(80584 products available)

Aluminium composite panel suppliers manufacture these ACPs in variegated types. They are based on different preferences and application requirements.

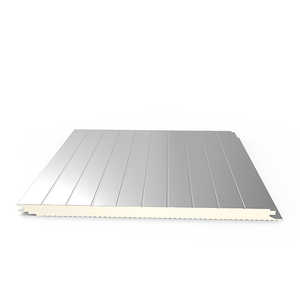

The standard ACP consists of two thin layers of aluminium and a non-aluminium core. Generally, these panels exhibit excellent durability, rigidity, and lightweight properties. Commonly used for internal and external facades, signage, and equipment cladding, these panels are the go-to for construction projects. They also offer affordability while providing good aesthetics and reasonable insulation properties.

Due to safety reasons, certain applications demand fire-resistant properties. Therefore, manufacturers make fire-resistant aluminium composite panel by using a mineral core or a specially formulated polymer core. These materials have a higher fire resistance rating than standard ACPs. Commonly used in high-rise buildings, commercial facilities, and areas sensitive to fire hazards, they mitigate fire spread and meet safety codes.

Another ACP that suppliers create is qualified as a “sound insulation ACP.” These panels come with a thicker or specially designed core that dampens sound vibrations. Because of this feature, they become ideal for environments where sound attenuation is critical. Such environments include airports, hotels, and concert halls. These panels not only insulate heat but also keep noise out of sensitive areas.

Anti-graffiti ACPs are specially coated to resist paints, stickers, and other forms of vandalism. Some coatings have easy-clean or anti-adhesive properties. This feature makes it easy to remove graffiti without damaging the panel surface. Because of this feature, they are used extensively in urban environments, transportation hubs, and public buildings, where graffiti poses an ongoing challenge. These panels help reduce maintenance costs and prolong the lifespan of exterior surfaces.

Lastly, suppliers produce photo ACPs. They are widely known as decorative panels. Manufacturers use direct printing methods to apply high-quality graphic designs, images, or patterns to the surface of these ACPs. Because of this feature, they are mainly used in advertising, retail interiors, and architectural facades to create visually striking displays. Besides being innovative, these panels are customizable, allowing businesses to tailor their branding and design needs effectively.

Buyers should keep in mind the durability of aluminium panels when purchasing in bulk. Properties such as corrosion resistance, temperature stability, and impact resistance make the panels durable.

Aluminium composite panel suppliers use aluminium in the manufacture of ACPs. The natural oxide layer on aluminium makes it highly resistant to corrosion. This feature ensures that ACPs maintain structural integrity over time when exposed to harsh weather conditions, such as humidity, rain, and saltwater. Therefore, their constant exposure to these elements will not cause them to weaken, which is why they are used in exterior applications.

Aluminium composite panels come with a certain degree of chemical resistance. This quality comes in handy in industrial or commercial settings where exposure to cleaning agents or chemicals is not uncommon. The resistant surfaces of the panels prevent damage from solvents, acids, and alkalis. Therefore, the panels maintain their aesthetic and functional properties for a long period.

Thanks to the proprietary polymers or materials used as the core of the panels, ACPs have exceptional resistance to temperature extremes. They do not expand or contract significantly amidst the temperature variations common in different climates. This property helps maintain a tight fit in the installation, which will reduce the risk of warping or cracking in the panel. Also, the panel will be usable for a long time regardless of the changing weather patterns.

Many ACPs have a low-density polyethylene (LDPE) or a fire-retardant polymer core. Such cores give the panels impact resistance, which is crucial for applications in high-traffic areas or hazardous environments. They enable the panels to absorb and withstand everyday knocks, hail, and even light debris without denting or breaking. They also make the panels long-lasting and ideal for use in façades, ceilings, and cladding.

These panels' long-lasting UV resistance comes from the external coating of the aluminium skins. They will not fade, discolour, or degrade even after constant sunlight exposure. This property makes ACPs a dependable choice for exterior facades in residential and commercial structures. This is because they retain their original colour and finish over several years. This factor also reduces the need for frequent repainting or refinishing of the panels.

These panels have countless attributes that are advantageous to their users. Some of these benefits include aesthetic value, insulation properties, and cost-effectiveness.

