(411 products available)

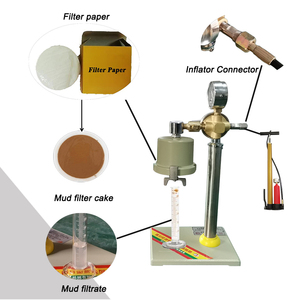

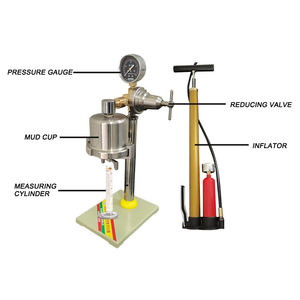

An API filter press is a solid-liquid separation device commonly used in industrial sectors to dewater sludge, slurry, or pulp. It comprises a series of plates and frames used to hold filters between the plates. When a pump introduces the slurry into the press, the filtrate passes through the clog, leaving the solid material behind. The filter press operates in three stages corresponding to the clog's passing phases: squeezing, filtration, and stripping.

The filter press has three primary types based on its operational mechanism:

There are also other machines based on their structure and usage:

The API filter press has diverse application across multiple industries.

Chemical industry:

The API filter press is widely used in the chemical industry to separate solids from liquids. It efficiently removes impurities from chemical products, resulting in high-quality chemicals.

Mining and metallurgy:

In the mining and metallurgy sector, the filter press is employed for ore tailings dewatering, concentrate separation, and extraction solution clarification. It aids in reducing waste solid volume, enhancing material recovery, and improving process efficiency.

Food and beverage:

In the food and beverage industry, the API filter press is utilized for juice clarification, beverage filtration, and protein and starch recovery. It enables the separation of solid particles, such as fruit pulp and yeast, ensuring clear and pure final products.

Pharmaceuticals:

In the pharmaceutical industry, the filter press is employed for drug separation, purification, and concentration. It plays a crucial role in the production of active pharmaceutical ingredients (APIs), excipients, and other pharmaceutical additives, ensuring the quality and purity of pharmaceutical products.

Textiles:

The filter press is used in the textile industry for sludge dewatering, dye solution filtration, and oil and emulsions separation. It assists in removing solid particles, such as fibers and dyes, from liquids, contributing to the clarity and quality of textile processes and products.

Biotechnology:

In the biotechnology field, the API press filter is utilized for cell separation, clarification of fermentation broths, and protein recovery. It facilitates the separation of cells, microorganisms, and other biological solids from liquid streams, enabling the recovery and purification of valuable bioproducts.

Feed Characteristics Analysis

Analyze the features of the feed. Examine the viscosity, solid content, temperature, and chemical properties of the liquid materials to be filtered. Considering the characteristics of the feed helps select suitable filter cloths and filter plates.

Cake Discharge Methods

Consider the filter press' cake discharge methods. Depending on the production needs, choose the manual, semi-automatic, or fully automatic filter press. Fully automatic or semi-automatic models could improve productivity and efficiency.

Sizes and Capacities

Select the right sizes and capacities for the filter press according to the amount of liquid to be processed and the filtration demand. Consider factors such as the number of filter plates, effective filtration areas, and maximum handling capacities.

Materials and Structures

Choose suitable materials and structures for the filter presses. For example, select anti-corrosive, high-strength plates for the filter plates and frames. For the filter presses used in high-temperature or corrosive environments, it's essential to select appropriate materials and designs for durability and stability.

Energy Efficiency

Consider the energy consumption and hydraulic systems of the filter presses. Choose models with energy-saving and efficient hydraulic systems to help reduce operating costs and environmental impact.

Integration and Automation

Consider the integration and automation functions of the filter presses. For example, the automatic control, data monitoring, and system integration capabilities of the presses. These functions can improve automation levels and simplify operating processes.

Maintenance and After-Sales Services

Consider the maintenance and after-sales services offered by the manufacturers. Choose those with reliable technical support and easily replace parts to ensure equipment maintenance and repair needs in the future.

Q1: Which filters apply in an API filter press?

A1: In an API filter press, the assembly of plates and membranes function as filters. The plates contain cavities for holding the material being filtered. On the other hand, the membrane/ pie filter press is a plate fitted with a membrane that can be inflated at the end of the filtration cycle.

Q2: What is the process carried out by an API filter press?

A2: An API filter press executes the process of cake filtration. It separates liquids from solids by pushing the slurry into a series of closed chambers created by filter plates.

Q3: What are the phases of operation in an API filter press?

A3: Three phases of operation take place in an API filter press. They include the filling phase, the filtration phase, and the cleaning phase. In the filling phase, the pump pushes slurry into the filter press. The solids get trapped in the filter press while the pump compresses the water and air bubbles on the solids. This task runs in the filtration phase. In the cleaning phase, the pump reverses and allows the water and air bubbles to flow back to the filter press.

Q4: Is the filter press automatic?

A4: The filter presses are automatic or semi-automatic. They combine the advantages of automation in the pumping system and the lock system for the filter press opening/closing.