(1907 products available)

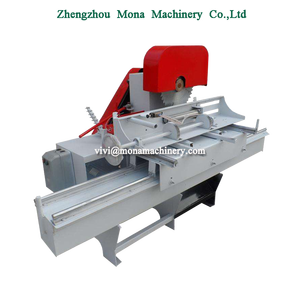

A band saw is an industrial cutting machine consisting of a long band of metal with a serrated edge forming a circular loop on two wheels. This machine is widely used in cutting materials with straight cuts and irregular shapes. It can cut various materials such as wood, metal, plastic, and meat, depending on the saw blade's design and size. There are many types of band saws for sale, two of the most common ones are stationary and portable ones.

Although not considered an official type, another way to look at a band saw is to think of it as a cutting application. Many suppliers sell bone band saws. These saws are specifically designed to cut through bones and are widely used in meat processing industries. Some features bone cutting applications have are stainless steel blades for corrosion resistance, antimicrobial blade coatings, and oscillating blade action for clean cuts.

Here are key specifications for some types of band saw Malaysias:

Capacity and Size

The cutting depth and width of the machine is known as its capacity. The cutting depth describes how far down the band saw can cut from the table to the blade's frame. The cutting width describes the maximum cut's width from the saw's blade to its vertical frame. For instance, a 14-inch band saw has a wheel that measures 14 inches. Its maximum cutting depth and width are 13 inches and 12.5 inches, respectively. The capacities and sizes are different for each band saw type.

Saw Blade

A band saw has two primary blades: the width and length. The saw blade width varies depending on the purpose of the machine. For instance, the saw width of a resawing band saw is quite big, so it can strand logs of wood into thinner pieces. The saw blade length for different machines is unique also. For instance, a 14-inch band saw's blade length is 93.5 inches.

Power Source

The power source of the band saw describes how the machine gets its energy to function. Several types are available, including hydraulic, electric, pneumatic, and internal combustion engine. Electric band saws are the most common of all the types, and they are used in large industrial spaces.

Cutting Speed

Some band saws cut with a high-speed motion. Others saw-cut at a low-speed rate. For instance, a band saw that has been designed for cutting metal will cut at a slower speed than one that has been designed to cut wood. The cutting speed is measured in feet per minute (FPM). It ranges from 60 FPM to 15,000 FPM, depending on the material and band saw type. The speed is directly linked to the horsepower of the motor that drives the blade.

With the right maintenance tips and guides, it is easy to keep the band saw in the best imaginable shape. Here are a few maintenance tips to consider:

Applications of band saw machines in Malaysia are numerous and diverse. In fact, this is the key saw machine that wood processing plants can't go without. Here are some common use scenarios for band saws in Malaysia.

Understand cutting needs:

When selecting a band saw in Malaysia, the first thing to do is to comprehend one's cutting needs. One should think about factors like material types, sizes, shapes, and cutting accuracy and capacity. This can also include determining both the maximum cutting thickness and width. Once this is done, there might be a need to consider an additional capacity for future needs or projects.

Consider the types of band saws:

Explore the different types of band saws available, such as vertical band saws in Malaysia and Portable Band Saws. Each kind has its own features and benefits. A vertical bandsaw machine with a fixed table is useful for making intricate cutouts in smaller workpieces, while a horizontal bandsaw with a moving table is ideal for cutting bigger workpieces. A portable bandsaw acts like a handheld cutting tool and is ideal for cutting pipes and rods.

Cutting capacity

Pay attention to the cutting capacity of the band saws. Consider the maximum thickness and width it can cut, as well as the overall dimensions of the machine. Ensure that the saw chosen has an adequate cutting capacity to handle the material sizes used in the project.

Blade selection

Choose the band saw machine that offers a wide range of blade options. Look at the available tooth profiles, widths, and materials. Ensure that the machine has the proper blade guides and tracking system to support the selected blades.

Control features

Consider the band saws with automated control features like digital displays, preset programs, and feedback systems. These controls offer more accurate and efficient cutting operations. Explore band saws with blade speed control functions to better understand how they control cutting performance.

Q: What materials can an industrial bandsaw cut?

A: The bandsaw is considered a versatile tool that can cut various materials, including wood, metal, plastic, foam, rubber, and ceramic. Using the right blade will give optimal results on the material at hand.

Q: What is the difference between a band saw and a table saw?

A: Both saws are used in the woodworking industry with similar functions. However, they are used differently due to their distinct features. The band saw is mainly used for cutting curves, resawing, and cutting irregular shapes. On the other hand, the table saw is used for making straight cuts with high accuracy. Cutting depth and cutting width are some distinguishing features between the two saws.

Q: What are the safety tips to consider when using a band saw?

A: When using a band saw, it is important to ensure that the blade guard is in a place. The blade guard is there to protect users from the moving blades. Another thing to do is to keep hands at least 5cm away from the cutting line. This cutting line is the area where the band saw will make cuts. Wearing safety glasses will help users identify issues clearly, so they should put them on when using the band saw. These are just a few safety tips to consider when using a band saw.