ACPs have a sleek and modern appearance. They make a building's exterior look more appealing. They are available in various colours, finishes, and designs, including wood and stone patterns. This availability allows for great flexibility in architectural design. In addition, their smooth surface reflects light beautifully. As mentioned earlier, this feature enhances the elegance of contemporary buildings and improves the overall ambiance.

One of the major benefits of ACPs is that it is lightweight, which makes it easy to handle and install. Their lightweight property also makes them suitable for insulating panels in roofing and wall applications. For instance, large sheets will not put a strain on the structure. Also, the ease of installation will lower the construction time and the overall costs.

Core materials like polyethylene in ACPs provide excellent thermal insulation. The insulation reduces energy costs in buildings by minimising heat transfer. This feature is especially beneficial in residential and commercial structures where energy efficiency is critical to maintaining comfortable indoor conditions. Therefore, users will save utility bills in the long run.

Aluminium composed panels are designed to withstand severe weather conditions. Such conditions include rain, wind, and UV radiation. This resistance guarantees the panels' long lifespan. It also ensures users' minimal upkeep and replacement consequences. Such features also make ACPs a very dependably used material in various climates across the globe.

Manufacturers consider ACPs to be highly cost-effective. They are when countering their prices with other cladding materials like glass or solid aluminium sheets. Their sturdy construction will extend the building's life, which means lower long-term maintenance expenses. Also, their energy-saving properties contribute to their cost efficiency. This feature also makes them a desirable choice among builders and property owners for budget-friendly solutions without compromising quality.

Buyers have to make certain considerations before placing bulk orders. These factors include quality, core material, thickness, customization options, and surface finishes.

The first factor buyers should consider is quality. Hence, aluminium composite panel suppliers should use high-quality aluminium and core materials to make them durable, weather-resistant, and visually appealing. One way buyers can ensure the panel quality they settle for is by asking for samples. It will help them to assess the material and workmanship before committing to a large order.

Aluminium composite panels have core materials that affect their strength, flexibility, and fire resistance. For instance, panels with polyethylene cores are lightweight and cost-effective. On the flip side, panels with mineral cores offer better fire resistance, making them ideal for high-risk environments. Buyers should settle for core materials that meet their projects' structural and safety requirements.

Panel thickness determines the ACP's rigidity and applicability. For example, thinner panels (around 3mm) are suitable for interior applications. These applications include decorative wall cladding. On the other hand, thicker panels (up to 6mm or 10mm) are better for exterior use. They are probably subjected to more weather elements. Buyers should consider the required thickness based on the intended application of the ACP.

The surface finish of aluminium composite panels greatly impacts their appearance and performance. Certain finishes like PVDF or polyester coatings offer enhanced UV resistance and durability. This factor ensures the panel's colour remains vibrant over time. Others have a mirrored or metallic finish that add an elegant look to the structure. Buyers should settle for finishes that suit their aesthetic preferences and performance requirements.

Lastly, buyers should consider the available customization options when placing bulk orders. Find out if the supplier can provide custom colours, sizes, and finishes to meet the project requirements. Furthermore, check the supplier's ability to maintain consistency in quality across multiple panels. It is vital for large-scale projects.

These panels' maintenance needs are minimal. Cleaning them with water and mild detergent will suffice. For tougher stains or graffiti, manufacturers recommend using specialised cleaners that won't damage the panel's surface. Regular cleaning also ensures the panels maintain their appearance and durability. Furthermore, an annual inspection for signs of discolouration, damage, or building wear will help extend the panel's life.

Some models incorporate recycled aluminium. In their own right, they are recyclable at the end of their life. This feature helps reduce the environmental impact of ACPs compared to other non-recyclable building materials. Also, certain manufacturers have sustainable practices, like using water-based adhesives and coatings, which further lessen their environmental footprint.

Certainly, it depends on their core material. ACPs with non-combustible cores have a higher fire rating. They are ideal for high-rise buildings and commercial spaces where safety is paramount. Buyers should look for panels with international fire standards certifications. These certifications include the European EN 13501-1 or the American NFPA 285 to ensure compliance with local building codes.

Yes, aluminium composite panels are fabricated to be easy to install. Their lightweight nature and ability to be cut into diverse shapes make them user-friendly. In addition, they can be fixed using various methods, including mechanical fasteners and adhesive bonding, suitable for any installation requirements. Their adaptability and ease of handling will cut down on the construction time and labour expenses needed for building projects.