are the common standards for cable hoses?

A1: There are several standards for cable hoses, including international standards such as ISO 7396, IEC 61386-1, and IEC 61386-24. National standards, such as the China GB 14751-2009 and the GB/T 14831-2011, are also applicable.

Q2: What are the common sizes of cable hoses?

A2: The size of a cable hose varies depending on the number and size of cables it is designed to carry. Common sizes include 50mm, 60mm, 70mm, 80mm, and 90mm. Buyers can also get customized sizes from a China manufacturer cable hose.

Q3: Are cable hoses flexible?

A3: Yes, cable hoses are flexible. They are designed to bend and curve easily, allowing them to be routed around obstacles and tight spaces. This is especially important in dynamic applications where cables and hoses are constantly moving.

Q4: How does one determine the right cable hose for a specific application?

A4: Consider factors such as the type and size of cables or hoses, operating conditions, environmental factors, and any specific requirements or regulations. It is also advisable to consult with a cable hose expert or manufacturer to determine the ideal option.

Q5: Are cable hoses easy to install and maintain?

A5: Yes, cable hoses are generally easy to install and maintain. They come with installation instructions, and proper installation is crucial for optimal performance. Regular maintenance involves inspecting the hose for signs of wear or damage and ensuring it is clean and free of debris.