(7992 products available)

The CE ISO foam machine is an essential piece of equipment for expanding foam production. Several machines exist, each with unique features and capabilities for various industry needs.

Foaming machine with a foam generator

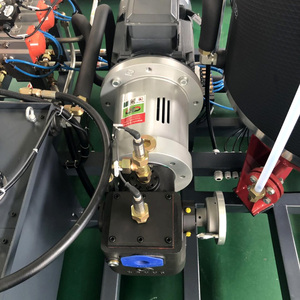

The foam machine with a foam generator is the most common type of machine for foam products. It uses the foam generator to create the foam from the chemical mixture. It usually has air compression as its driving force. Here is how it works:

The chemical mixture is kept in a tank where it gets stirred. While this happens, the air foam generator injects air into the mixture. This results in a reaction that blows the mixture into foam. It is often used to produce foam in pillows, seats, and mattresses.

Pressure foaming machines

Unlike the foam generator machines that depend on air, pressure foaming machines use injection under pressure to create the foam. It mixes the chemicals in precise amounts using a high-pressure pump. This precision creates a consistent and detailed foaming process.

The pressure foaming machine works by injecting the chemical mixture into a foam chamber. Air is then pumped into the chamber at high pressure. This causes the chemicals to expand and form the foam. It is commonly used in parts like seals, gaskets, and insulation.

Foam machine with a whip (or whisk) attachment

This type of machine uses a whipping attachment to create the foam. The attachment whips air and the chemical mixture together. This technique incorporates a lot of air into the mixture, and it can be done without any external power source. The foam produced by whip foaming machines is lightweight and used for decorations, crafts, and light insulation.

Continuous foam pouring machines

These machines offer a constant flow of foaming material that can be directly poured into molds or onto surfaces. This process leads to quick production rates, making it suitable for large-scale manufacturing. Continuous foam pouring machines are perfect for creating foam insulation, cushioning materials, and surfacing treatments.

Application

Foam machines can be applied to diverse fields, including construction, packaging, bedding, seals, soundproofing, and anti-slip surfaces. In addition, they can also be utilized as protective and insulating coatings, as well as for crafting customized foam products and prototypes.

Materials Compatibility

Foam machines can be applied to diverse fields, including construction, packaging, bedding, seals, soundproofing, and anti-slip surfaces. In addition, they can also be utilized as protective and insulating coatings, as well as for crafting customized foam products and prototypes.

Mixing Speed & Pressure

Mixing speed and pressure help ensure proper chemical reactions and foam formation. Typically, the mixing speed ranges from 1500 to 3500 RPM, while the mixing pressure varies from 0.5 to 2.0 MPa. Controlling the mixing speed and pressure with precision can produce consistent foam quality and reliability.

Control System

The control system of a foam machine includes an interface, programmable logic controllers (PLCs), and monitoring and diagnostic capabilities. The control system allows operators to set parameters, monitor operations, and receive real-time feedback on machine performance. It ensures accurate control of foam production processes and facilitates automation and optimization.

Safety Features

Foam machines are equipped with various safety features to prevent accidents and protect the operator. These safety components may include emergency stop buttons, safety guards, pressure relief valves, thermal overload protection, and safety interlock systems. Safety guards prevent injuries by keeping body parts away from moving components. Pressure relief valves can avoid excessive pressure, protecting the machine and the foaming products. Thermal overload protection can avoid the machine from being bumped to a higher temperature, etc. Those features cooperate, reducing risks and ensuring a safe environment for operators as well as the surrounding people.

Essential maintenance and inspection routines ensure foam machines perform consistently and steadily. Here are some helpful tips:

CE ISO-certified foam machines have multiple uses across diverse industries due to their ability to produce foam quickly and efficiently.

One common application of CE ISO-compliant foam machines is in the food and beverage sector, where they are used to make whipped cream, cappuccino, and beer foams, among other types of foams. Such machines are fitted with specific nozzles for creating distinct foam types. Using them can help improve product quality and enhance customer satisfaction.

In the packaging industry, CE ISO-certified foaming machines create polyethylene (PE) foam, which is widely used in protective packaging and cushioning. This packaging minimizes the risk of damage to goods and products. It also absorbs shock, thereby safeguarding the packaged products. Moreover, foam machines can be used to manufacture custom-sized foam inserts and cushions.

In the construction sector, CE ISO-compliant foam machines produce a variety of foams used for insulation, sealing, and spacing. Polyurethane foam, for instance, is commonly used in construction because it has moisture resistance, good insulation properties, and durability. It can also be dispensed into irregular spaces, where it expands to fill cavities and cracks.

Moreover, CE ISO-certified foam machines are used to create polyethylene foams employed in safety cushioning in the sports industry. Such foams are used to make goalposts, field and court liners, protective gear, and gym equipment. They help minimize the risk of injuries during sports activities.

Cars are often built with various foams for insulation, soundproofing, and cushioning. CE ISO-compliant foam machines can create such automotive foams. As a result, manufacturers use them to streamline production and improve efficiency.

When choosing a foam-making machine, it's essential to look beyond just the machine itself and consider the entire set-up, including storage capacities and transportation options. It's important to recognize that buying the machine is just the starting point of a more significant investment.

Investigate the available types of foam-packing machines, such as mobile foam machines, which work off portable generators, or those with automatic or semi-automatic functions. Please appropriately assess the production line and items to be packed, considering whether the quality and quantity of packaging requirements would be better suited to an automatic or semi-automatic machine.

Consider how items are packaged, including what kind of packaging is needed and how fast things need to be done. Think about whether it would be better for things to be put in bags or boxes and how much of a foaming agent is required to pack them efficiently. Please look into whether it's more efficient to have something integrated into production, like a conveyor belt system where foam can be applied continuously, or whether it would be better to have a separate, more portable system.

The simplicity of use, cleaning, and maintenance, as well as the machine's reliability and performance, are crucial. Ensure that the foam machine chosen has straightforward operations, easy-to-clean components, and low-maintenance needs, and also evaluate the device's dependability and efficiency.

Carbon footprint and environmental effects are practical concern. Please prioritize selecting a foam machine that minimizes unnecessary energy waste to help support an environmentally friendly approach through responsible energy use.

Q1: What are the current trends in the global foam machine market?

A1: The global foam machine market is witnessing significant growth. The increasing demand for foam in various end-user industries such as packaging, automotive, furniture, and others is driving the market.

Additionally, the trend of eco-friendly and sustainable products is boosting the demand for foam machines that produce biodegradable and recyclable foams. The technological advancements in foam machine production are also contributing to the market growth.

Q2: What substances can the foam machine inject use to generate foam?

A2: In commercial settings, the foam machine is typically filled with air and one part of the foam insulator. However, some specialized foam generators can use various gases and substances to create foam, including the following: Carbon Dioxide (CO2); Water; Protein-based foaming agents; Alcohols or hydrocarbons.

Q3: Are ISO CE-certified foam machines safe to use?

A3: Yes, ISO CE foam machines are safe. The CE marking indicates that the foam machine complies with essential safety requirements of European legislation, Also, the ISO certification shows that the machine manufacturers have established a quality management system.